Short Path Evaporator

The unique evaporator for extraordinary applications

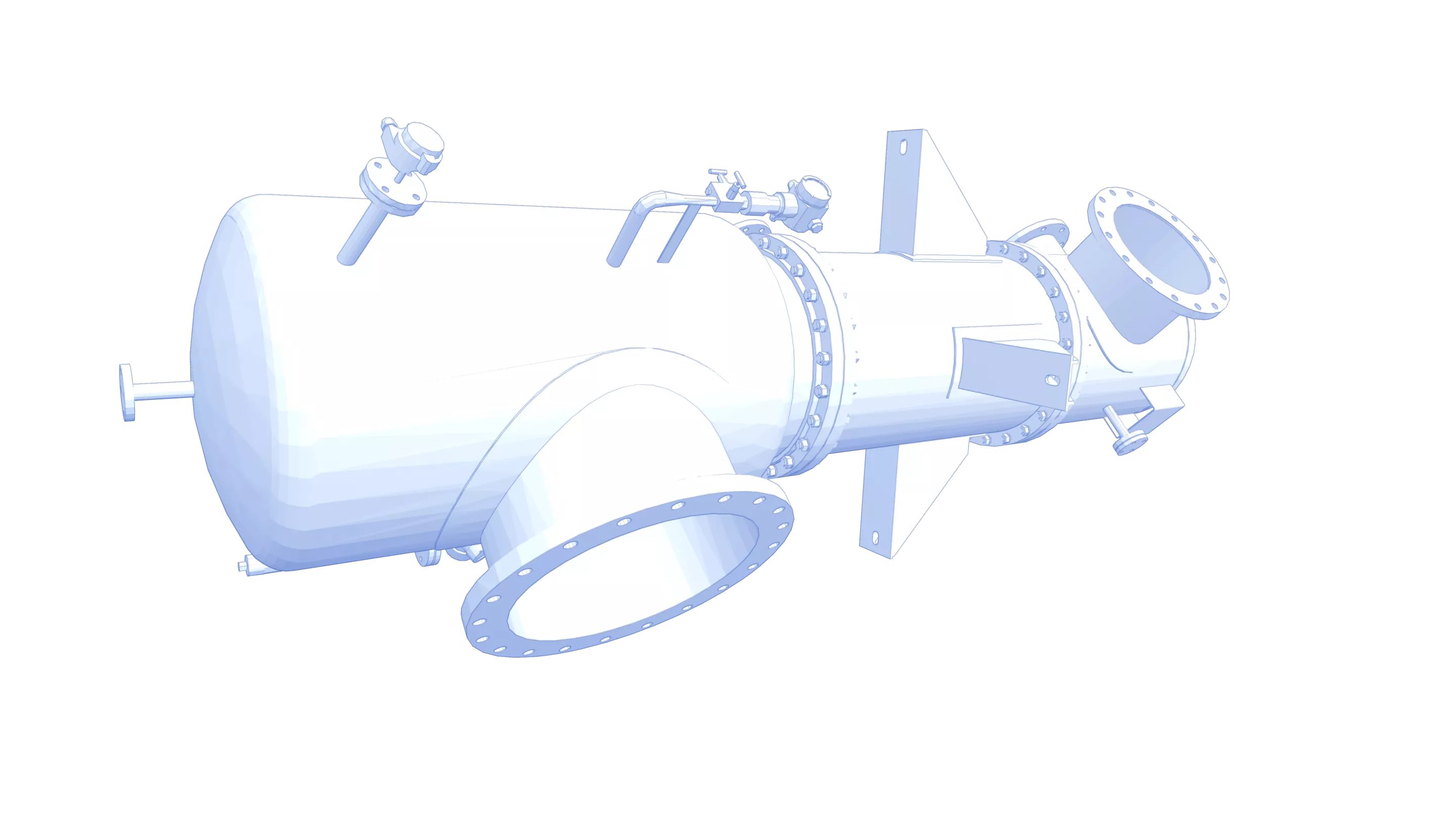

How It Works

When conventional evaporation techniques fall short, the Short Path Evaporator provides an exceptional solution for high-purity distillation. Operating under ultra-high vacuum (down to 0.001 mbar), it enables low-temperature separation, making it ideal for heat-sensitive and complex products. Designed for high separation efficiency, it ensures gentle processing and minimal thermal degradation, making it widely used in the pharmaceutical, food, and specialty chemical industries.

Performance & Safety

Vacuum distillation down to 0.001 mbar

Low-temperature processing for heat-sensitive compounds

Short residence time minimizes thermal stress

Internal condenser reduces pressure loss and maximizes efficiency

High-Purity Distillation Under Extreme Vacuum

The feed liquid forms a thin film inside the evaporator wall, distributed by a rotating system (rollers or wipers) that ensures optimal separation efficiency. The internal condenser minimizes pressure loss and maintains high vacuum conditions, ensuring efficient vapor condensation and product purity. The concentrated product exits at the bottom, while the distilled vapor is collected through the internal condenser for maximum recovery.

Key Applications

Purification of natural compounds (Squalene, Sterols, Vitamin E, Omega-3)

Odor and color improvement in chemical intermediates

Purification of mineral oils and waxes

Looking for a high-efficiency evaporator for heat-sensitive products?

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.