Evaporadores rotativos

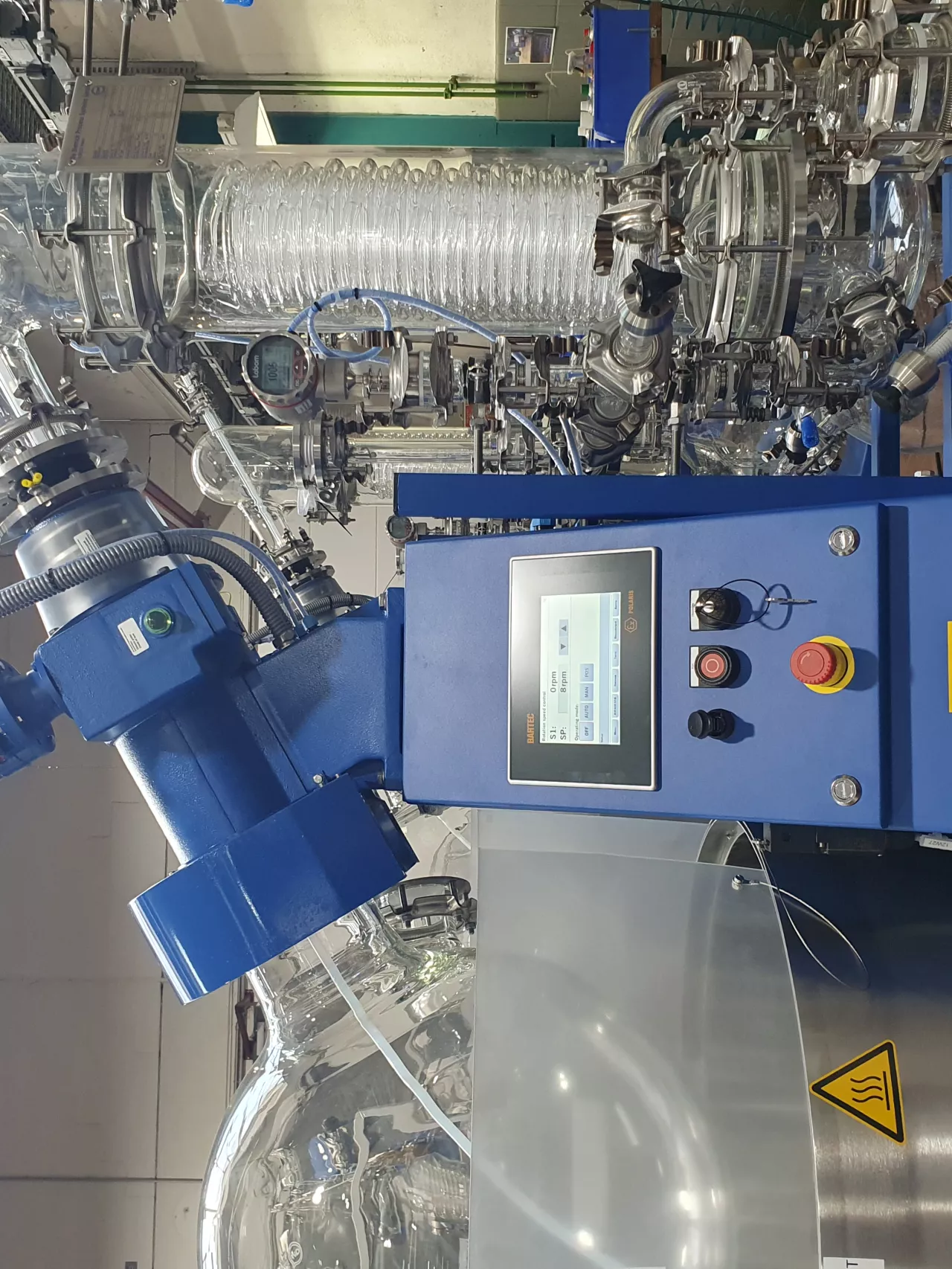

Solución QVF® ROTADEST para la evaporación de disolventes, cristalización, secado de suspensiones, polvos o gránulos, y diversas reacciones químicas en fase líquida o en zonas clasificadas Ex

Ventajas especiales del QVF® ROTADEST

- Vacío eficiente gracias a un cierre mecánico de alto rendimiento en PTFE/cerámica y sistema de bridas de vidrio certificado

- Sello mecánico en PTFE para funcionamiento con ligera sobrepresión o bajo vacío

- Uso exclusivo de materiales resistentes a la corrosión, como vidrio borosilicato 3.3 y PTFE, en todas las partes en contacto con el producto

- Certificados FDA para los materiales en contacto con el producto

- Unidad de accionamiento robusta para la esfera rotativa

- Sección de condensación adaptada al proceso

- Buena visibilidad de los procesos en curso

- Construcción industrial fiable y duradera

- Manejo sencillo

- Versión protegida para zonas con riesgo de explosión (Ex)

PUNTOS DESTACADOS

Unidad de accionamiento robusta para la esfera giratoria. Sección de condensación adaptada al proceso, observabilidad adecuada de los procesos. Disponible versión con protección Ex

Bajo vacío gracias al sello mecánico de PTFE de alto rendimiento y al sistema de brida de vidrio certificado. Cierre mecánico de PTFE para ligera sobrepresión o bajo vacío.

Uso exclusivo de materiales resistentes a la corrosión como vidrio de borosilicato 3.3 y PTFE para todos los componentes en contacto con el producto. Certificados FDA-Materiales para las superficies en contacto con el producto

Robusta unidad de accionamiento para la esfera giratoria. Construcción industrial fiable y sostenible. Funcionamiento sencillo

Evaporadores rotativos

El QVF® ROTADEST es una solución versátil para la evaporación de disolventes, la cristalización, el secado de suspensiones, polvos o gránulos, así como para realizar diversas reacciones químicas en fase líquida, incluso en zonas con clasificación Ex.

La solución más universal para una evaporación suave y eficiente

Los evaporadores rotativos se utilizan principalmente para evaporar componentes de bajo punto de ebullición a presión atmosférica o al vacío. En plantas piloto y producciones a pequeña escala, también son adecuados para la evaporación semidiscontinua. Se caracterizan por ofrecer un tratamiento térmico suave para medios sensibles a la temperatura y una velocidad de evaporación superior a la de los matraces de destilación de vidrio sin agitación.

A diferencia de otros procesos de evaporación, los evaporadores rotativos permiten eliminar todos los componentes volátiles y obtener finalmente un producto seco en el matraz.

Las condiciones de operación están limitadas por la temperatura máxima del baño calefactor (aprox. 160 °C), la temperatura del líquido de refrigeración (ej. 15 °C con agua corriente) y el rendimiento del generador de vacío (ej. ~10 mbar).

El QVF® ROTADEST puede suministrarse en versiones aptas para zonas clasificadas Ex hasta zona 1 IIB.

El líquido a procesar en el evaporador rotativo se introduce de forma discontinua, ya sea por gravedad, mediante una bomba o por aspiración al vacío en el matraz de evaporación.

El líquido a procesar en el evaporador rotativo se introduce de forma discontinua en el matraz de evaporación, ya sea por gravedad, mediante una bomba o por aspiración al vacío. Durante el proceso de evaporación, puede añadirse alimentación adicional utilizando los mismos métodos: bomba, gravedad o vacío, a través de una manguera de PTFE que atraviesa el eje rotativo y desemboca en el matraz esférico.

La esfera giratoria se sumerge parcialmente en un baño calefactor, lleno de agua o de otro fluido térmico adecuado. El baño, calentado mediante resistencias eléctricas, puede bajarse rápidamente para detener de inmediato el proceso de evaporación.

El giro de la esfera, acoplada a un motorreductor, garantiza una mezcla eficaz del producto en su interior y un mojado completo de toda la superficie interna, lo que aumenta la superficie de evaporación, mejora la tasa de evaporación y acorta el tiempo de proceso.

Los componentes con menor punto de ebullición se evaporan primero en la esfera en rotación. Sus vapores atraviesan un eje hueco integrado en el sistema de accionamiento y llegan al condensador, donde se condensan y, opcionalmente, se enfrían en un refrigerador de destilado antes de ser recogidos en un recipiente final.

- El tipo de evaporador más universal

- Evaporación suave gracias a la formación de película

- Evaporación hasta obtener el producto seco

- Reducción de la formación de espuma por menor burbujeo

- Prevención de ebullición súbita peligrosa (bumping)

- Diseño industrial fiable

¿Tiene preguntas?

Nuestro equipo está listo para colaborar con usted y ofrecer soluciones para sus proyectos.

Documentos para descargar

Solicitar una descarga

Con el fin de procesar su solicitud de folleto de manera eficiente, le rogamos que nos facilite la información requerida a través de nuestro formulario.