Sistema de agitación GLASLOCK®

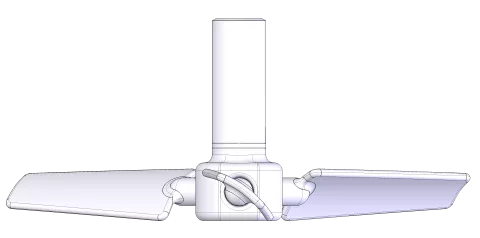

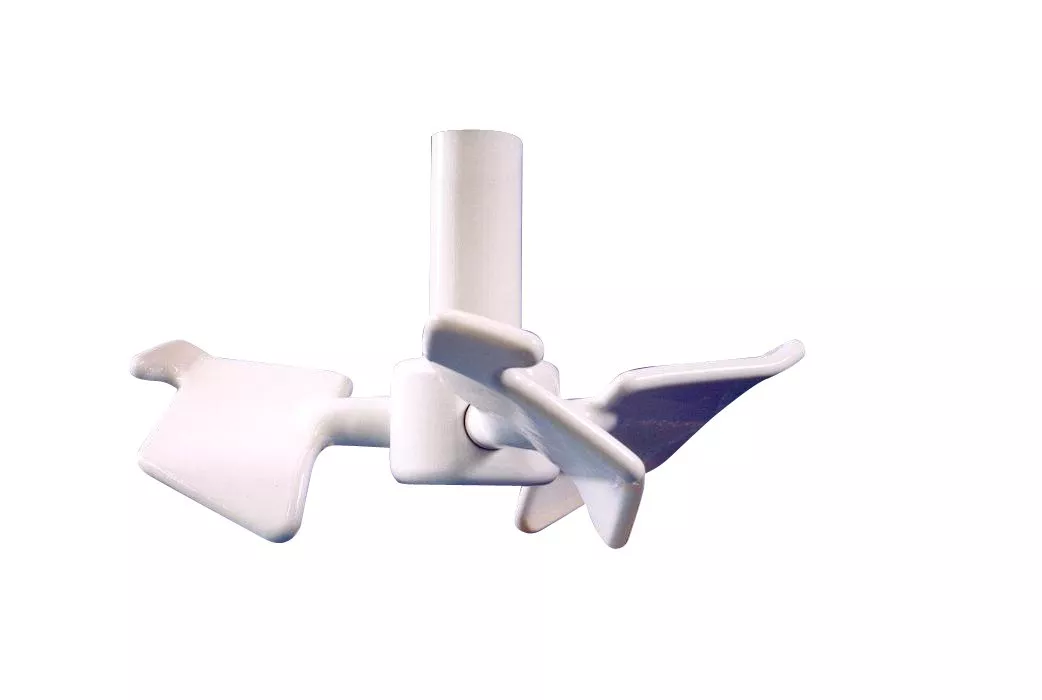

Exclusivo de De Dietrich, el sistema GlasLock es un agitador que le permite elegir entre varios perfiles de palas para optimizar su agitación. Somos capaces de realizar estudios para determinar el diseño que mejor se adapta a sus procesos y productos, garantizando resultados óptimos.

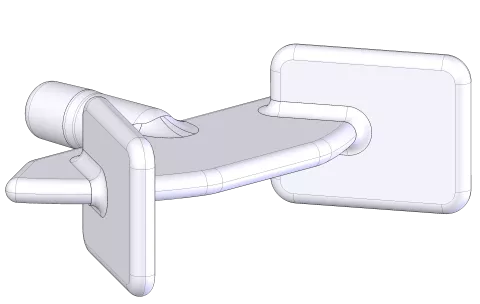

El único sistema en el mundo con palas removibles

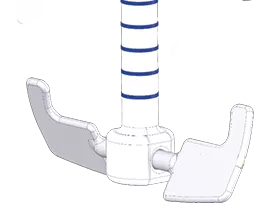

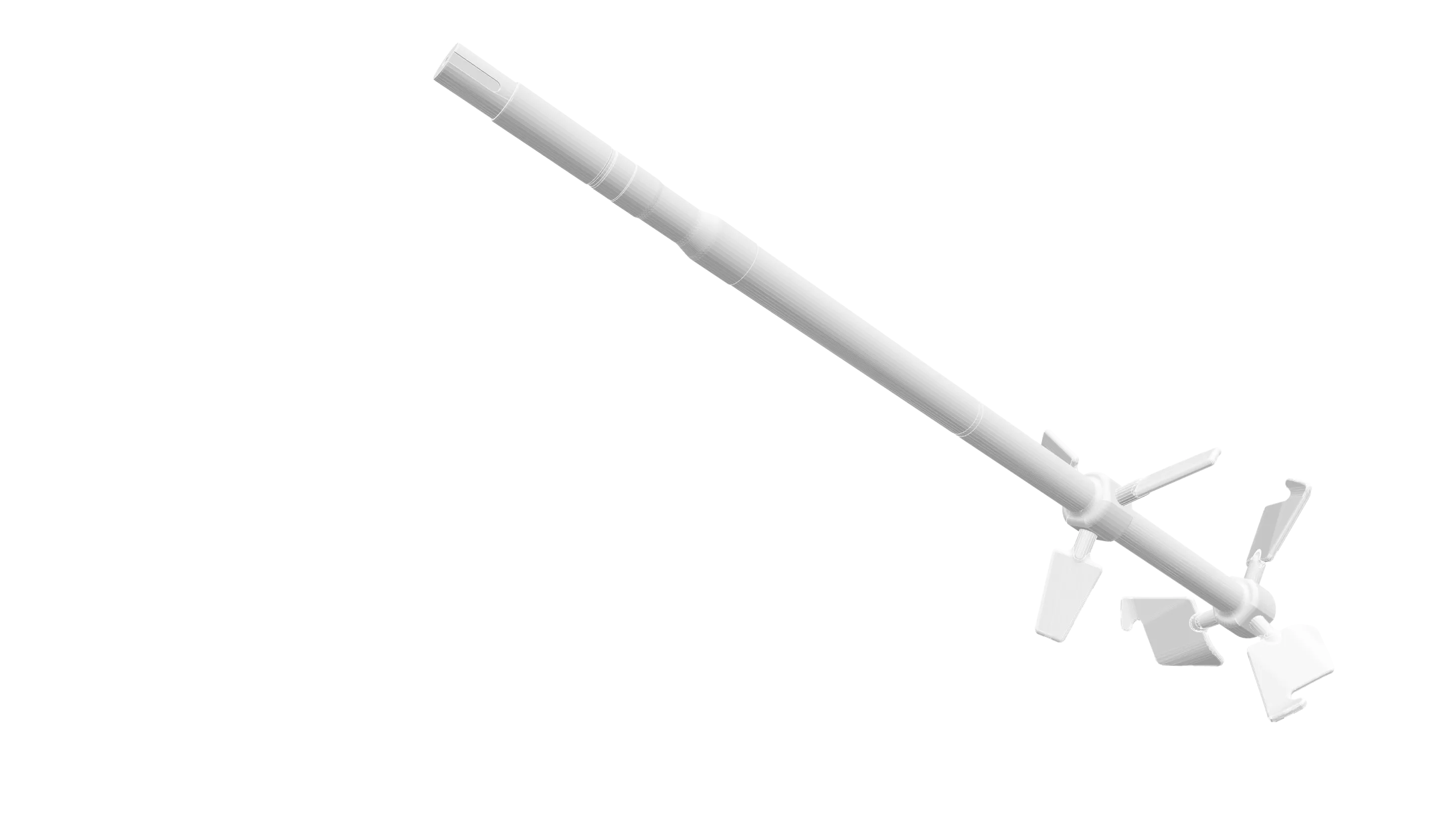

Este sistema ha sido diseñado especialmente para reactores BE, donde la apertura principal es la trampilla, pero es utilizable para todo tipo de reactores.

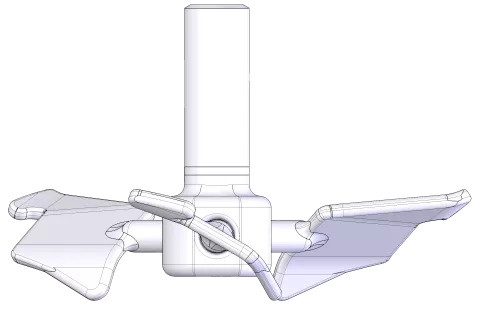

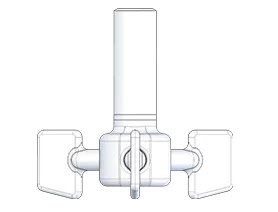

El montaje y desmontaje se realizan lateralmente, lo que permite trabajar en los agitadores sin necesidad de desmontarlos completamente.

Con agitadores de múltiples etapas, es posible modificar solo una etapa de manera independiente sin mover el agitador.

Fácil mantenimiento

El ensamblaje de una pala en su emplazamiento cónico, ambos completamente esmaltados, se realiza utilizando una herramienta manual según un procedimiento sencillo. GlasLock utiliza un solo buje que ofrece mayor flexibilidad al permitir la instalación de todo tipo de perfiles de palas. Esta tecnología reduce el tiempo necesario para desmontar el sistema de transmisión, cuando es necesario.

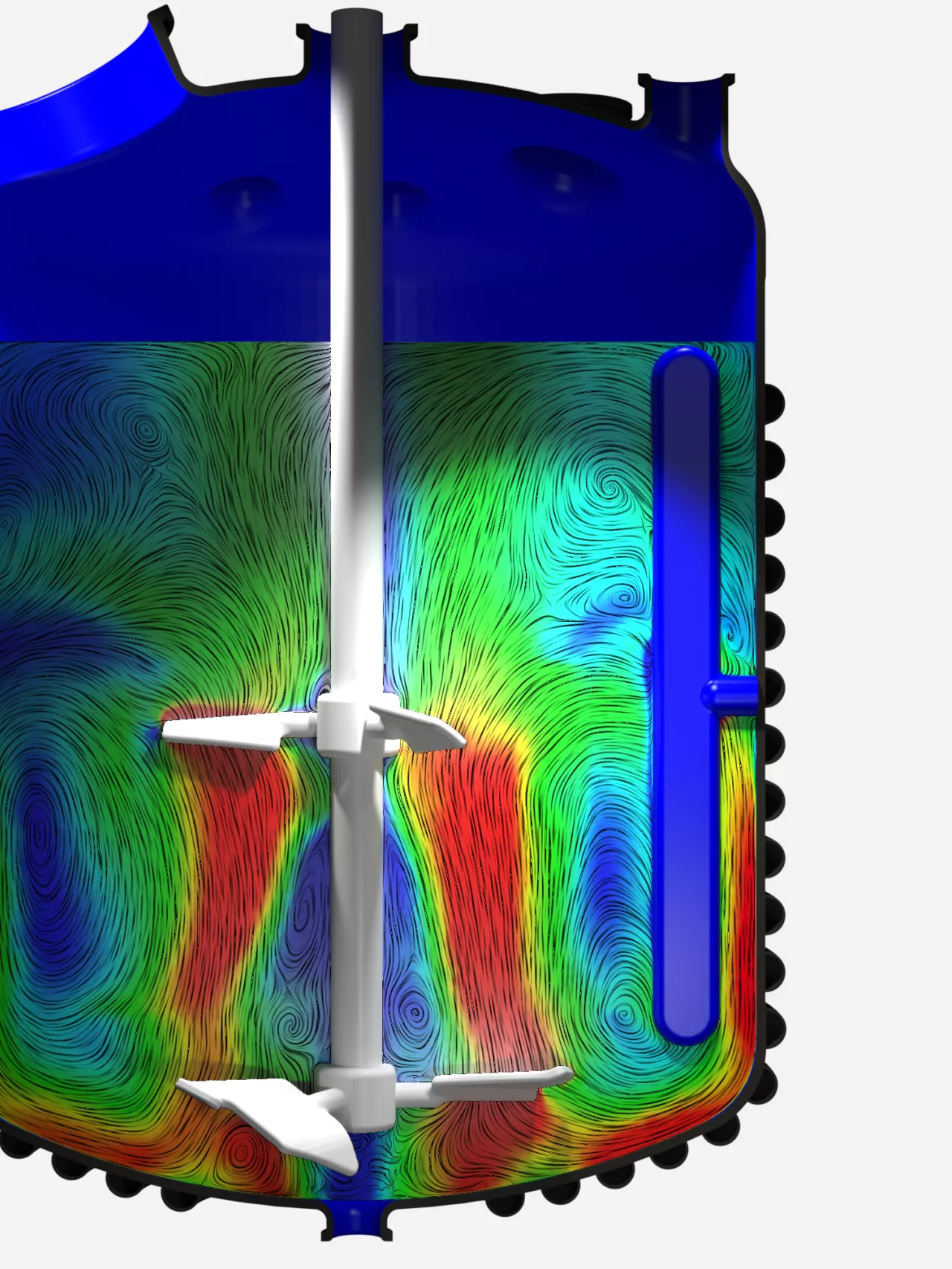

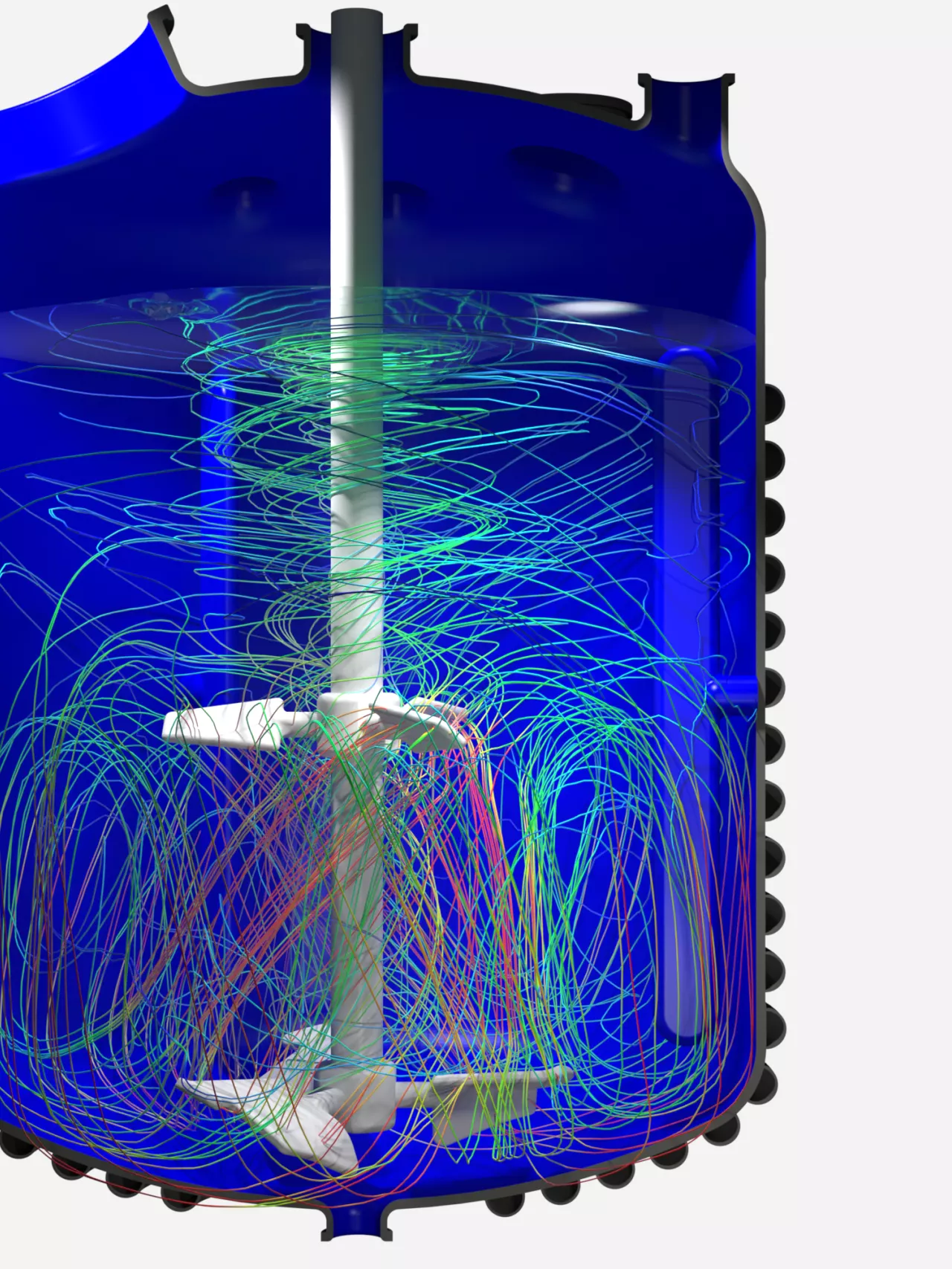

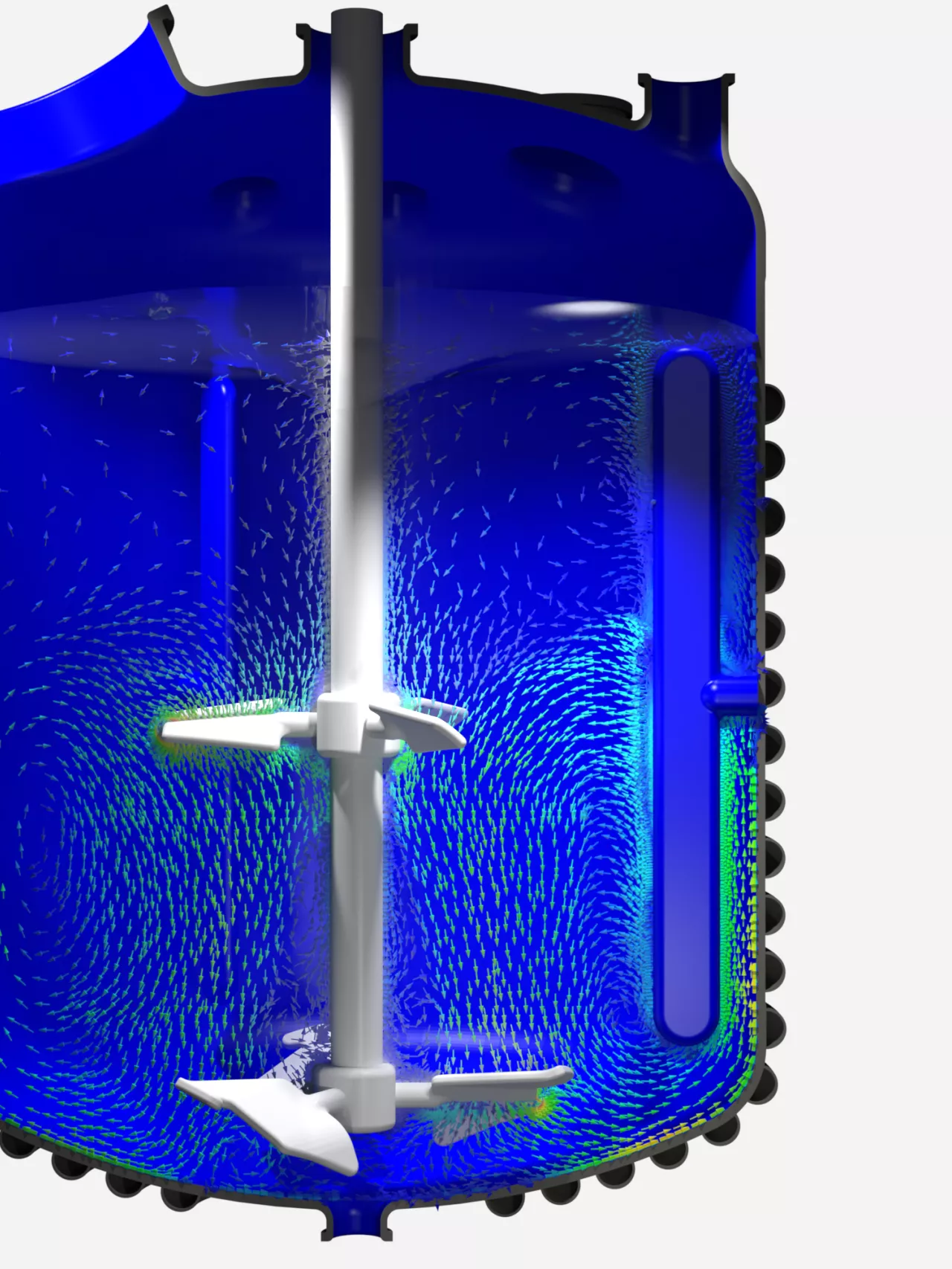

Para optimizar los resultados de sus reacciones, nuestro equipo puede realizar simulaciones personalizadas basadas en los parámetros de su proceso y las características de su producto.

Las ventajas del sistema GlasLock, combinadas con nuestros estudios, garantizan la mejor configuración de palas posible, reduciendo los tiempos de reacción, disminuyendo el consumo energético y optimizando su producción.

Mezcla optimizada y operaciones de mantenimiento

Mezcla mejorada a comparación con el agitador monobloque

Desmontaje individual de las palas y estandarización de repuestos

Volumen mínimo agitado de hasta el 1%, dependiendo de ciertos diseños de palas

Múltiples diseños de palas disponibles para optimizar y satisfacer las necesidades de sus procesos

Hasta 3 etapas en el agitador

Simulaciones y estudios para ayudarle a definir la mejor configuración

Experiencia en simulaciones y estudios

Hemos desarrollado nuestro propio software de mezcla y utilizamos software CFD para guiarle en sus decisiones.

Podemos ayudarle a definir las mejores configuraciones de palas para nuevos proyectos, y también podemos ayudar a optimizar y mejorar los procesos existentes.

Gracias a nuestra amplia gama de palas, podemos proponer las mejores soluciones para sus procesos.

¿Necesita ayuda?

If you would like a sales representative to contact you regarding De Dietrich products or services, please contact us hereSi desea que un representante de ventas se comunique con usted sobre los productos o servicios de De Dietrich, por favor contáctenos aquí.

Descargue el documento

Solicitar una descarga

Con el fin de procesar su solicitud de folleto de manera eficiente, le rogamos que nos facilite la información requerida a través de nuestro formulario.