Hautement résistant à la corrosion & lisse, non-poreux

Composants en verre QVF®.

Verre universel de qualité optimale pour toutes les applications.

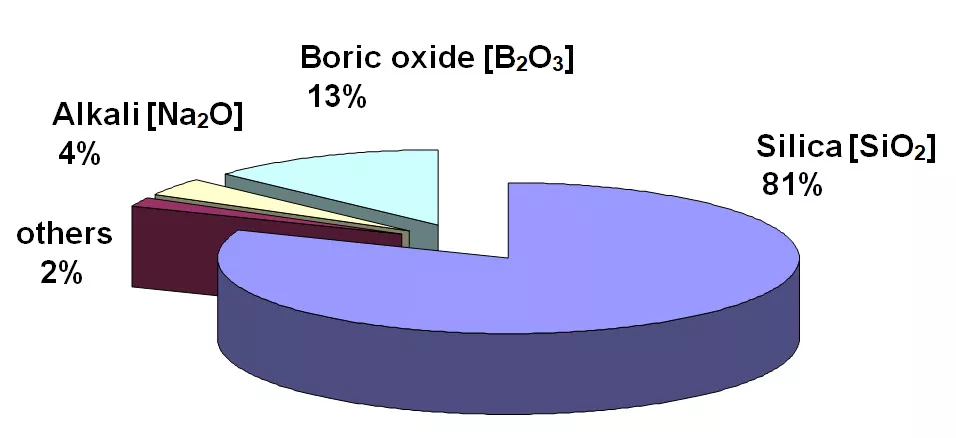

COMPOSITION CHIMIQUE

Les propriétés spéciales – particulièrement sa haute résistance aux produits chimiques, sa résistance à la température et son faible coefficient d'expansion linéaire – du verre borosilicate 3.3 utilisé exclusivement pour les composants en verre QVF® pour la construction d'unités en verre et de pipelines sont obtenues par un respect strict de sa composition chimique, qui est la suivante :

Chemical Resistance

A multipurpose glass with optimum quality, for all products

Borosilicate glass 3.3 is resistant to chemical attack by almost any product, which makes its resistance much more comprehensive than that of other well-known materials. It is highly resistant to deionized water, saline solutions, organic substances, halogens such as chlorine and bromine and most acids. There are only a few chemicals which can cause noticeable corrosion of the glass surface namely hydrofluoric acid, concentrated phosphoric acid and strong caustic solutions at elevated temperatures. However, at ambient temperatures caustic solutions up to 30% concentration can be handled by borosilicate glass without difficulty.

Borosilicate glass 3.3 can be classified in accordance with the relevant test methods as follows (see also ISO 3585 and EN 1595):

- Hydrolytic resistance at 98 ºC -Hydrolytic resist. grain class ISO 719-HGB 1

- Hydrolytic resistance at 121ºC - Hydrolytic resist. grain class ISO 720-HGA 1

- Acid resistance - Deposit of Na2O < 100 mg/dm² to ISO 1776

- Alkali resistance - Alkali resistance class ISO 695-A2

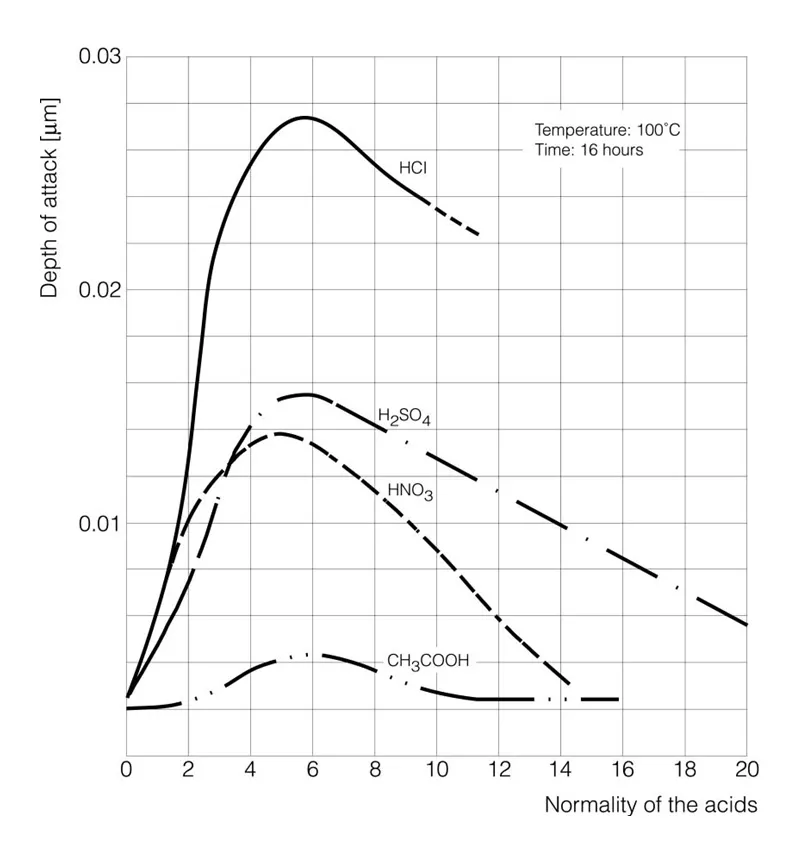

ATTAQUE ACIDE

Les courbes de corrosion montrent un maximum pour différents acides dans la gamme de concentration entre 4 et 7 N (HCl par exemple à l'azéotrope avec 20,2 % en poids). Au-delà, la vitesse de réaction diminue nettement, de sorte que la couche érodée ne représente plus que quelques millièmes de millimètre au bout de quelques années. Il est donc justifié de qualifier le verre borosilicaté 3.3 de matériau résistant aux acides.

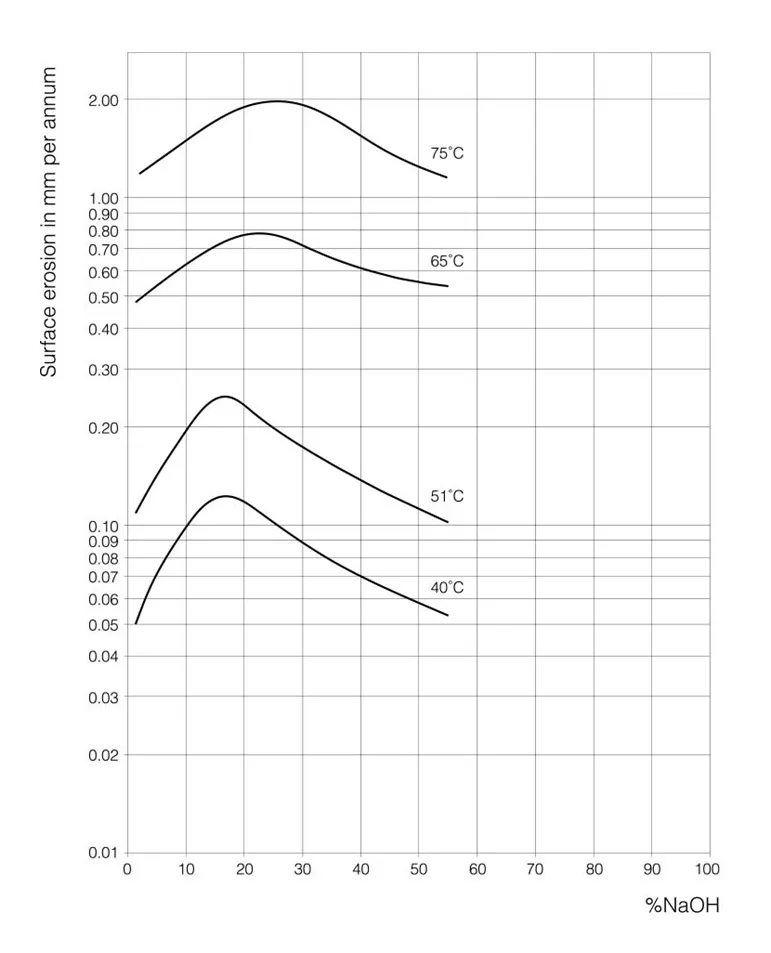

ATTAQUE PAR DES ALCALIS

On peut voir sur les courbes de corrosion que l'attaque sur la surface du verre augmente initialement lorsque la concentration de la solution caustique augmente, mais après avoir atteint un maximum, il assume une valeur virtuellement constante. Une augmentation de la température augmente la corrosion, alors qu'à de faibles températures, la vitesse de réaction est tellement faible que la réduction au niveau de l'épaisseur de la paroi est presque indétectable sur plusieurs années.

Physical Properties

Borosilicate glass 3.3 differs from other materials of construction used for process plant not only because of its virtually universal resistance to corrosion (see above) but also because of its very low thermal expansion coefficient. There is, therefore, no need for expensive measures to compensate for thermal expansion resulting from changes in temperature. This becomes of particular significance in the layout of long runs of glass pipeline.

The most important physical properties for the construction of plant are listed below (see also ISO 3585 and EN 1595).

- Linear thermal expansion coefficient - a 20/300 = (3,3 ± 0,1) x 10-6 K-1

- Thermal conductivity between 20 and 200°C - l 20/200 = 1,2 W m-1 K-1

- Specific heat capacity between 20 and 100°C - Cp 20/100 = 0,8 kJ kg-1 K-1

- Specific heat capacity between 20 and 200°C - Cp 20/200 = 0,9 kJ kg-1 K-1

- Density at 20°C - r = 2,23 kg dm-³

Mechanical Properties

The permissible tensile strength of borosilicate glass 3.3 includes a safety factor which takes into account practical experience on the behavior of glass and, in particular, the fact that it is a non-ductile material. Unlike other materials of construction used for similar purposes, it is not able to equalize stresses occurring at local irregularities or flaws, as happens in the case of ductile materials such as metals. The safety factor also takes into account additional processing which components may have undergone (ground sealing surfaces), handling of the glass (minute surface damage) and permissible pressures and temperatures to which it may be subjected in use.

The design figures indicated in the table below and specified in EN 1595 therefore apply to the permissible tensile, bending and compressive stress to which glass components may be subjected taking into account the likely surface condition of the glass in service.

- Tensile and bending strength - K/S = 7 N mm-²

- Compressive strength - K/S = 100 N mm-²

- Modulus of elasticity - E = 64 kN mm-²

- Poisson‘s ratio (transverse contraction figure) - n = 0,2

Vous avez des questions ?

Nos équipes sont prêtes à collaborer avec vous et à fournir des solutions pour vos projets