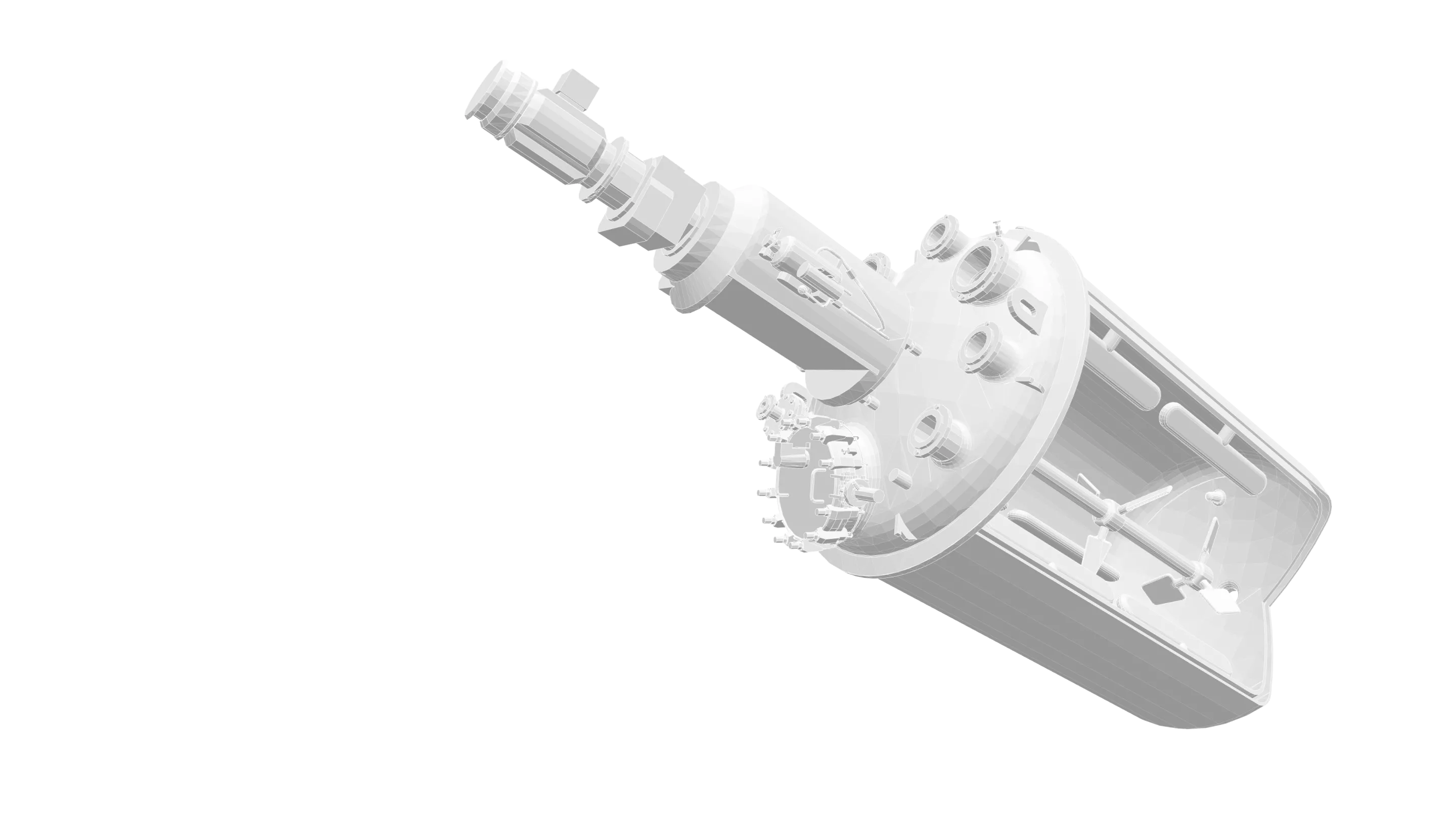

El Reactor Optimix

Exclusivo de De Dietrich Process Systems, el diseño del reactor OptiMix® ofrece una enorme optimización del rendimiento de mezcla mediante la integración de tres deflectores en la pared del recipiente y una sonda de temperatura en la parte inferior del recipiente. El diseño Optimix® puede aplicarse a todos los reactores de la gama DIN (AE, BE, CE).

OptiMix® reactor: The efficient technology

This patented design enhances heat transfer, solids suspension and distribution, gas dispersion, gas flow rates and mass transfer.

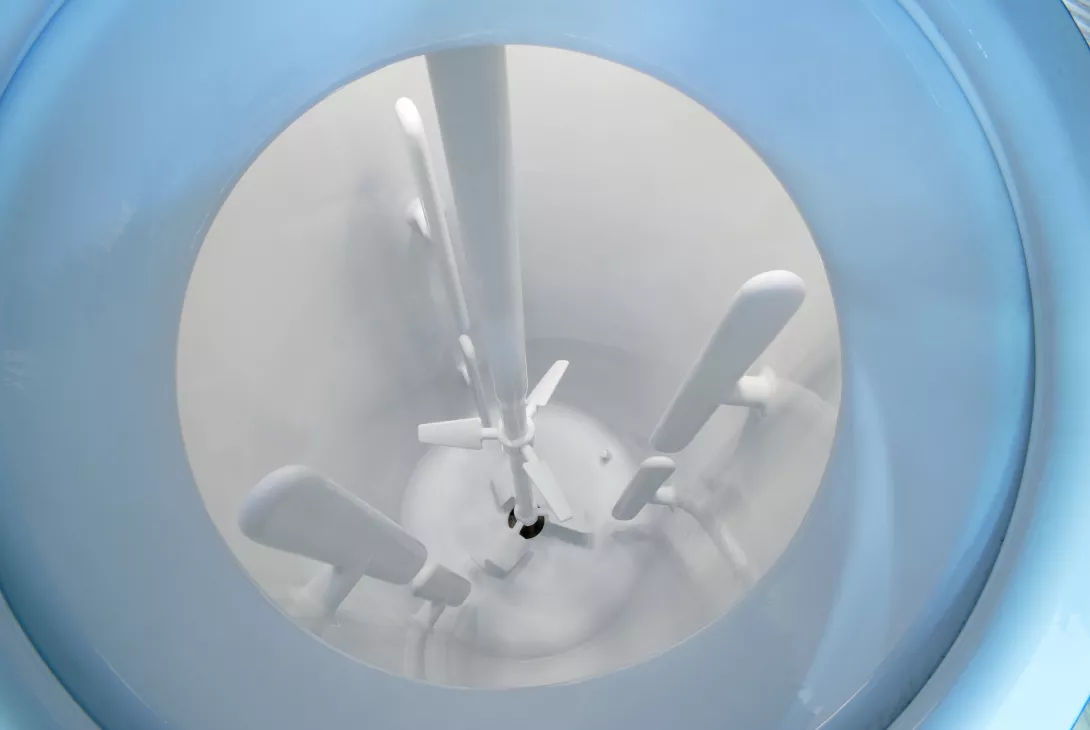

The OptiMix glass-lined reactor's performances are based on the integration of three baffles onto the vessel wall. This leads to a notable improvement in terms of mixing and heat transfer effeciency compared to standard reactors.

This specific design also frees up nozzles that can be used for your process or for the installation of options such as sampling devices, spray balls and much more.

The profile of the blades prevents the accumulation of crystals in the event of crystallization. This design satisfies two of industry's primary requirements: optimal process efficiency and improved cleanability of the reactor, as well as a reduction of the amount of dead zones which generally occurs with a standard, nozzle-mounted baffle.

Optimix is also available in an Optimix HE version (heat exchange), which improves heat exchange even further.

The polyvalence and reliability in every circumstances

OptiMix reactors are lined with DD3009 glass for superior corrosion resistance and easy cleaning.

They are also fitted with an integrated temperatur sensor in the bottom part which enables control of very small reaction volumes.

Components are interchangeable with standard reactors of the same size. OptiMix reactors can be equipped with jacket or half coil and are usually proposed with a GlasLock® agitator to improve mixing performances even further.

Polivalencia y fiabilidad en cualquier circunstancia

Los reactores OptiMix están revestidos de vidrio DD3009 para ofrecer una mayor resistencia a la corrosión. También están equipados con un sensor integrado en la carcasa que permite controlar volúmenes de reacción muy pequeños. El equipo es intercambiable con reactores estándar del mismo tamaño. OptiMix viene de serie con dos zonas de serpentín y un agitador GlasLock®, con camisa opcional.

Eficacia de la mezcla, para mejorar la transferencia de calor y de masa

Fácil de limpiar, sin salpicaduras ni productos flotantes.

Los deflectores están alejados de la pared: sin depósitos en las paredes, sin tensiones de dilatación en los deflectores, sin limitación de la pendiente de calefacción/refrigeración.

No más vórtices y menos residuos

Optimix® - HE (Heat Exchange)

Increase your heat exchange surface with the new generation of OptiMix - HE reactors

This new design uses the thermal fluid contained in the half-coil in order to create a circulation through the baffles.

As a result, film coefficients and heat transfer rates are higher than in conventional jackets.

By combining the advantages of the OptiMix’s three integrated wall baffles, we can now offer a high performance glass-lined reactor.

This results in an increased heat transfer performance up to 25%

You have questions?

Our teams are ready to collaborate with you and provide solutions for your projects

Documentos para descargar

Solicitar una descarga

Con el fin de procesar su solicitud de folleto de manera eficiente, le rogamos que nos facilite la información requerida a través de nuestro formulario.