“That Doesn’t Look Right”: How to Evaluate Glass Lining Damage [Part 1]

Description

We’ve written about the benefits of glass-lined equipment in other posts, but we thought it might be helpful to explore what happens when things don't go as planned.

If you follow our guidelines on proper operation, maintenance and storage/handling you can prevent bad things from happening to your glass-lined equipment.

However, we know that in the real world sometimes things happen…mistakes, accidents, misunderstandings. Use this post as a brief guide to give you an idea of what could be going on with your glass-lined equipment if something “doesn’t look right” to you

Below we’ve listed examples of glass damage that are broken down into mechanical and thermal types (we’ll cover electrical and chemical attack in next month's post). This information is also thoroughly outlined in Materials Technology Institute's Repair and Damage Assessment for Glass-Lined Equipment, written by Sal Falcone and Bert Moniz.

MECHANICAL FAILURES

Impact

Internal impact:

Internal impact occurs when something hard hits the interior lining surface. Generally speaking, you want to avoid dropping any object heavier than 450gr. from a height greater than 20 cm. When you are working in a reactor, it is important to pad the floor and mixing system before entering the vessel to prevent an accidental internal impact from a loose item or tool that is dropped. Repair for this type of damage involves a 3-piece plug for damage up to 10 cm and a patch for larger areas.

External impact:

While glass is quite strong in compression, it is weak in tension so a direct blow to the exterior of the vessel can cause a “spall” or star-shaped crack pattern to the interior glass lining. Avoiding a sudden external force to the reactor is an easy way to prevent this type of damage from occurring. It can be repaired using the same method used for internal impacts.

Hydroblasting:

Installing a wash-in-place system via spray balls and other type of pressure equipment is an effective way to keep your vessel clean. However, if the high-pressure cleaning exceeds 138 bar or if the water jet is less than 30 cm from the vessel wall, damage can occur (there are situations where greater allowances are acceptable, but this is a general best practice). Additionally, abrasive particles mixed with the water can contribute to hydroblast damage as can water sprayed on a specific area for a prolonged period of time and direct contact to repairs such as patches or plugs. In extreme cases, the glass lining can be worn down to the steel substrate. Reglassing is usually required to fix this type of failure.

Abrasion:

When particles that are harder than the glass surface contact it, abrasion can occur. This often happens at the edges of nozzles, baffles and agitators due to vigorous mixing. Most abrasive damage is minor and doesn’t require repair, though sometimes polishing may be required, and in extreme cases reglassing may be needed.

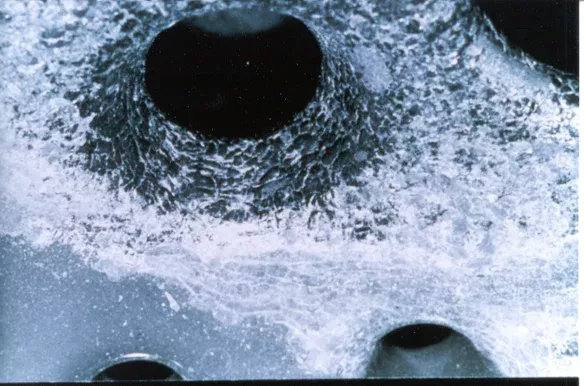

Cavitation:

Caused by condensation, pressure decrease, and chemical reaction, cavitation is the damage that occurs when bubbles collapse at the glass surface (who would think that bubbles can generate such an impact force?!). Incorporating Nitrogen into your process can help to subside bubble collapse and using spargers is also a way to combat cavitation. If damage is severe enough, reglassing of the damaged surface (vessel, agitator, and/or baffle) may be required.

Stress

Crushing:

Despite its compressive strength, improper flange makeup and uneven or over-torquing can crush glass. In addition to carefully selecting your gaskets and following proper flange assembly techniques, calibrated torque wrenches must be used to avoid excessive stresses. Epoxy putty is a suitable fix for minor damage. Other repair methods for flanges include outside metal or PTFE sleeves. Extreme cases require inside-outside metal sleeves.

Bending:

When piping systems are not adequately installed and supported, the connection to the vessel is subject to excessive tensile and compressive forces which can lead to bending damage. Bending damage is evident from the cracks that appear at the bending axis. This damage can go as deep as the steel substrate and necessitates the use of an outside metal or PTFE sleeve, or reglassing in severe cases.

Vibration:

When baffles, dip pipes and other accessories that are installed via nozzles are not sized and positioned properly, it can result in vibrations that can cause glass damage so widespread that the only solution is reglass. This can be prevented, however, by properly aligning your agitator and other internal components as well as being conscious of water hammer and using the right sparging device for steam injection.

THERMAL FAILURES

Shock

General thermal shock:

Any time your reactor experience a sudden change in temperature that is in excess to the recommended limit, you are exposing your vessel to potential thermal shock. Adding hot liquid to a cold vessel wall or conversely cold liquid to a hot glass surface creates an environment of increased tensile stress on the lining. This type of damage is usually so extensive that the entire vessel needs to be reglassed to repair it.

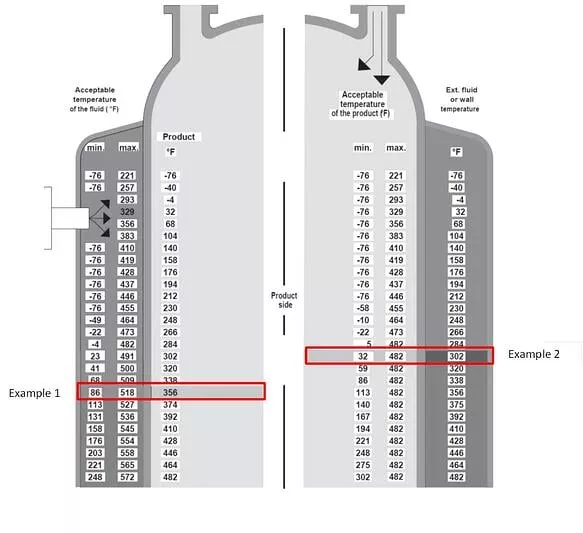

There is a simple solution to this though – just reference our handy “Maximum Allowable Thermal Shock – 3009 Glass” chart and you can easily determine the safe temperature differentials for 3009 glass lining. The chart is easy to read:

- The left side of the figure shows the acceptable temperature range of the jacket fluid based on the temperature of the product in the vessel. This data is needed when you are introducing a heating or cooling fluid into the jacket.

Example 1: If the glass-lined wall (and the batch) is at 180°C, the fluid introduction should be between 30°C and 270°C.

- The right side of the figure indicates the suitable temperature range of the product based on the current temperature of the jacket fluid. This data is needed when you are introducing product into the vessel.

Example 2: The reactor is to be charged when the glass-lined wall or fluid in the jacket is 150°C; therefore materials between 0°C and 250°C may be safely charged into the vessel.

MAXIMUM ALLOWABLE THERMAL SHOCK – 3009 GLASS

In general, the higher the operation temperature is, the lower the safe temperature differential. If you are ever unsure it is always best to consult with a professional who can give you the right guidelines.

Local thermal shock:

This term refers to thermal shock damage that is localized, for example, from a leaking valve that injects steam on a particular area of the glass-lined surface. Because the area is significantly smaller than general thermal shock which affects the entire vessel, a patch can sometimes be used as long as it can cover the entire damaged area.

Welding near glass:

One of the critical “don’ts” in glass-lined equipment care is “don’t weld components onto your equipment interior or exterior.” You should always contact your equipment vendor if any modifications need to be made to your vessel that would require welding. Welding and glass surfaces are generally are not a good combination due to the risk of thermal shock; welding on glass-lined equipment will almost always cause glass damage. Any major modifications can be made to the vessel during reglassing, such as changing the nozzle sizes, adding a nozzle, or adding supports. If you do attempt to weld on your own and cause damage to your vessel, the repair method depends on the size of the area and includes plugs, patches or even reglassing.

Stress

Restricted flexibility from large fillet welds:

Thermal shock is most prevalent at fillet welds between the vessel shell and jacket as well as at the top and bottom jacket closure rings. This is due to the high stress concentration in these areas. Addtionally, any build-up of sludge in the reactor jacket and attribute to thermal stress risks. By blowing down the build-up on a regular basis, you can avoid plugging the outlet nozzle diaphragm ring which will decrease chances of thermal stress damage. Since this type of damage usually extends tot eh substrate, reglassing is most often the only viable repair option.

Expansion of steel:

The steel substrate of a vessel can expand for a number of reasons, freezing of the interior contents and over-pressurization of the vessel being the two most common. This expansion results in a series of cracks to the lining. In the case of agitators and baffles, if liquid that accumulates inside the hollow centers freezes, the glass often falls off in long shards. Expansion of steel damage is so severe that reglassing is the only solution; there are times when the steel is so badly deformed that the vessel is deemed unusable.

By educating yourself about the different types of damage and how they can occur you can help ensure that this won’t happen to you. There is an abundance of resources to help you learn how to properly care for and maintain your equipment. By following the guidelines in our do’s and don’ts and best practices posts, your equipment can enjoy a long and prosperous life. Remember to check back next month as we continue this discussion on evaluating glass damage and touch upon electrical issues and chemical attack.