Reactores de vidrio

Observación perfecta del proceso

Uso universal y fácil limpieza

De Dietrich diseña y construye equipos e instalaciones para todo el ámbito de la ingeniería de procesos de reacción y separación térmica. Gracias a la experiencia adquirida a lo largo de los años, De Dietrich posee un conocimiento profundo en el tratamiento de medios altamente agresivos y de alta pureza. Los reactores de vidrio transmiten este know-how al usuario. Las soluciones presentadas incluyen equipos completamente desarrollados y estandarizados, así como equipos específicamente adaptados a cada proceso.

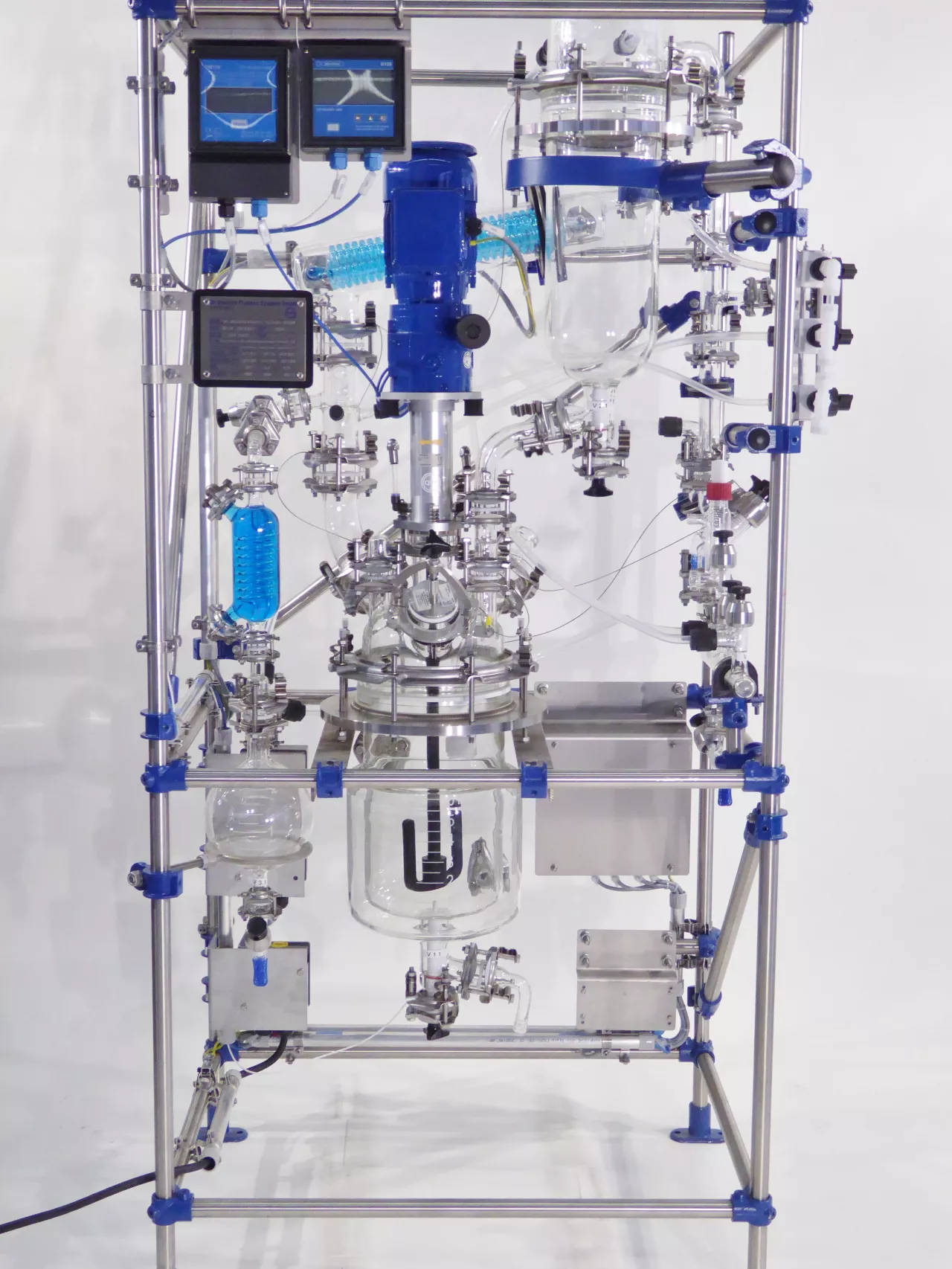

Reactor Universal QVF

Disponibles en varios tamaños, por ejemplo, reactores universales QVF de 50 L y 6 L.

Las plantas de vidrio de De Dietrich se distinguen por su alta fiabilidad operativa y sus costos de mantenimiento mínimos. Nuestro sistema de construcción modular y flexible, basado en componentes estandarizados de vidrio borosilicato 3.3, permite ofrecer soluciones tanto personalizadas como estandarizadas.

Combinando el vidrio con otros materiales resistentes a la corrosión, como el acero vitrificado, el PTFE, el PFA o el SiC, es posible realizar instalaciones económicas y fiables. El sistema de bridas QVF® SUPRA-Line garantiza una seguridad adicional y un funcionamiento sin necesidad de mantenimiento. Cada instalación puede modificarse o desmontarse fácilmente en caso necesario, y todos los componentes pueden reutilizarse sin problema.

Además, el vidrio como material ofrece múltiples ventajas:

- Resistencia universal a la corrosión

- Superficie lisa y no porosa que reduce los depósitos y las incrustaciones

- Inercia catalítica: las reacciones no se ven influenciadas por el material

- Seguro desde el punto de vista fisiológico y ecológico (reciclable al 100%)

- Estabilidad al vacío

- Transparencia que permite el control visual del proceso

- Vaciado completo

- Diseño modular, fácilmente modificable

Reactores de vidrio, elemento central de una planta de síntesis

Existe una gran variedad de recipientes de reacción de vidrio disponibles, en función del tipo de calentamiento requerido. Los reactores de vidrio con doble envolvente, de hasta 100 L, y los reactores equipados con resistencias de inmersión, de hasta 200 L, pueden calentarse y enfriarse mediante un fluido térmico. En cambio, los reactores esféricos de hasta 500 L, equipados con una manta calefactora eléctrica, solo permiten el calentamiento.

Para un control fiable de la reacción, la agitación eficiente y una transferencia de calor reproducible son tan esenciales como garantizar la estanqueidad frente a la atmósfera. Como estos requisitos dependen del proceso a realizar, De Dietrich ofrece distintos tipos de agitadores y motorizaciones industriales adaptados a cada necesidad.

El sistema de deflectores Optimix® ofrece una ventaja especialmente significativa: los deflectores están fijados en el interior del reactor, lo que mejora considerablemente la mezcla sin ocupar el espacio destinado a los deflectores estándar montados en la tapa del reactor. El sistema de deflectores Optimix® está disponible para todos los reactores de vidrio cilíndricos a partir de DN200. Al ser del mismo tipo que el utilizado en los reactores de acero vitrificado, este sistema facilita la ampliación de escala desde reactores piloto de vidrio hasta grandes reactores de producción en acero vitrificado.

Equipos auxiliares y diseño modular

Los reactores de vidrio se equipan según la aplicación con elementos adicionales de vidrio como depósitos de alimentación y de producto, columnas de destilación y condensadores, así como la instrumentación necesaria.

Siempre que es posible, estos equipos se ensamblan a partir de componentes estandarizados, lo que permite modificarlos fácilmente y adaptarlos a cualquier necesidad. Además, el uso de componentes estándar disponibles en stock ofrece la ventaja de una rápida disponibilidad.

Según el tamaño de los sistemas de reacción, estos se suministran preinstalados en su estructura de soporte como un sistema modular, listo para ser conectado a las utilidades necesarias.

REACTORES EN ATMÓSFERAS EXPLOSIVAS

De Dietrich le ofrece soluciones seguras para evitar cualquier carga electrostática posible mediante:

Ecualización de potencial fiable y de fácil instalación en todas las conexiones de bridas

Revestimiento disipativo de vidrio patentado

Componentes de PTFE disipativo conformes con las normativas FDA 21 CFR 177 y 178

Equipos con certificación ATEX y datos de fabricación fiables conforme a la norma CLC/TR 50404.

¿Tiene preguntas?

Como socio competente en sistemas de reacción avanzados, estaremos encantados de asistirle en la búsqueda de la mejor solución para sus síntesis.

Descargue el documento

Solicitar una descarga

Con el fin de procesar su solicitud de folleto de manera eficiente, le rogamos que nos facilite la información requerida a través de nuestro formulario.