Hero

Filtration & Drying

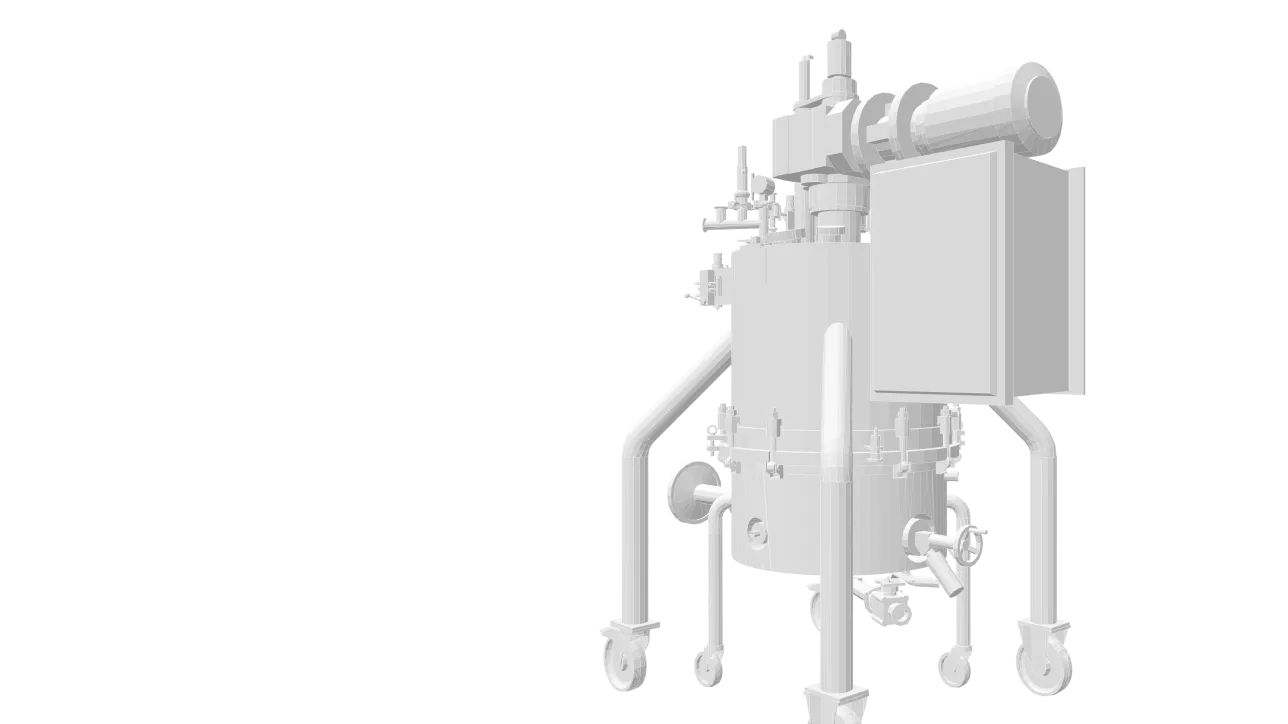

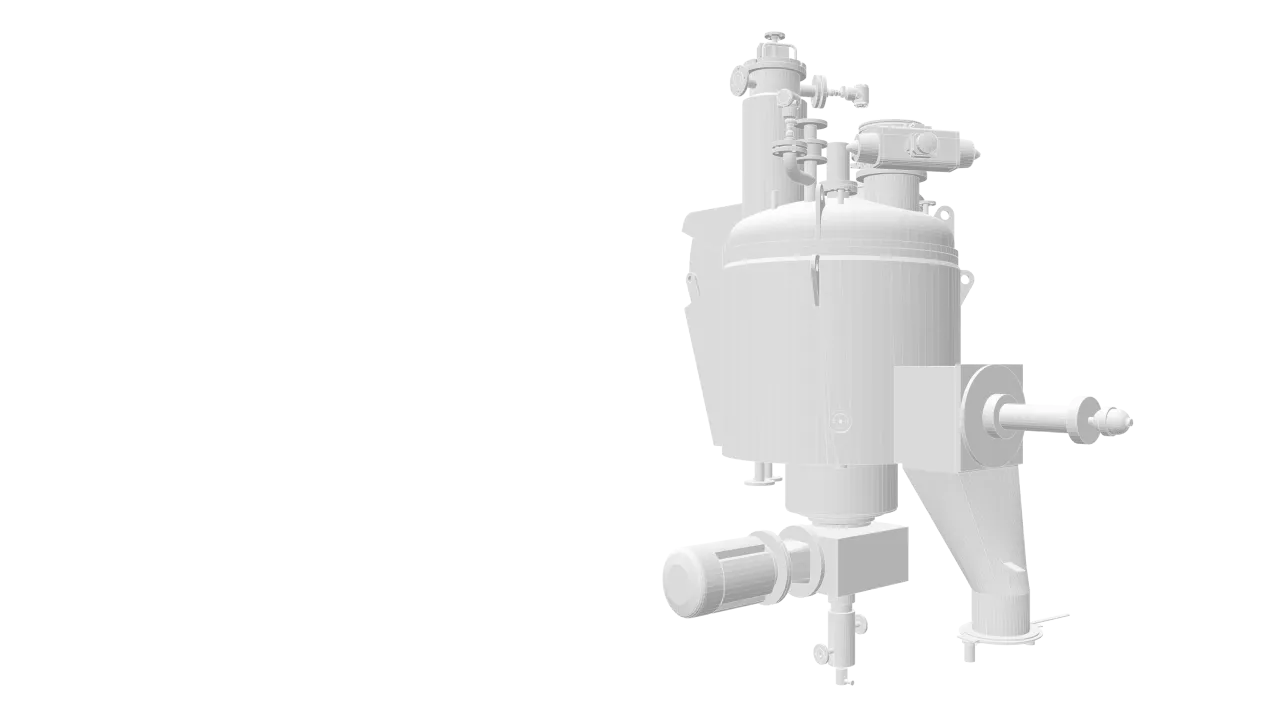

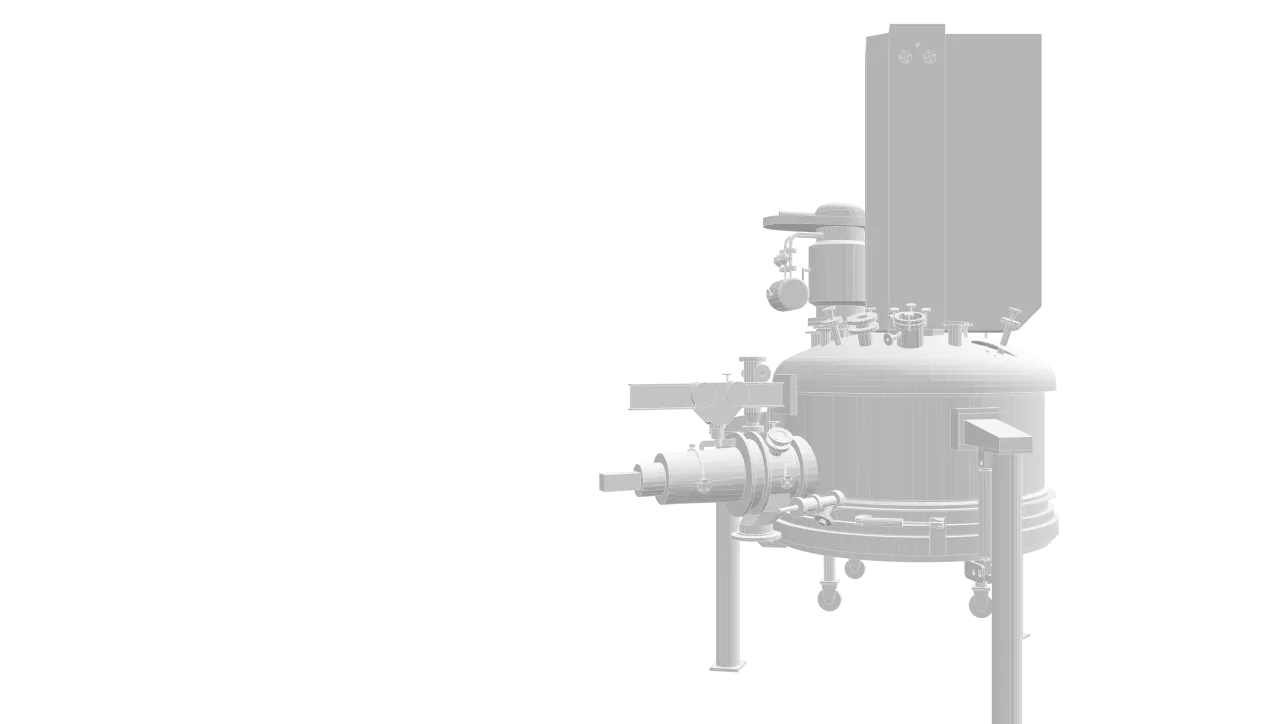

Pan Dryer

Dynamic vacuum drying of delicate, heat sensitive products

Alloy Filtration & DryingDrying

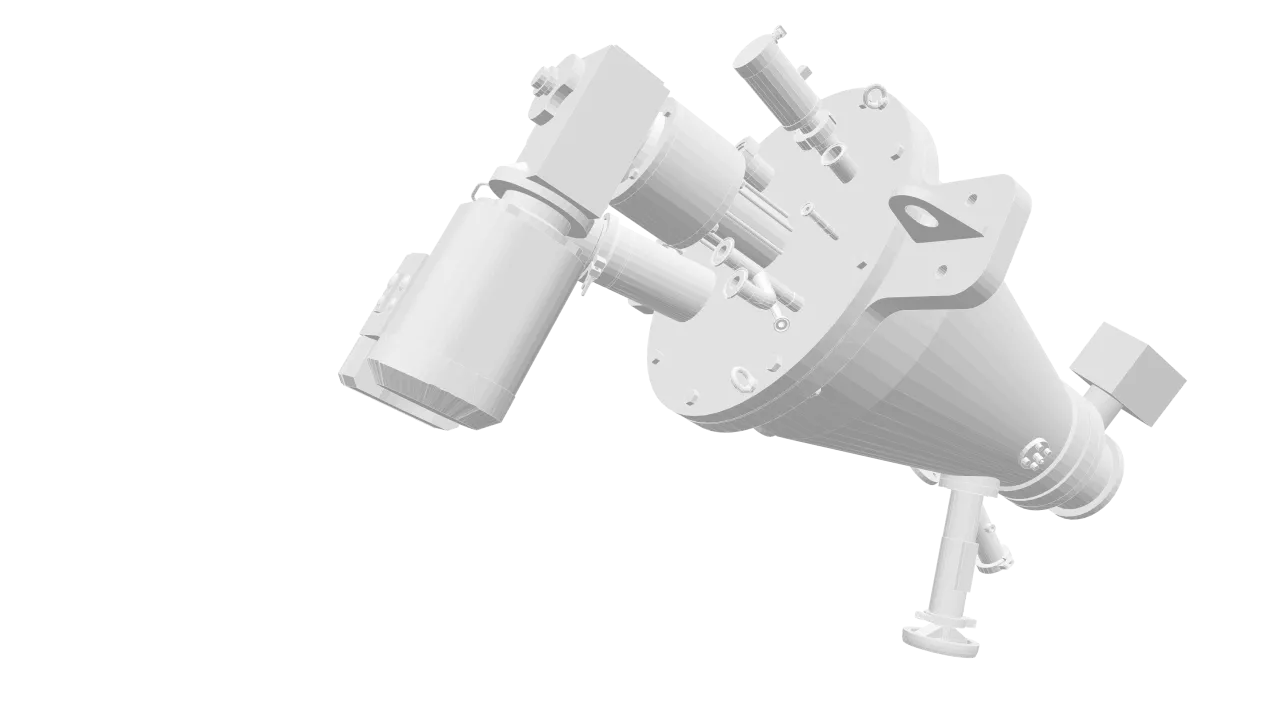

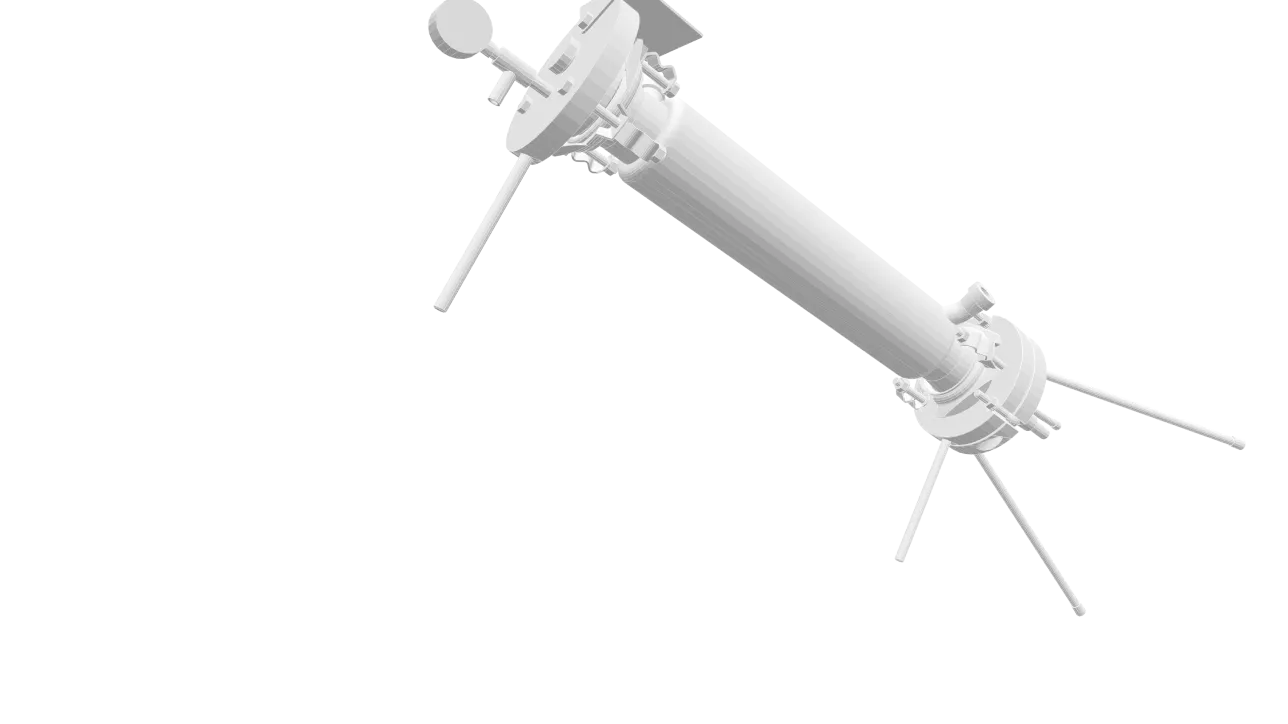

Horizontal Dryer

Unequalled application spectrum and extremely short drying times

Alloy Filtration & DryingDrying

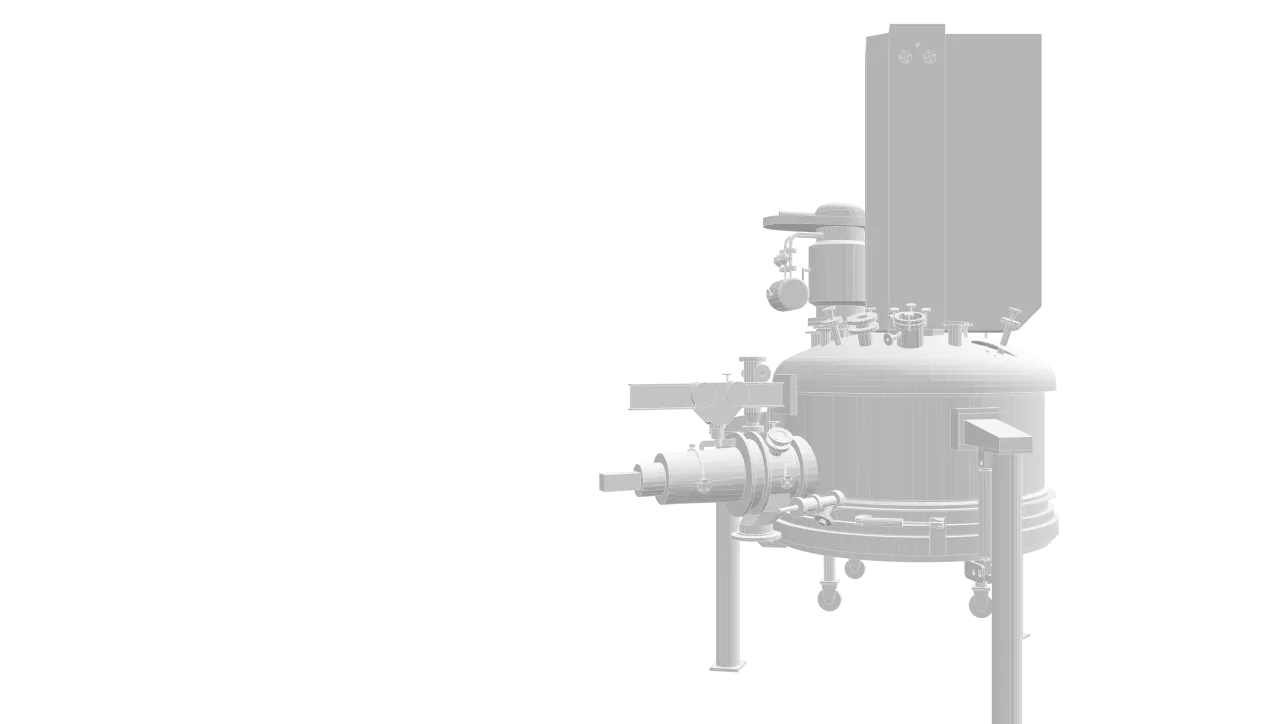

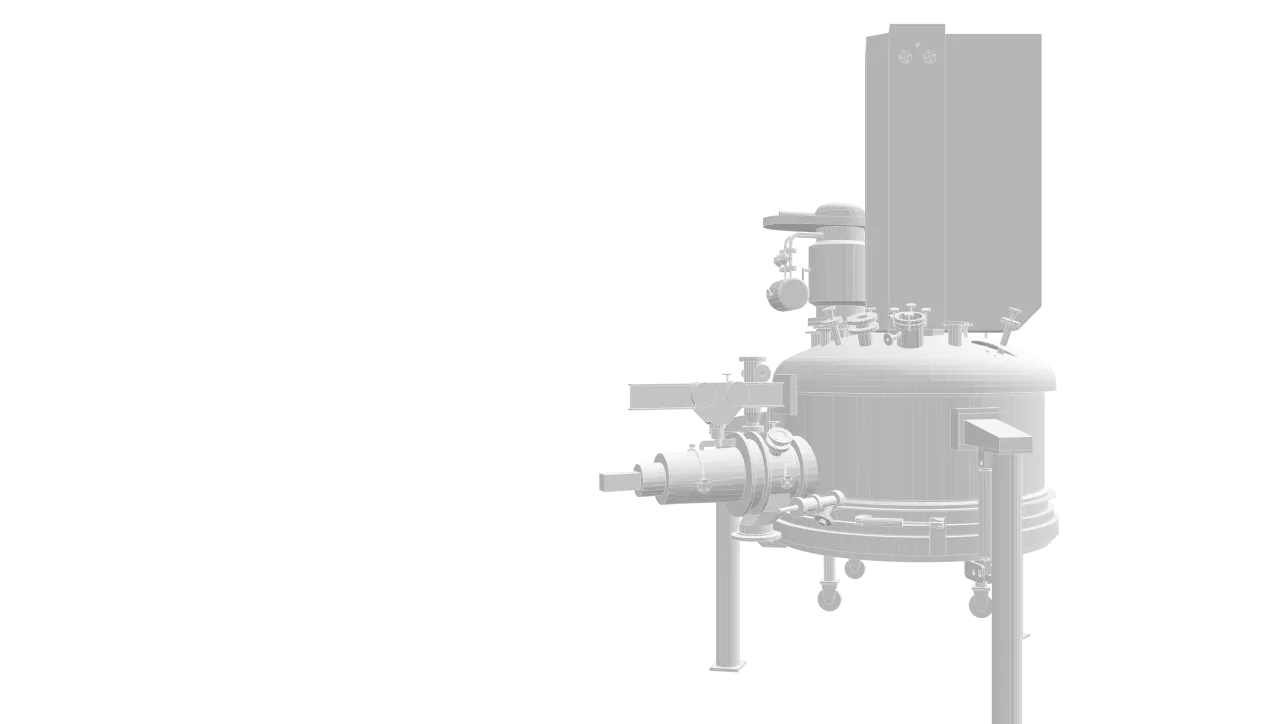

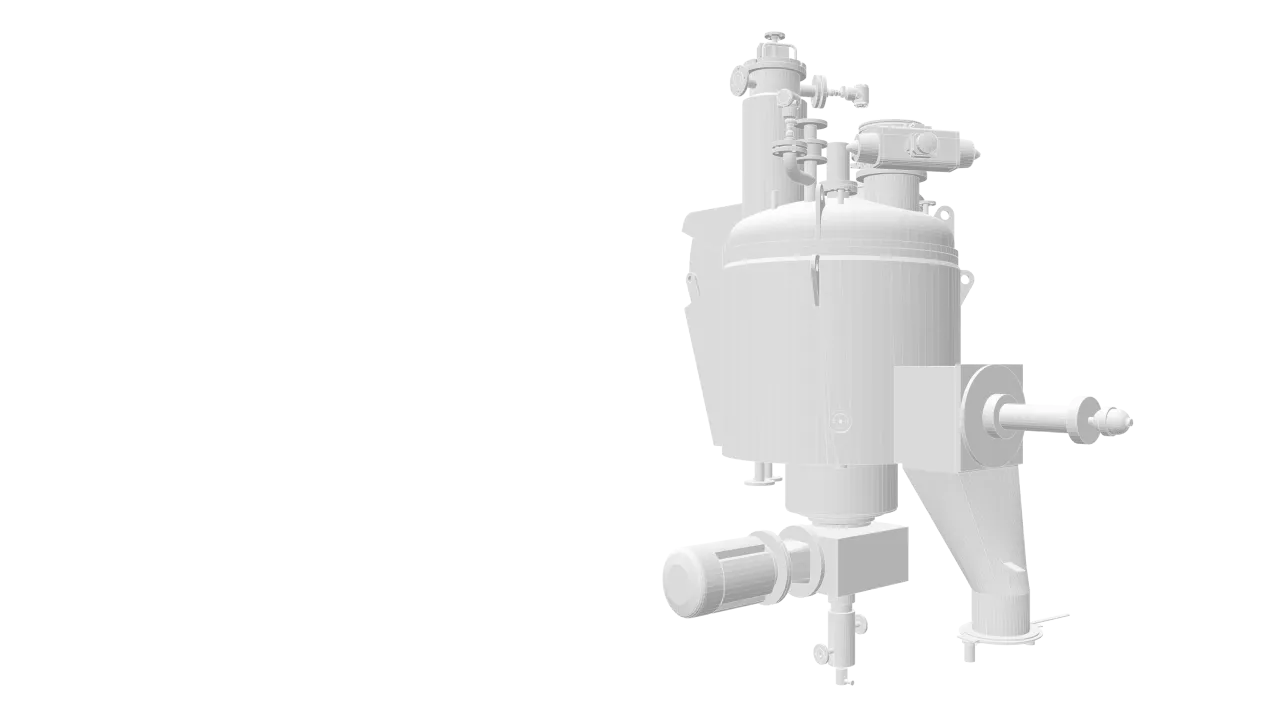

Roman, Manual Static Nutsche Filter

Simple, manually operated Nutsche Filter for liquid-solid separation

Alloy Filtration & Drying

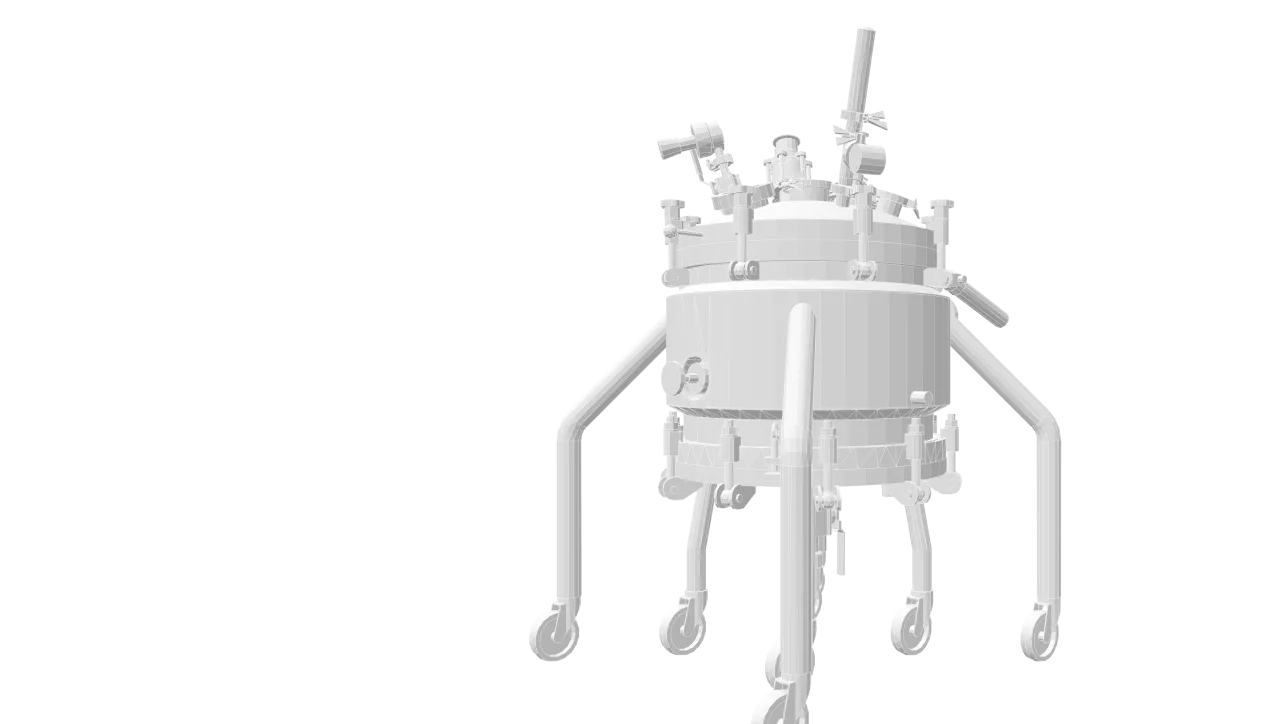

Table Top Filter

The Table Top Filter completes nicely our range of small sizes filters.

Alloy Filtration & Drying

Pocket Filter

Fast, safe demonstrations and tests of filtration, washing and drying.

Glass Filtration & Drying

Glass-Lined Filter / Dryer

When high quality steel do not satisfy the expectations anymore

Enamel Filtration & Drying