The clear solution

The detailed knowledge about the borosilicate glass in combination with the engineering competences developed together with our partners throught recent decades enable us to provide state-of-the-art systems for reaction and thermal separation processes including distillation, extraction, absorption and filtration.

Sistemas de vidrio Cifras clave

Bioreactor

Increase your cell culture yields with this brand new range of reactors developed with users. From 5 to 20 liters.

GMP Reactor

- Borosilicate 3.3 Glass according EN1595 with or without jacket

- Monobloc inner vessel, ≤ Ra 0.02 μm

- Customized design (Optimization of the KLa)

AGITATION

- Minimization of agitation restrictions (CFD)

- Mechanical or magnetic

COVER & ACCESSORIES

- Stainless steel 316 L or Alloy

- Ferrite content < 5%

- Electro polished finish Ra < 0.5 μm

- EPDM gaskets with FDA, USP certificates

SERVICES

- QA / QC plan

- FAT, SAT

- Qualification : DQ, IQ, OQ

- Aftersales and spare parts

DOCUMENTATION

- According to GMP requirement

CONTROL / SUPERVISION

- Entry level with variable speed control

- 21 CFR part11 Control interface (on request) pH, RedOx, T°, aeration (KLa), stirring speed

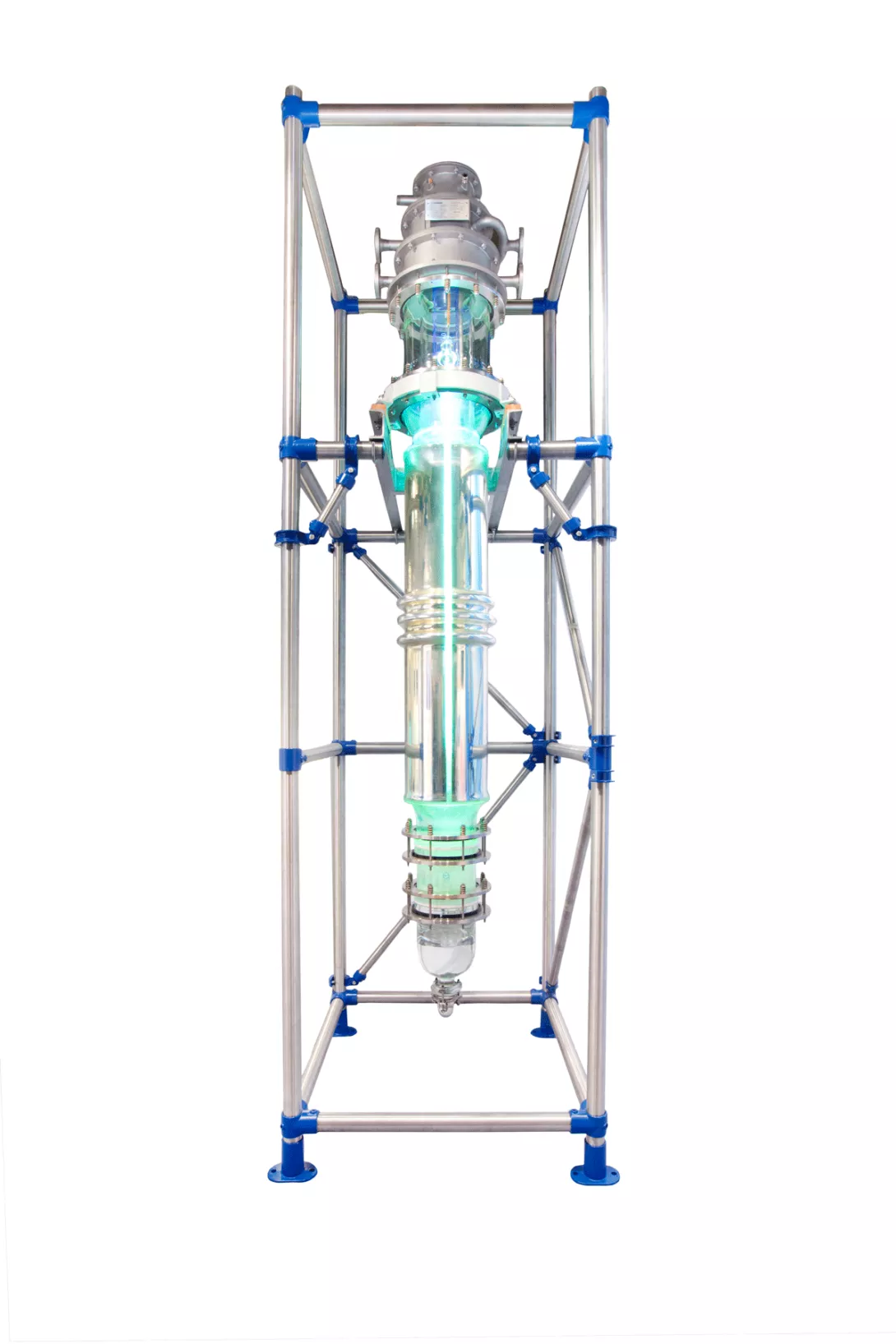

PhotoFlowReactor

The amount of photons required for a photochemical reaction is stochiometric means proportional to the quantity of starting material reached by the radiation. Additional photons are required to compensate the loss due to the absorption while passing through the material of the lamp, the of reactor and fluids as e.g. the solvent. With flow reactors the pathway of the radiation through the fluid can be kept short and hence the absorption low so that they are more efficient than stirred reactors. The PhotoFlowReactor consists of a cylindrical immersion lamp installed in a cylindrical pipe generating an annular gap. The reaction fluid flows through this annular gap, a short pathway for the radiation. This basic design is common in lab scale. De Dietrich Process System has transferred this concept together with PESCHL Ultraviolet GmbH into this production scale PhotoFlowReactor.

The PhotoFlowReactor is a flow reactor for photochemical reactions in a liquid phase with the option to disperse a reaction gas at the inlet. The photoreactions can be carried out between -30 to +100°C at up to + 1 barg. The max. hydraulic flow rate is far above 20m³/h so that the maximum operational flow rate is determined by the min. residence time necessary for the reaction. The PhotoFlowReactor has been standardized for different directly illuminated reactor volumes up to 150l.

A continuous PhotoFlowReactor permits a much narrower residence time distribution than a continuous stirred reactor so that a higher selectivity can be realized.

PhotoFlowReactors can be connected in series to increase the residence time or in parallel to increase the throughput. As such they can be operated in full continuous mode or in batch mode as side loop reactors.

Compact Gas Scrubber

The highly corrosion resistant compact gas scrubber is especially advantageous for batch wise operated production plants with waste gas streams up to 200Nm³/h at atmospheric pressure.

Filled with a suitable absorption liquid it is suitable for gas streams containing acidic or caustic and also organic loads. The absorption heat can be withdrawn by a heat exchanger. The unit is therefore of universal usage.

The column of the gas scrubber with an effective height of 2m is split into 2 sections so that the total height of the complete system is also only 2m. The mobile unit requires therefore only a minimum room height and clearance to get it transferred in one piece to its operational location.

It must only be connected to the electrical power and cooling water supplies.

The turn-key unit incl. control panel is ready for operation in ex-rated areas. The measuring and control equipment indicate the process parameters and alarms, run the plant always into a safe state and permit hence the unattended operation.

You have question?

Our teams are ready to collaborate with you and provide solutions for your projects

Documentos para descargar

Solicitar una descarga

Con el fin de procesar su solicitud de folleto de manera eficiente, le rogamos que nos facilite la información requerida a través de nuestro formulario.