Precision-engineered reactors with advanced mixing technology

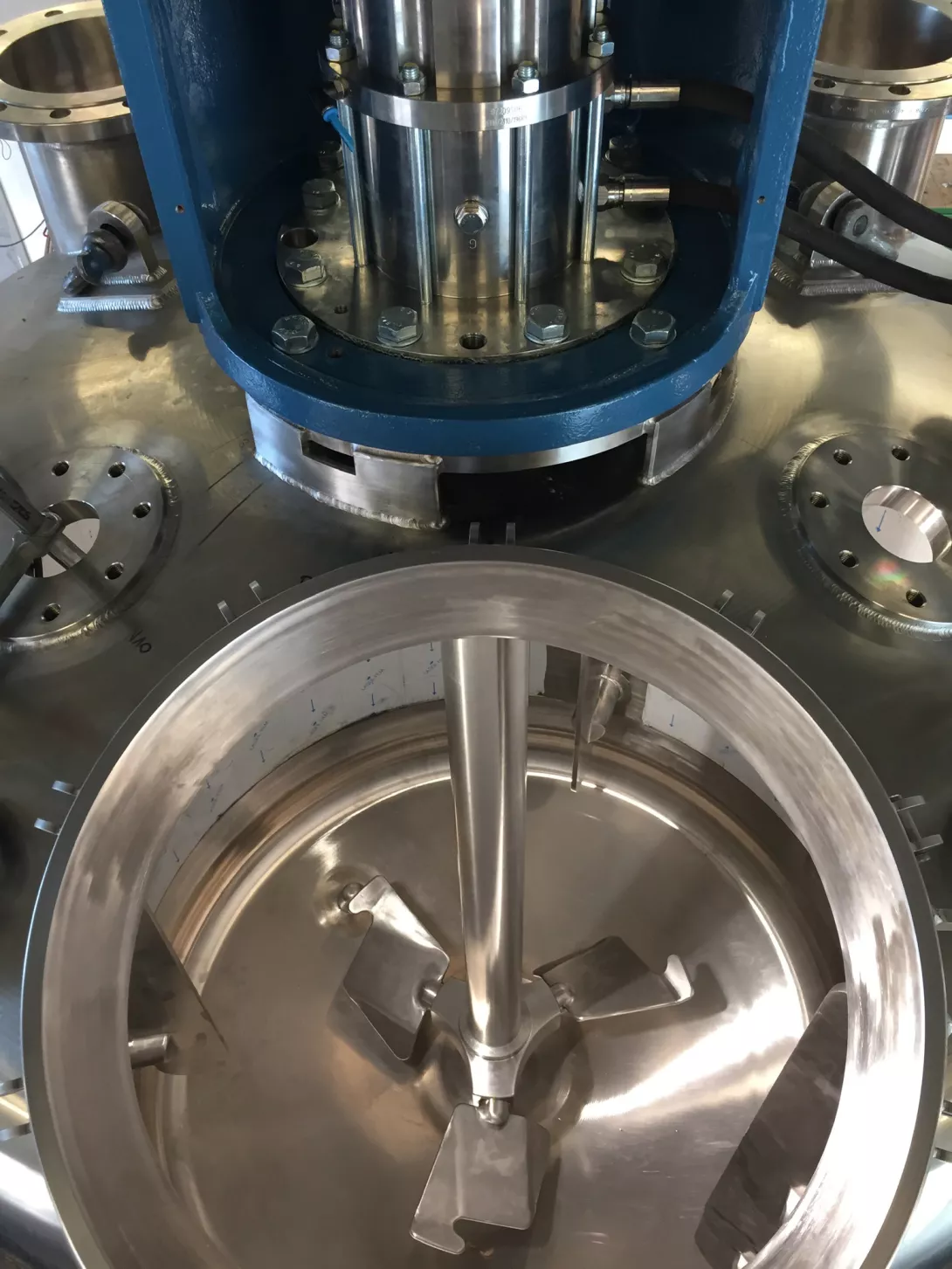

FlexTech reactors combine mechanical performance, process efficiency, and material durability for demanding chemical applications. Designed with high-grade stainless steel and alloys, they offer optimized mixing, heat transfer, and cleanability for multipurpose processes.

Available in 316L, 904L, C22, Duplex, and other specialized materials, these reactors provide exceptional resistance to corrosion, high pressure, and extreme temperatures.

Tailor your reactor to your exact needs.

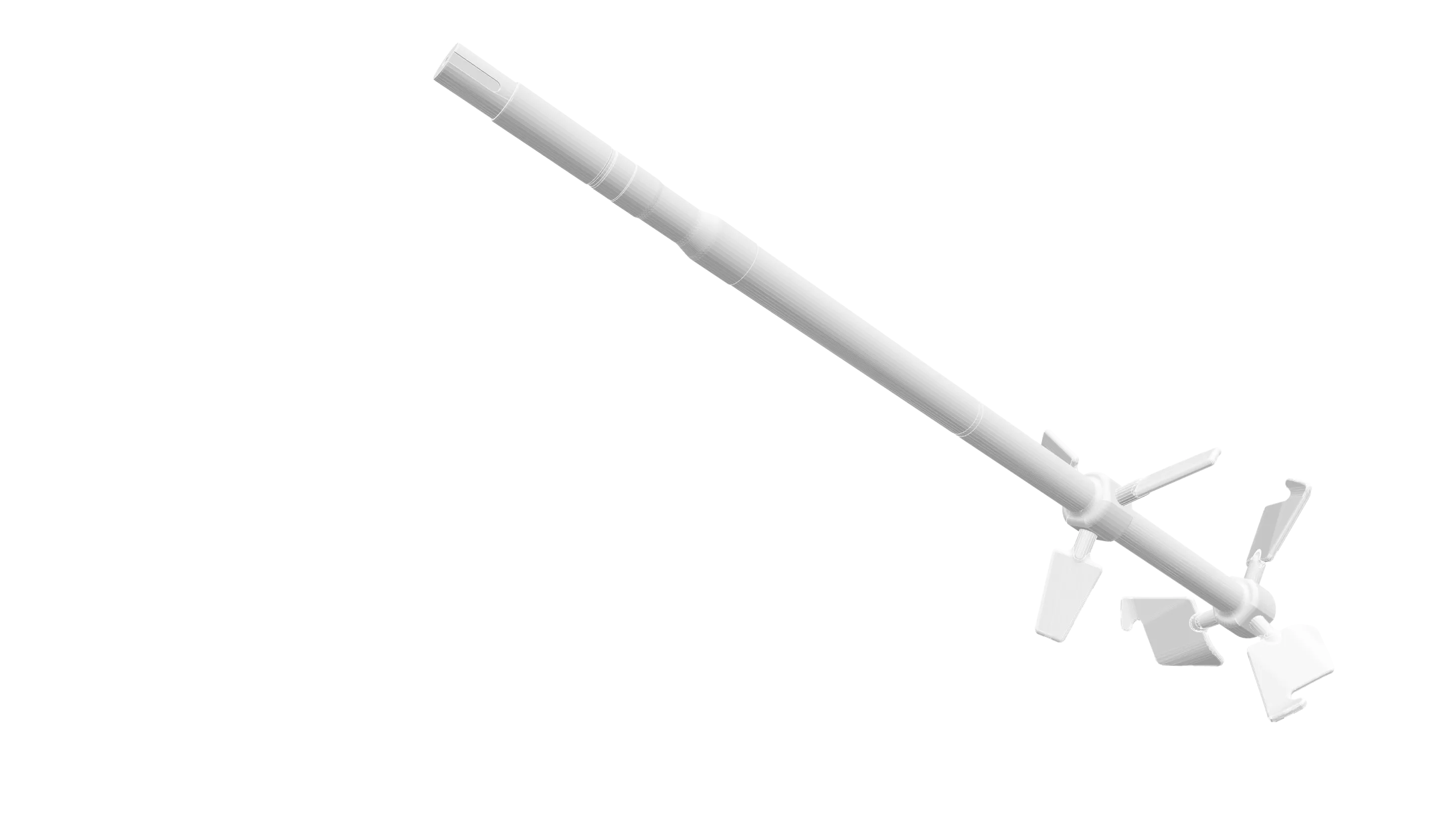

- Advanced agitation technology – Choose from OptiFoil®, HydroFoil®, Flat®, Trapezoidal®, ViscoFoil®, BreakerBar®, and more

- Custom surface finishes – Up to Ra <0.25 µm for enhanced cleanability and reduced contamination risk

- Versatile configurations – Single, double, or triple-stage agitators with normal or half-coil jackets

- Cryogenic compatibility – Insulation with Foamglas® cladding for processes down to -100°C (-148.00°F)

Performance & Safety

Process intensification – Efficient mixing and improved heat transfer

Integration of all mechanical aspects – Ensuring durability and long-term reliability

Global compliance – Certified for PED, ATEX, and Machinery Directives

Optimized cleaning solutions – Validated with CIP systems for full cleanability

FAT with dynamic testing – Ensuring quality before installation

Key Applications

Fine chemicals & pharmaceuticals – Precision mixing for high-purity production

Polymer & specialty materials – Homogeneous blending of high-viscosity compounds

Chemical process engineering – Efficient heat transfer for optimized reaction control

Cryogenic applications – Safe and efficient operation at ultra-low temperatures

Looking for high-performance stainless steel reactors?

Experts are available to discuss your process requirements.

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.