Hero

Distillation

Membrane technology

Technology for alcohols, solvents, aromas and odours separation

Alloy DistillationEvaporation

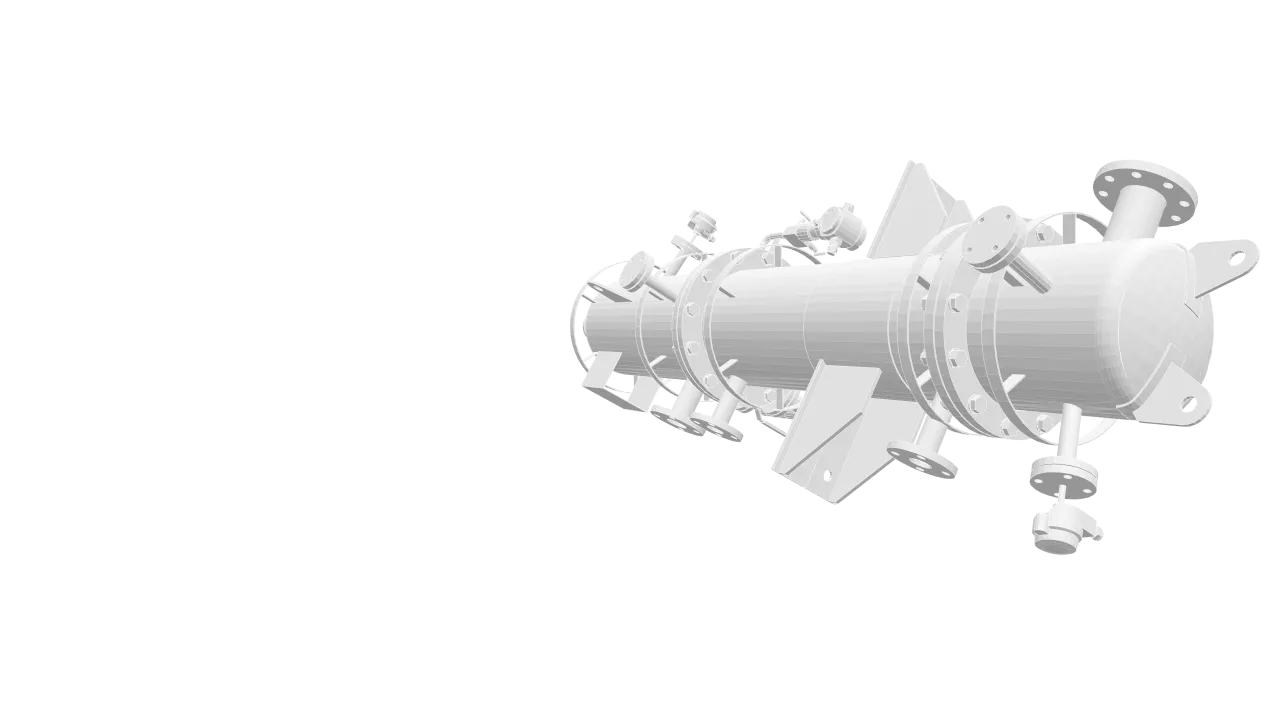

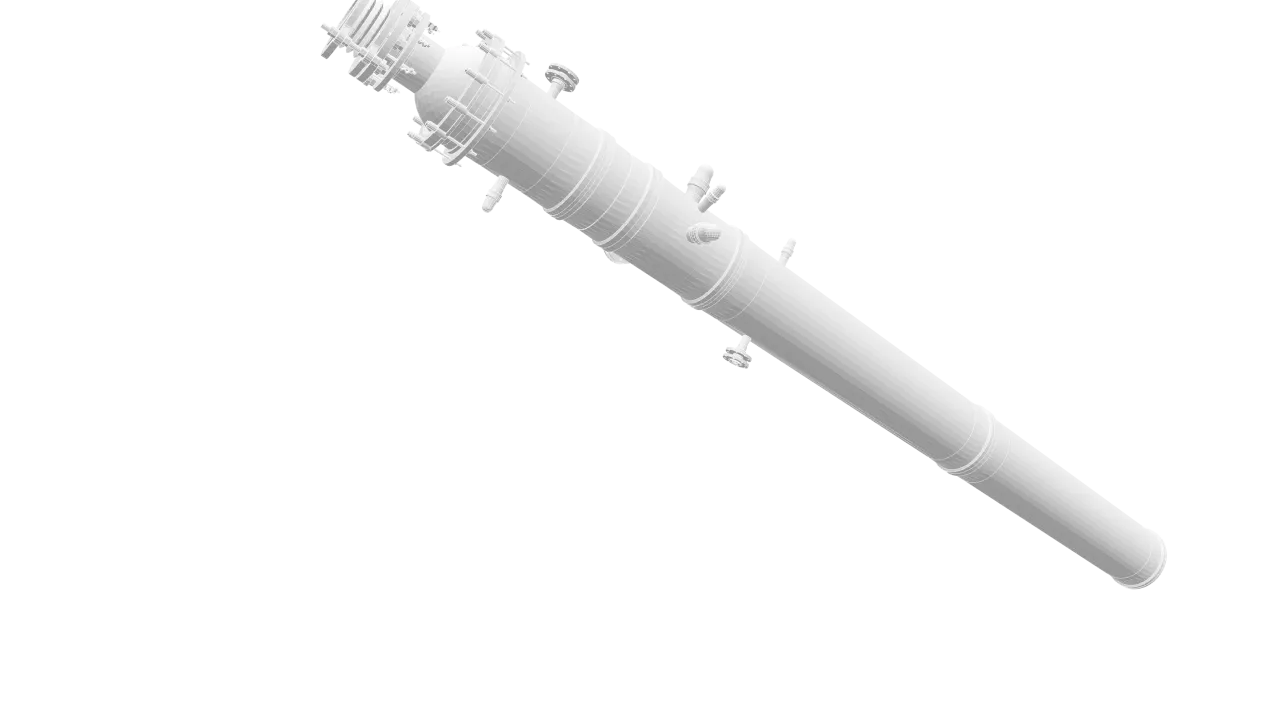

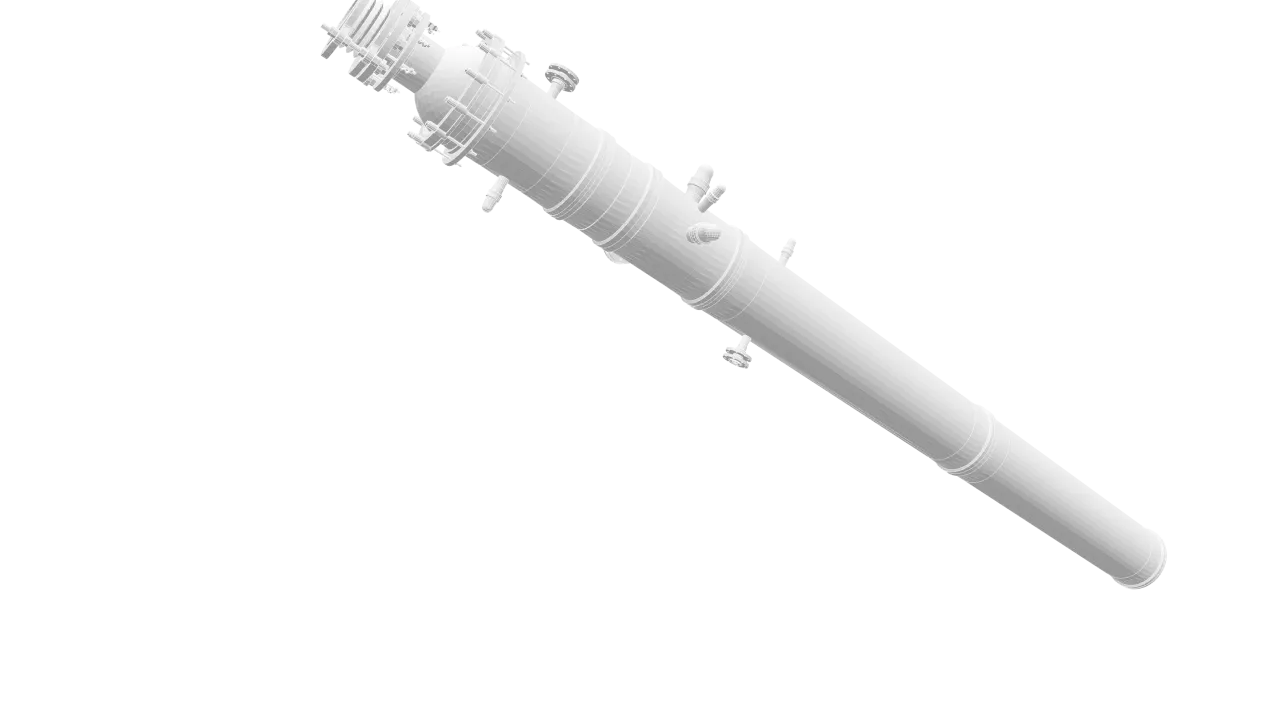

Horizontal Thin Film Evaporator

Best in class horizontal thin film evaporator

Alloy DistillationEvaporation

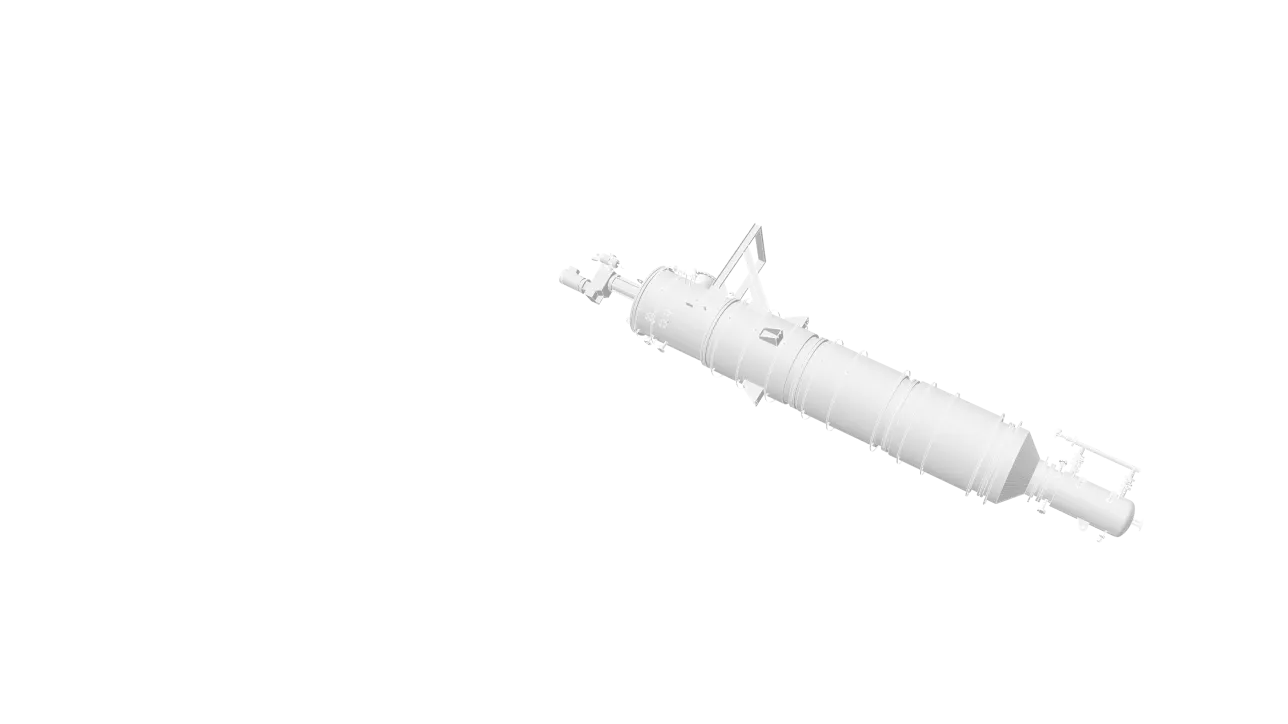

Short Path Evaporator

The unique evaporator for extraordinary applications

Alloy DistillationEvaporation

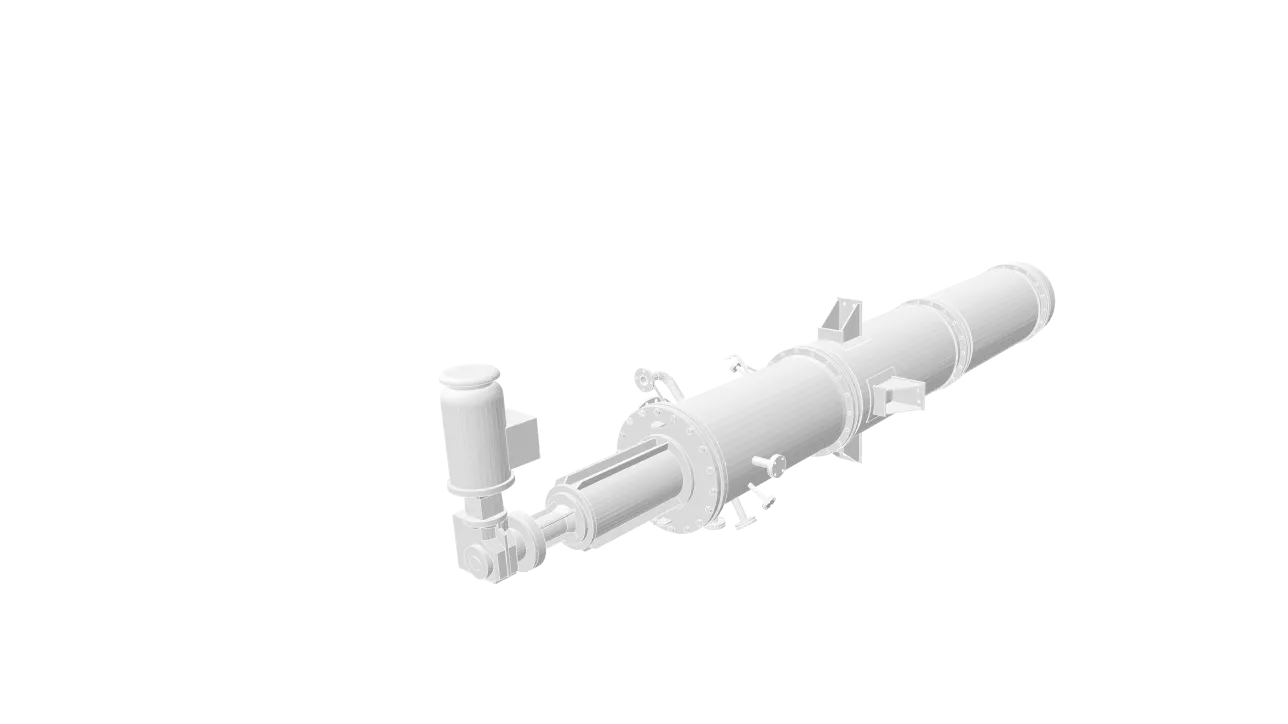

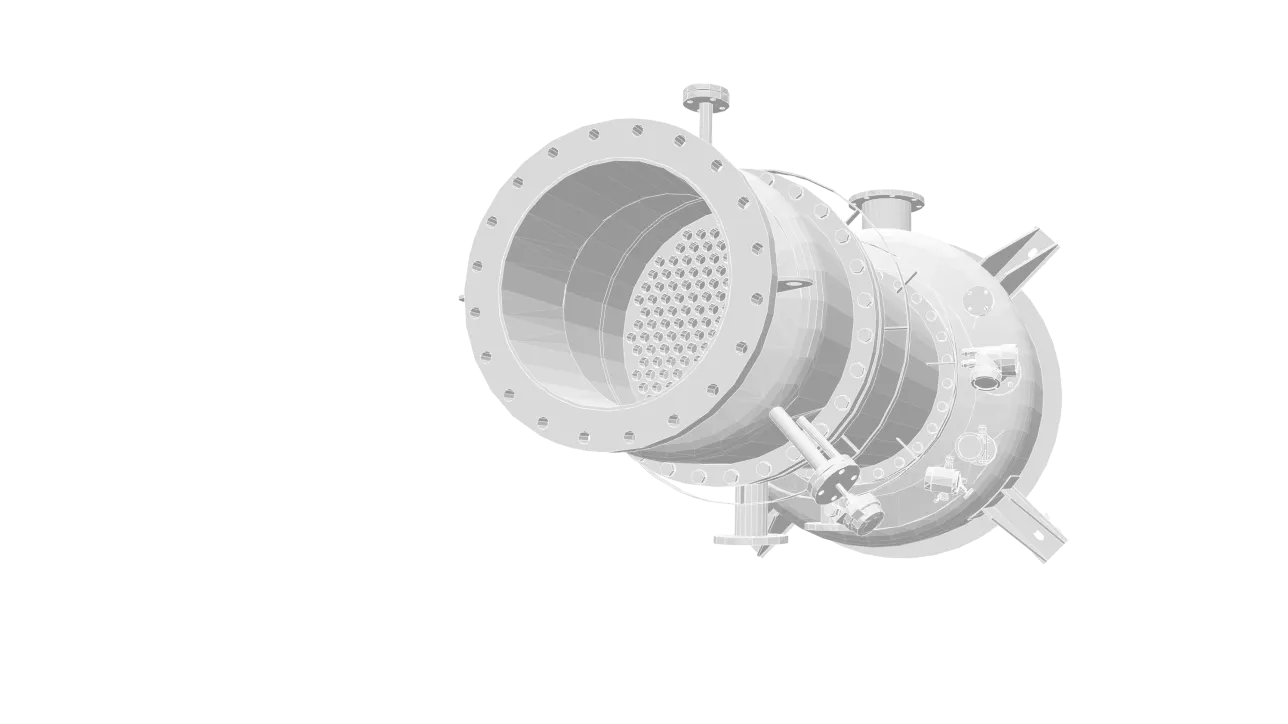

Force Circulation Evaporator

Robust equipment for difficult handle processes

Alloy DistillationEvaporation

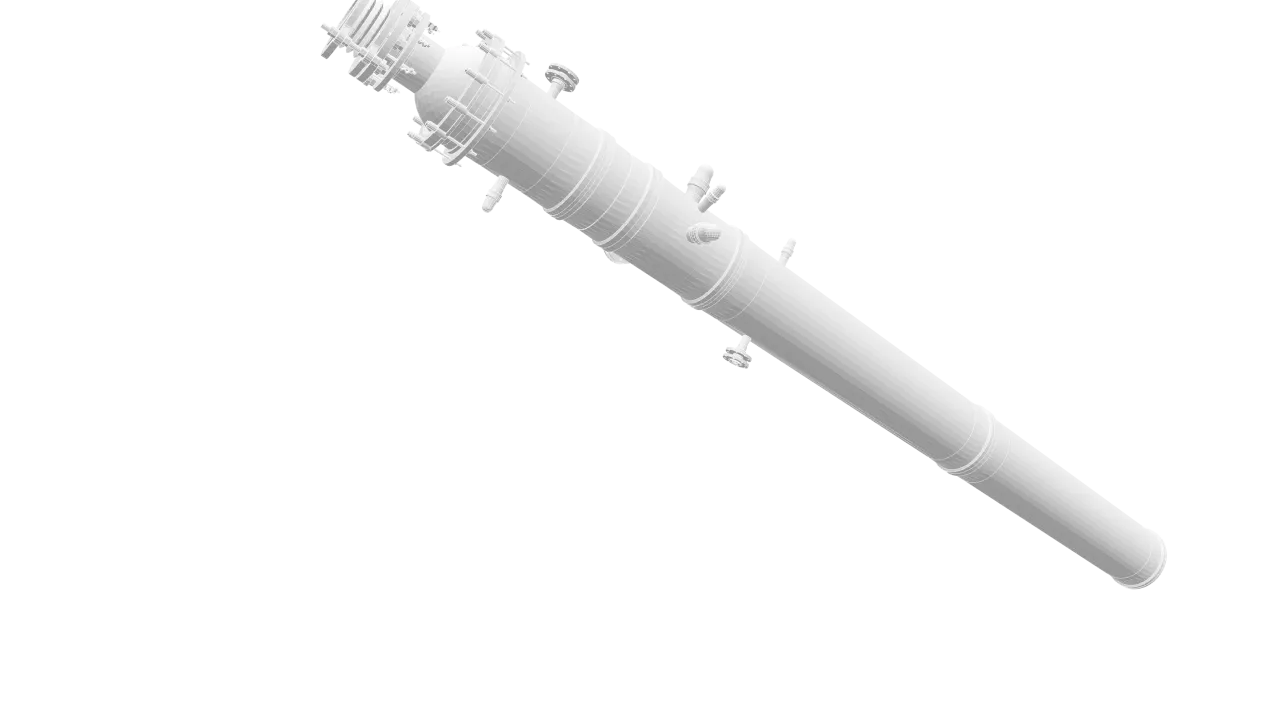

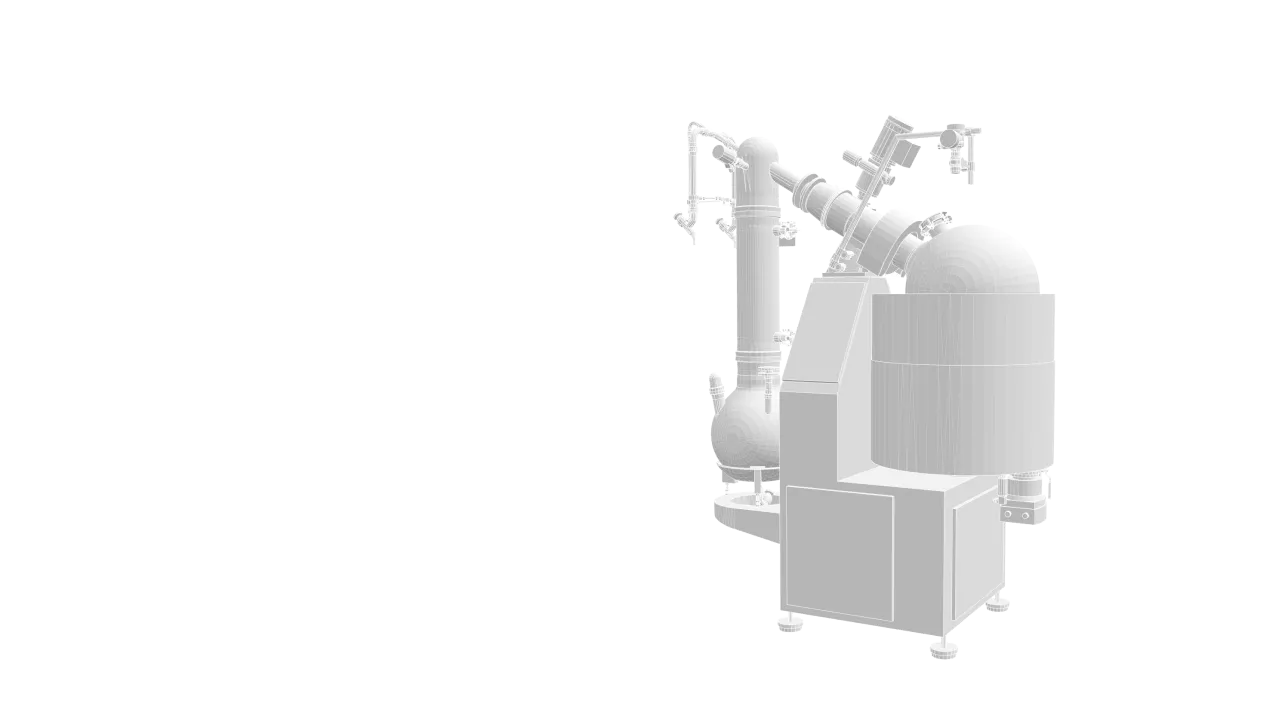

Rotary Evaporator

QVF® ROTADEST solution for solvent evaporation, crystallization, drying of suspensions, powders or granulates

Glass EvaporationDistillation