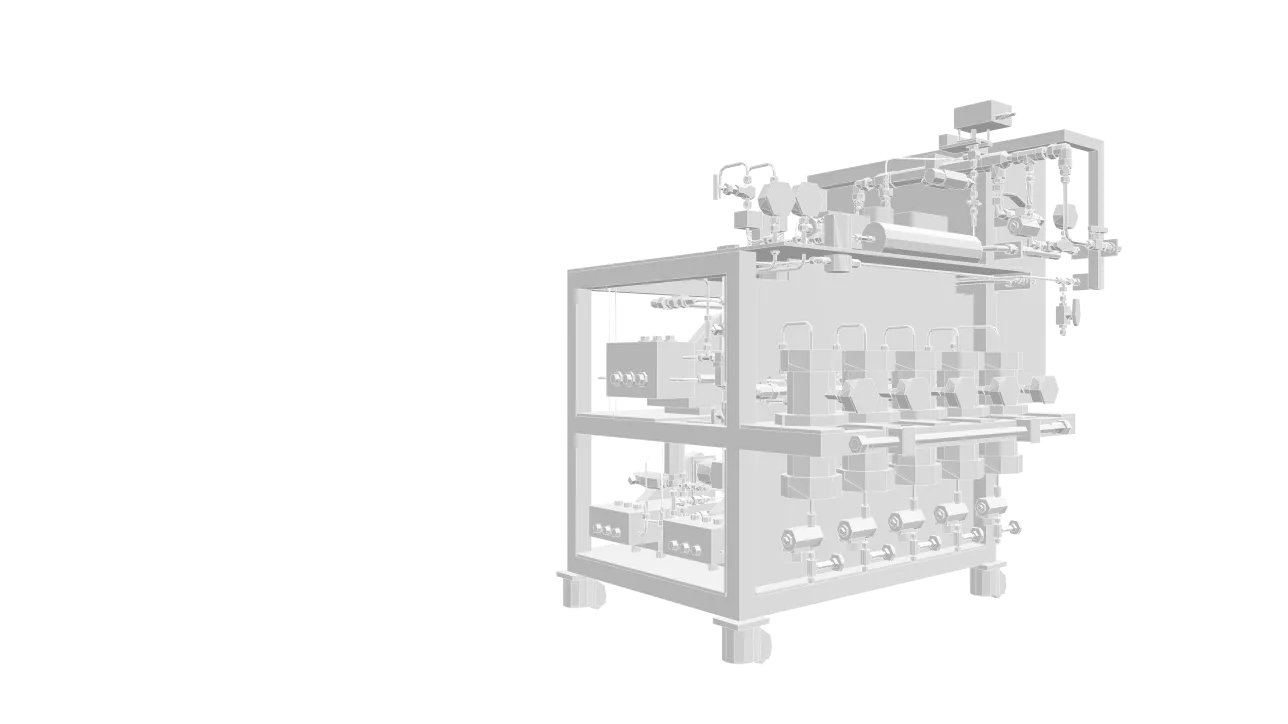

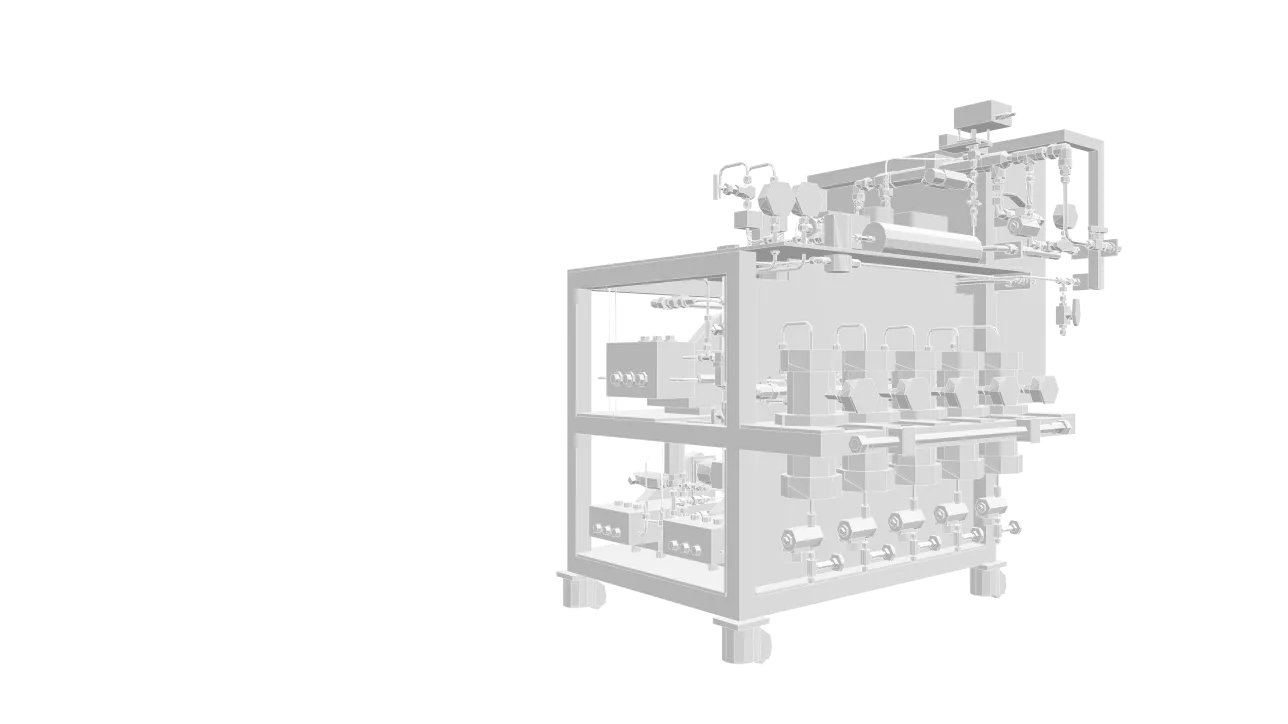

Hero

Process Systems

QVF® Shell And Tube Heat Exchangers

- Medium side corrosion-resistant - service side up to 6barg -

Glass Process Systems

- Medium side corrosion-resistant - service side up to 6barg -

Glass Process Systems