Powder Pumps

Efficient, contained powder transfer for safe and dust-free operations

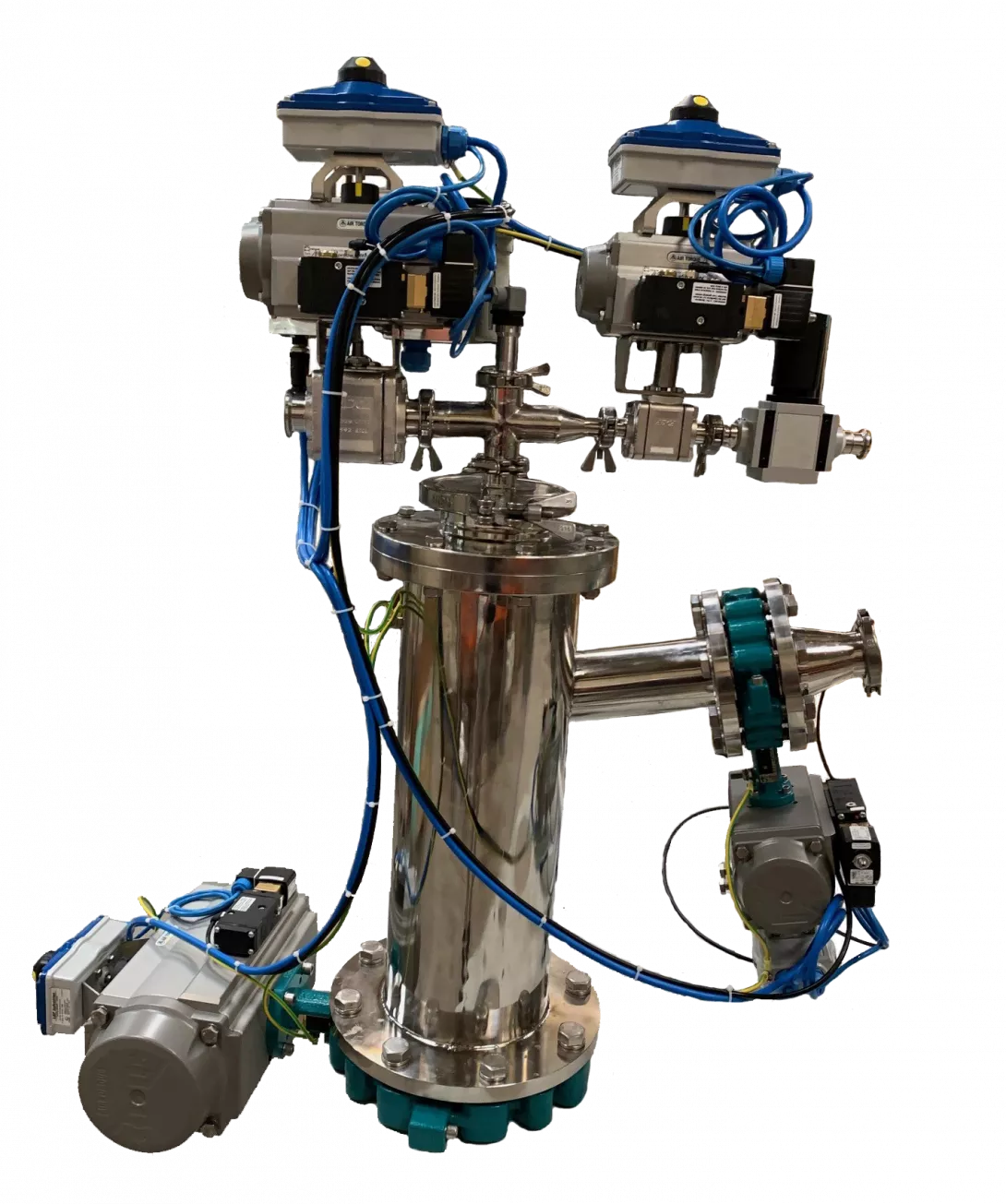

Reliable & Contained Powder Conveying

Transferring powders between process equipment can lead to dust formation, product loss, and operator exposure. Our Powder Pumps ensure a completely enclosed, dust-free transfer, reducing contamination risks and improving workplace safety. Designed for pressurized reactors, dryers, and Filter / Dryers, they offer a highly efficient and flexible powder handling solution for the pharmaceutical, chemical, and fine chemical industries.

Performance & Safety

Dust-free, enclosed powder transfer

Minimized attrition and product degradation

Compatible with CIP (Clean-In-Place) for easy cleaning

ATEX-certified for explosive environments

Safe, Controlled & Efficient Transfer

Our Powder Pumps use dense-phase flow technology to transfer powders without product segregation or excessive turbulence. This ensures a smooth, consistent flow, making them ideal for handling sensitive or hazardous powders. The fully enclosed system prevents dust exposure, keeping your operators and facility safe and compliant with regulatory standards.

Key Applications

Dust-free transfer of pharmaceutical powders

Closed-system material handling in API production

Powder transfer to reactors and dryers in fine chemicals

High-containment powder conveying in hazardous environments

Need a reliable, contained powder transfer solution?

Documents to Download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.