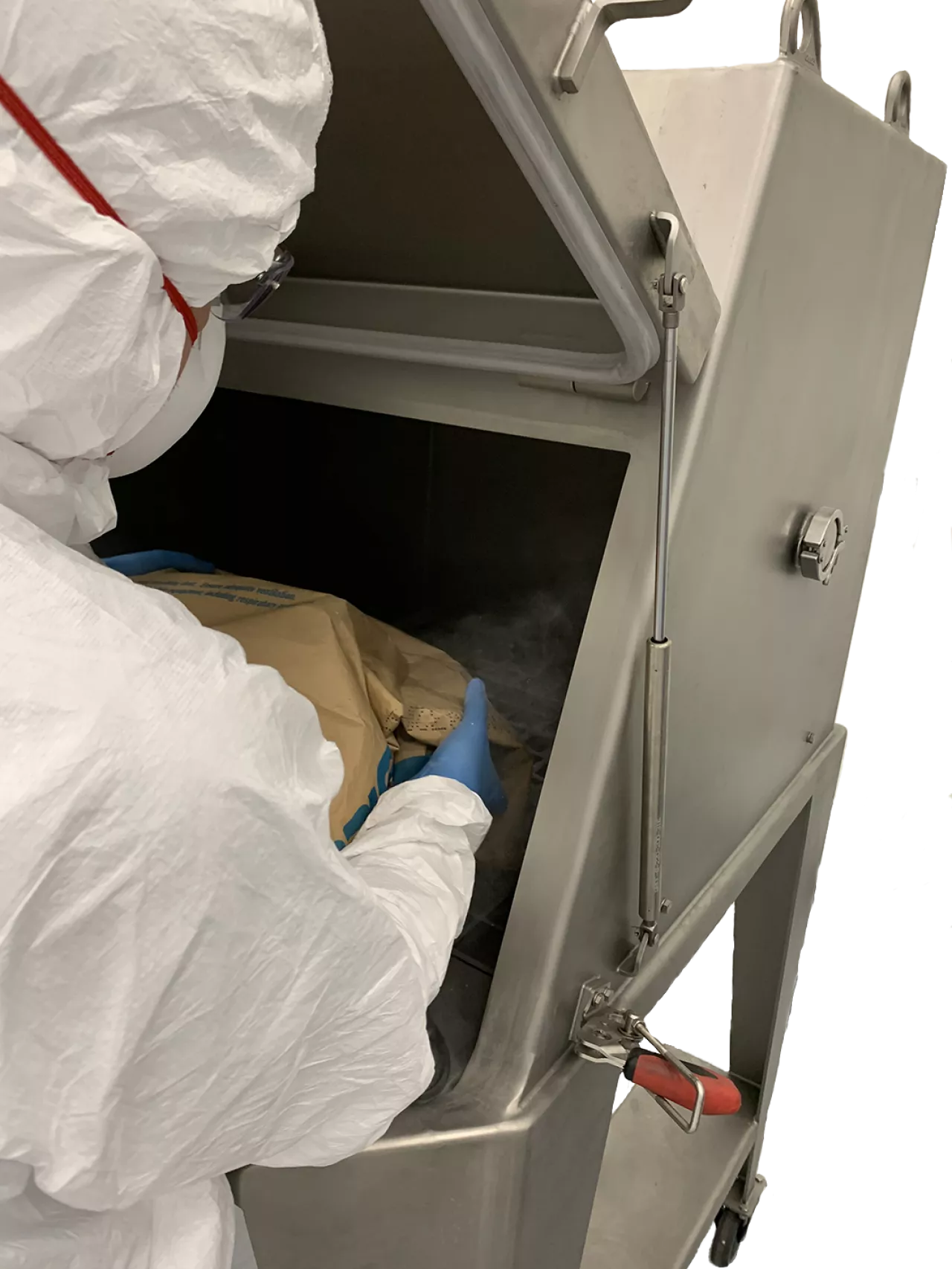

Rip & Tip Station

Dust-free manual bag emptying for safe powder handling

Controlled Bag Emptying with Minimal Dust

Manual bag emptying can generate dust emissions, product loss, and operator exposure. Our Rip & Tip Stations provide a fully enclosed, dust-free solution, ensuring a controlled and contamination-free powder transfer into process equipment such as reactors, storage vessels, or Powder Pumps. Designed for easy operation and seamless integration, they improve industrial hygiene, safety, and efficiency.

Performance & Safety

Ventilated enclosure with local or remote filter and fans to limit dust exposure

Delumper available

Cleaning-In-Place (CIP) as option

ATEX-certified for explosive environments

Reduce Dust & Improve Containment

Our Rip & Tip Stations minimize powder dispersion with integrated dust extraction and contamination control. The ergonomic design allows for manual bag handling with minimal effort, ensuring a safer, cleaner work environment and compliance with hygiene standards in pharmaceutical, chemical, and food industries.

Key Applications

Manual bag emptying with limited dust exposure

Comfortable emptying of 10-20 kgs bags

Safe transfer of raw materials into process vessels

Integration with vacuum transfer systems, see: Powder Pump

Looking for a safe and efficient manual bag emptying solution?

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.