BASE DE ACOPLAMIENTO DE BIDONES DE ALMACENAMIENTO

Transferencia segura y contenida de polvos

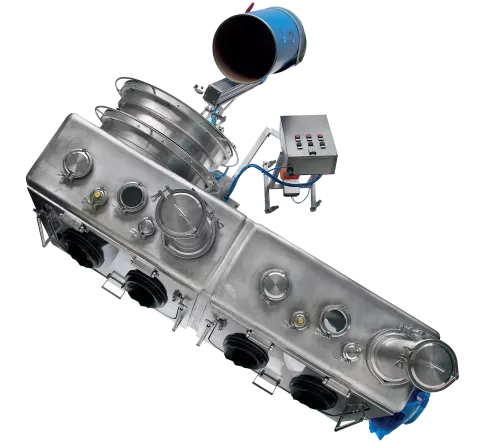

Reliable & High-Containment Drum Discharge

Charging reactors and process equipment from drums presents contamination and safety risks, particularly when handling toxic or hazardous powders.

Our Drum Dock Stations, equipped with DIT® (Double Iris Technology), ensure high-containment, dust-free discharge with precise control and minimal operator exposure. Seamlessly integrating with Powder Pumps, reactors, and other systems, they improve workflow efficiency and safety compliance.

Performance & Safety

DIT® technology for high-containment drum emptying

Handles multiple drum sizes with wide opening (up to 700 mm)

OEB 5 containment for highly potent powders

ATEX-rated materials for explosion-risk environments

Dust-Free, Controlled Powder Transfer

Our Drum Dock Stations eliminate powder dispersion by providing a fully enclosed, high-containment solution. The double iris valve system ensures a secure and repeatable process, making it ideal for pharmaceutical and chemical applications requiring strict containment and hygiene standards.

Key applications

High-containment drum emptying in API production

Safe powder discharge for highly potent compounds

Explosive powder handling under controlled conditions

Contained raw material loading for chemical reactors

Ensure safe, contained powder transfer with De Dietrich.

Solicitar una descarga

Con el fin de procesar su solicitud de folleto de manera eficiente, le rogamos que nos facilite la información requerida a través de nuestro formulario.