Glass-Lined Filter / Dryer

When equipment made of high quality steel or alloy C-22 do not satisfy the expectations anymore, the application of enamel coating is the ideal solution.

THE IDEAL SOLUTION

Some agents, intermediates, and extracts place demanding requirements on filtration/drying processes — whether due to corrosive effects on the environment or high sensitivity to metals, contamination, or temperature. At the same time, process efficiency and product quality must be maintained at every stage. In such cases, even equipment manufactured from C-22 alloy may no longer meet expectations. Applying enamel as a surface protection offers the ideal solution.

OPTIMAL COST/PERFORMANCE RATIO

Under the historic Rosenmund® brand, De Dietrich offers enamel-lined filter dryers designed for complex production processes. As a premium alternative to alloy equipment, these solutions deliver an excellent cost/performance ratio.

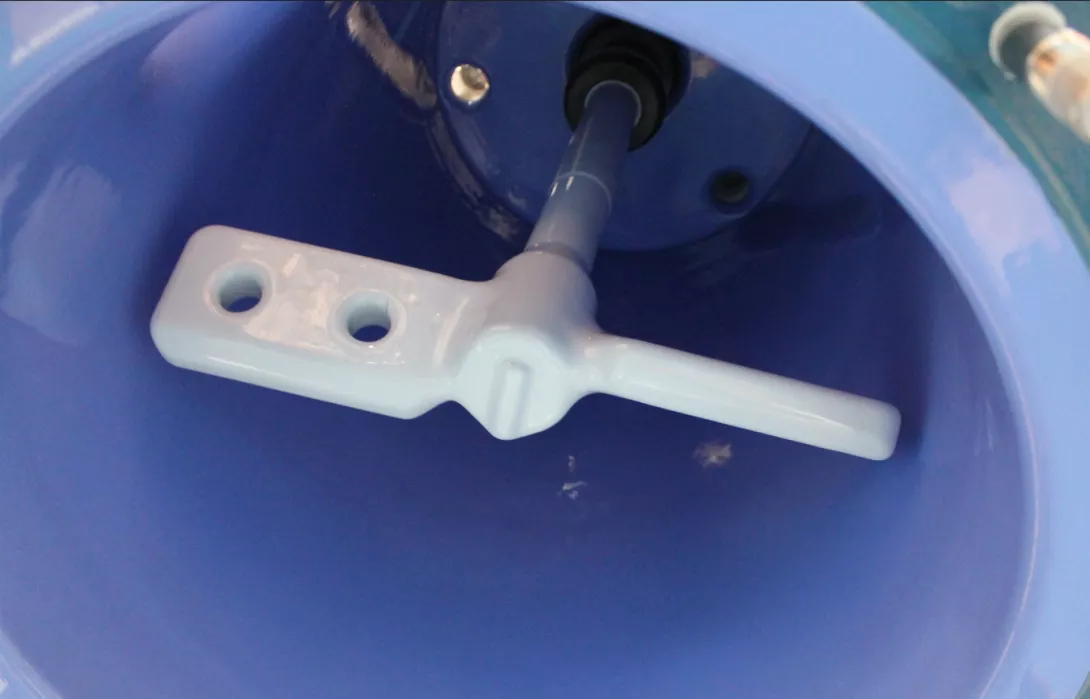

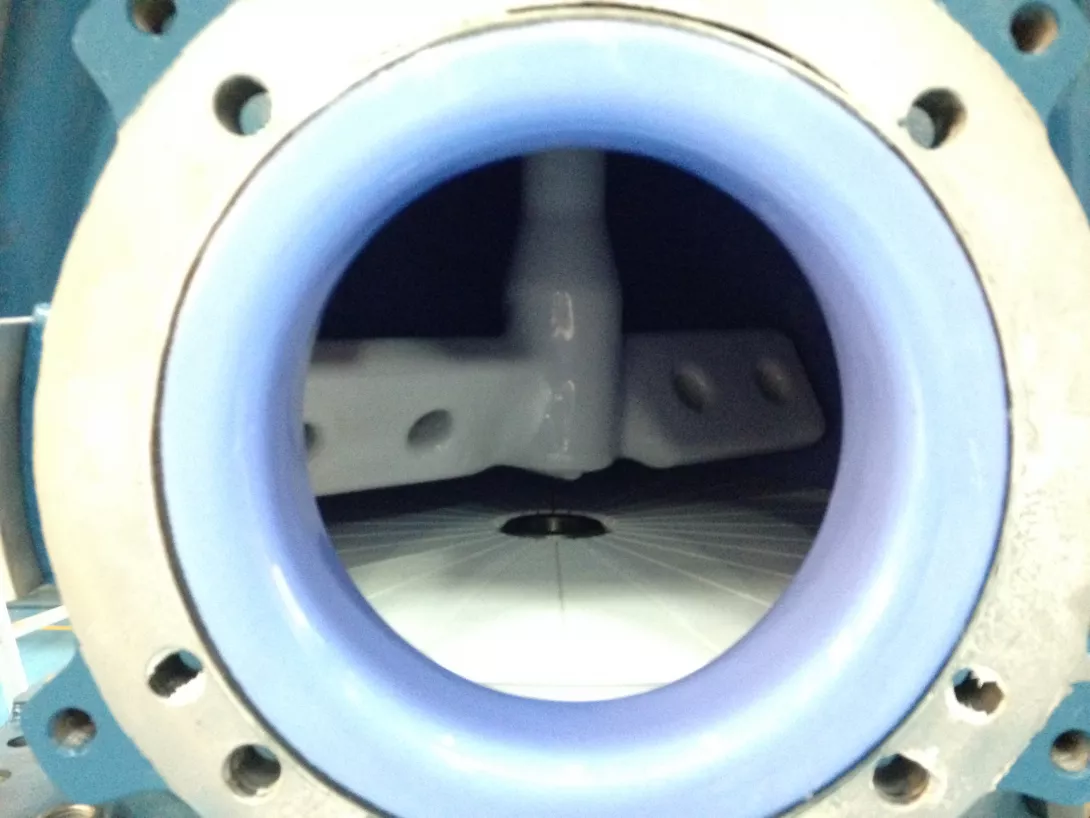

All product-contact surfaces and components are lined with our high-quality DD3009 enamel.

Exclusively manufactured by De Dietrich®, the DD3009 enamel stands out for its exceptional resistance to highly corrosive media and abrasion, while covering a broad range of operating temperatures and pressures. Its low surface roughness ensures easy cleaning and reduces the risk of cross-contamination.

Enamel-lined equipment offers outstanding value and represents an attractive alternative to C-22 alloy filter dryers. It enables efficient filtration and drying processes, along with fast product changeovers

Benefits of the Glass-lined Filter / Dryer

The Glass-Lined Filter / Dryer range provides the following benefits:

High constancy against highly corrosive medias and abrasion

Suitable for sensible products against metals, contamination or temperature

Large area of application due to operating temperature and pressure

Advantageous alternative to equipment in alloys C-22

Lower investment costs

High profitability

High flexibility regarding area of application

Reduce risks of cross contaminations

STANDARD OPTIONS

- Heated Rosenmund® S-blade agitator

- Sample valve

- Clean Seal for ideal discharge

- Gas Knife for complete discharge of the product

- Easy Clean for manual cleaning without stopping the containment

- WIP-device for efficient cleaning of the inner vessel and dust filter

- Different control options

- Containment-Systems

Need more info?

Our teams are ready to help you!

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.