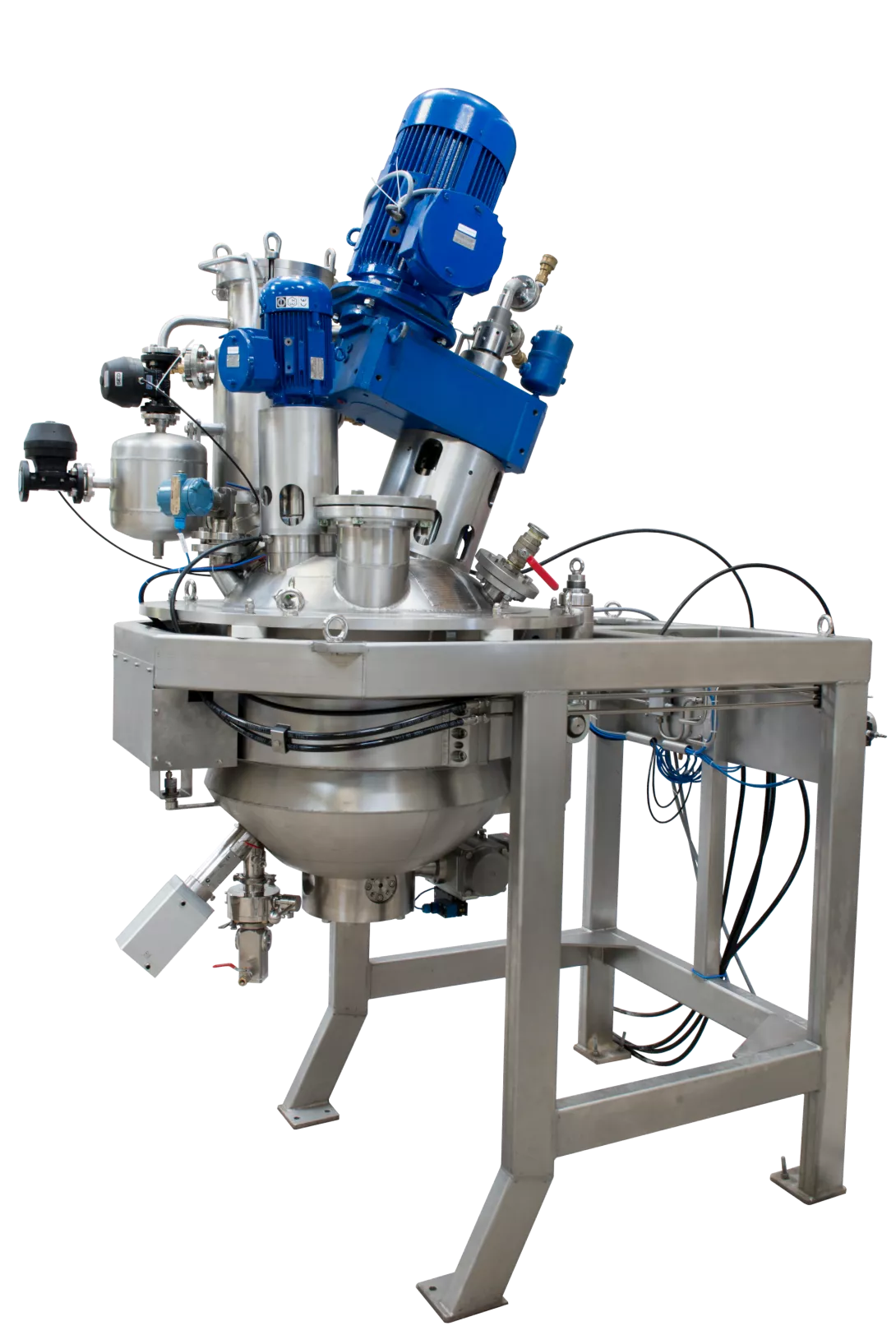

The most space saving drying solution

This spherical dryer is a versatile solution for drying, mixing and granulating.

The highest performance standard

Dedicated or multi-purpose applications : the best in product quality, total discharge, cGMP production, cleanability.

The spherical dryer is recommanded for both fast discharging and quick inspection by swivelling up the lower half of the sphere.

Advantages

Total product discharge

Most compact dryer

Fast and easy cleaning

Vertical chopper or lumpbreaker included

High mixing capability

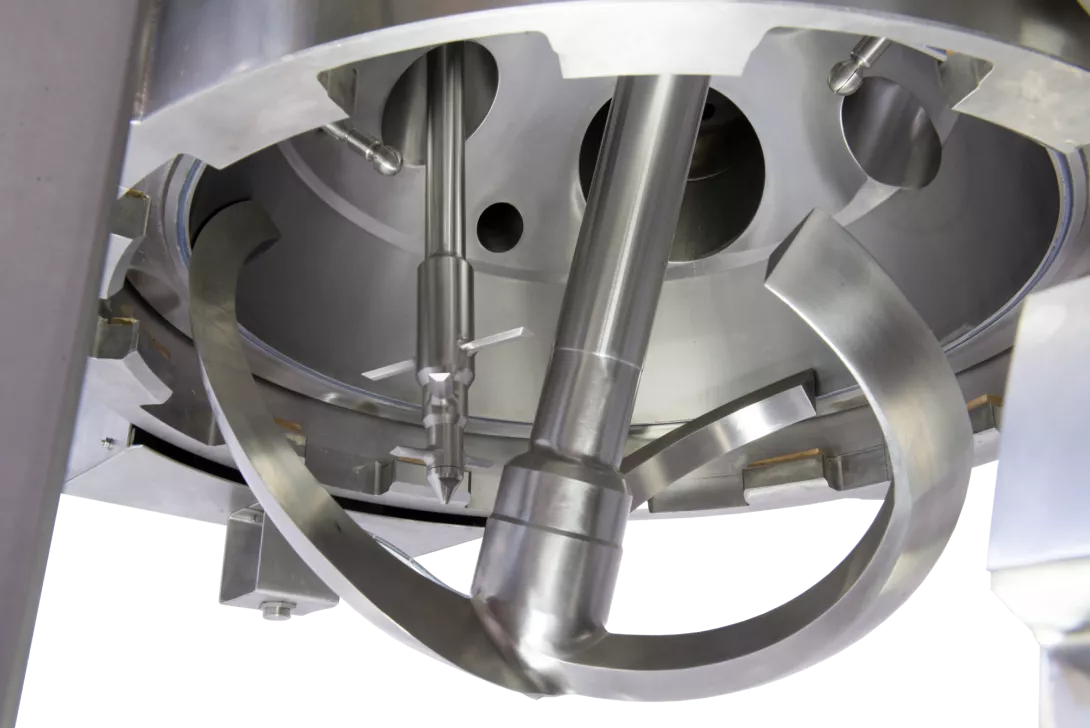

3-arm agitator

The three-arm agitator allows a high degree of mixing with a high speed.

The agitator is optionaaly heated to shorten drying times.

High speed chopper

The vertical chopper ensures reduces lump formation, while ensuring that no wet product is sprayed on parts of the walls that the agitator does not reach.

Drying results are consistent results whatever the filling volume.

Need more info?

Our teams are ready to help you!

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.