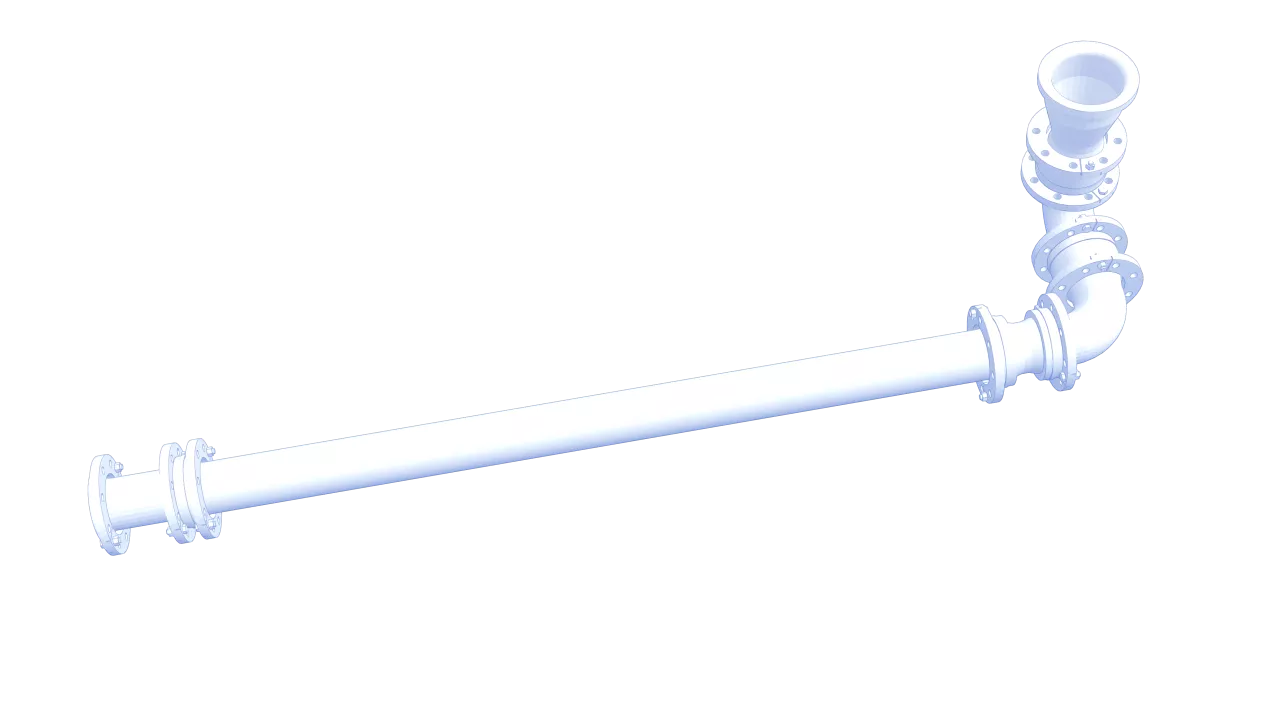

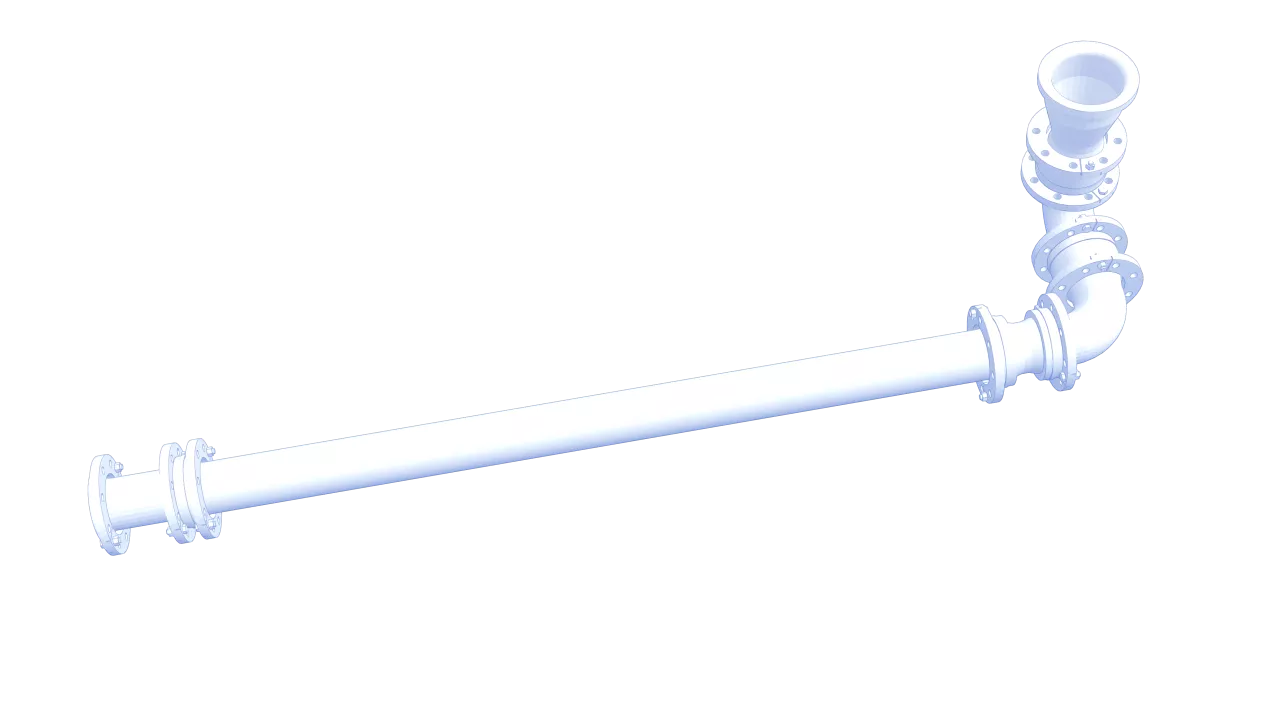

Glass-lined piping

Covered with DD3009 enamel, our glass-lined pipes and fittings are made with the same care used on all our equipment

Enamel Components & Accessories

Covered with DD3009 enamel, our glass-lined pipes and fittings are made with the same care used on all our equipment

Enamel Components & Accessories

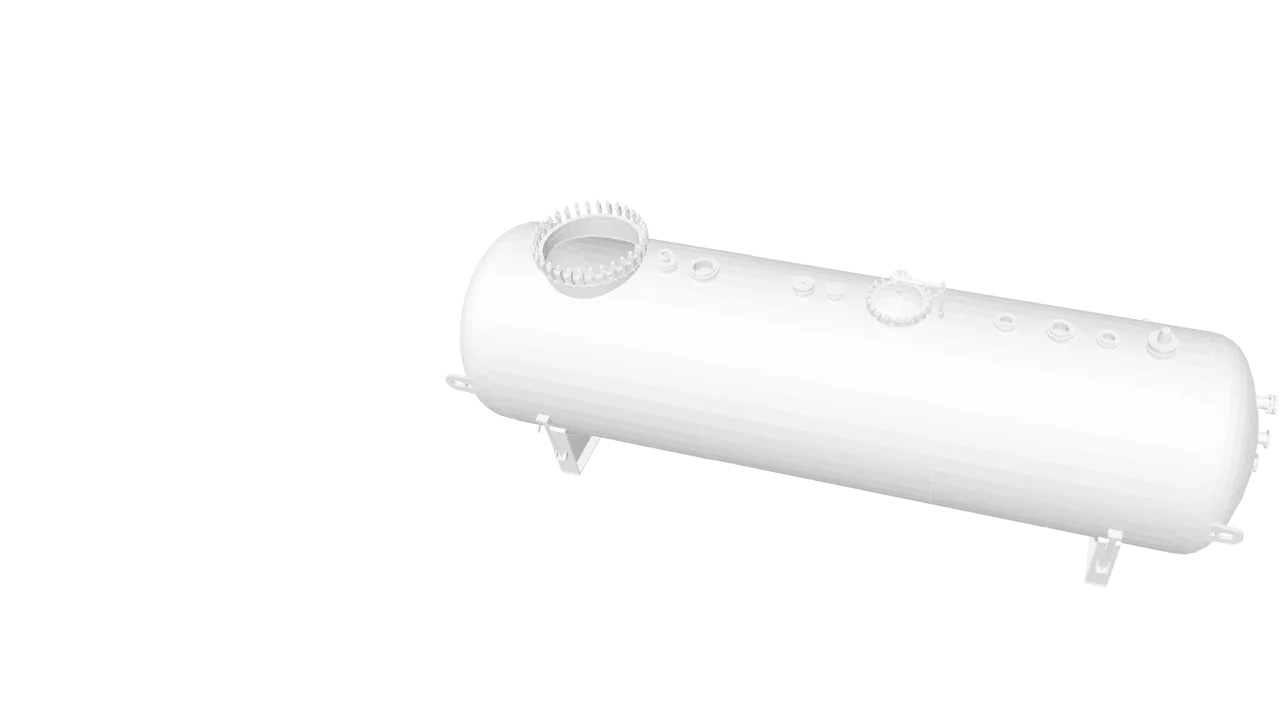

The glass-lined steel storage tanks can be designed for a working pressure of -1 / +6 bar and are equipped with manholes and nozzles according to your requests.

Enamel Storage

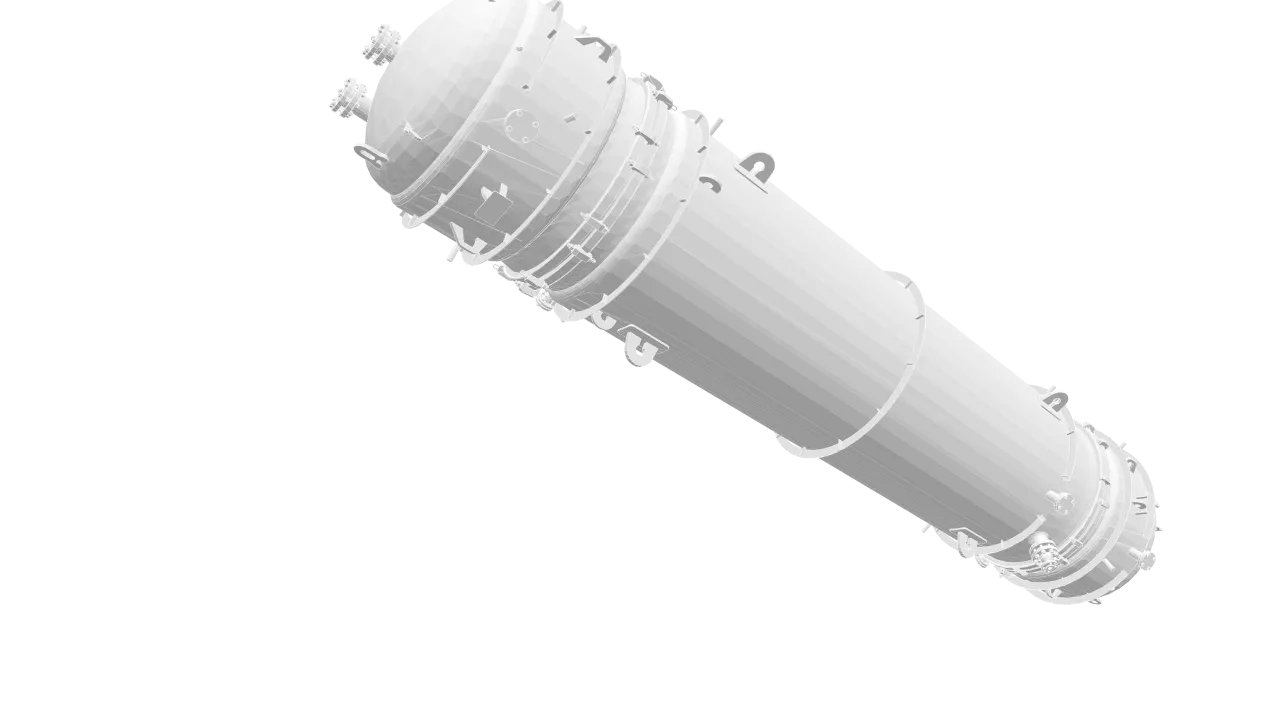

Our receivers are designed for an inner pressure of 6 bar/-vacuum and, if needed, 6 bar in the jacket.

Enamel Storage

Pharmaceutical applications have guided the design of this equipment

GlassEnamel Reaction / Agitation

De Dietrich offers an innovative Plug & Play system to take representative samples in highly corrosive environments

Enamel Components & Accessories

We are able to design and manufacture glass-lined columns up to DN 2400.

Enamel Storage

Covered with DD3009 enamel, our glass-lined pipes and fittings are made with the same care used on all our equipment

Enamel Components & Accessories