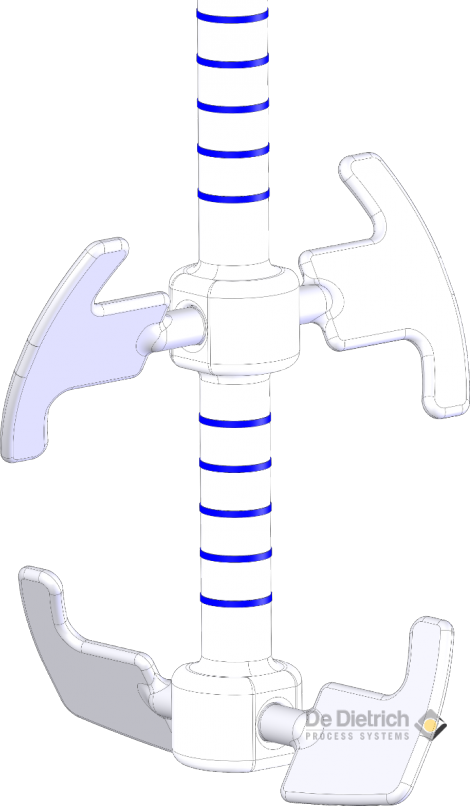

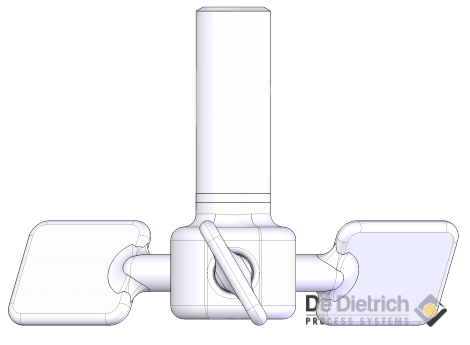

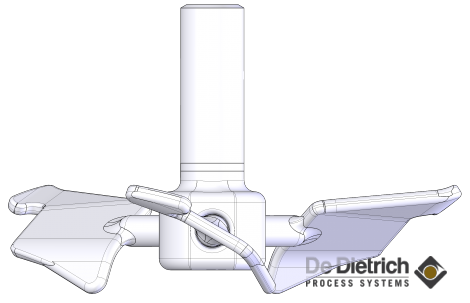

世界上唯一一个配有可拆卸叶片的系统

该系统专为主开口为检修孔的 BE 反应釜而设计,但是也可用于其他各种类型的反应釜。

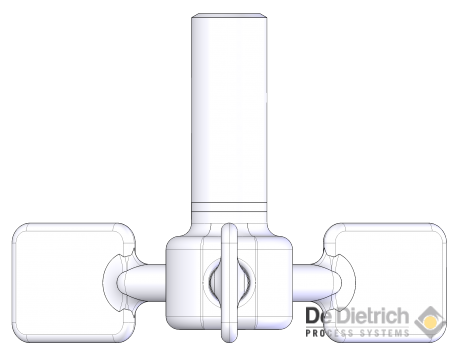

可横向安装和拆卸,无需完全拆下,便可操作刮擦搅拌器。 借助多层式搅拌器,在搅拌器保持原位的情况下,可修改其中一个工艺阶段,不会影响其他阶段。

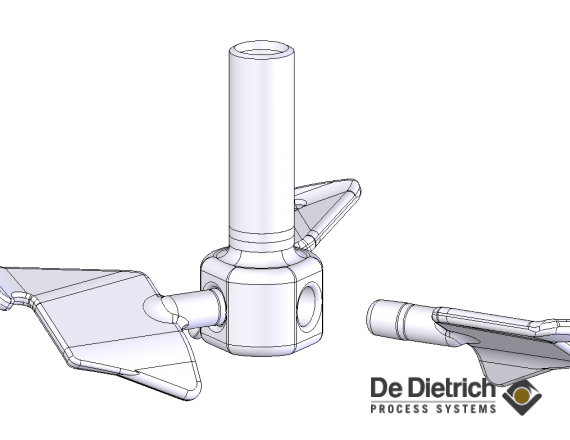

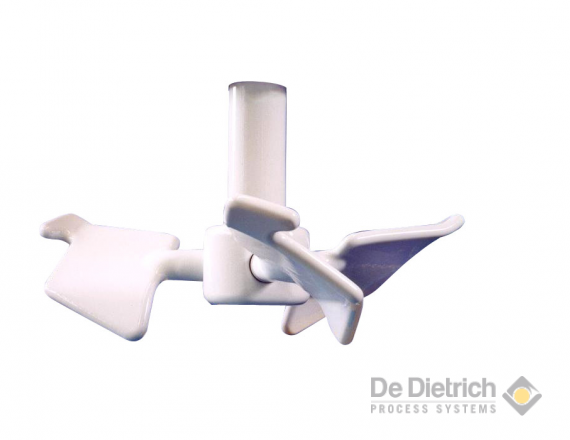

使用手动工具,按照简单的程序,便可将叶片安装到锥形位置,两者均覆盖搪瓷。 GlasLock® 使用一个叶毂,允许安装所有类型的叶片轮廓,从而提供更大的柔性。 该技术减少了拆卸驱动器(必要时)的时间。

我们的团队可根据您的工艺和您的搅拌参数,定义及安装叶片轮廓。借助这一技术,可装配各种不同的叶片,以更好地满足反应需求。

特性

GlasLock® 叶片采用 DD3009 玻璃衬里,以实现卓越的防腐蚀性。 其提供各种各样的叶片设计,以满足不同的工艺需求。

优势

- 多工艺系统

- 可独立拆卸叶片

- 搅拌体积小

- 易于维护

- 有限的叶片库存

The agitation characteristics are different in function of the blades angle and their design

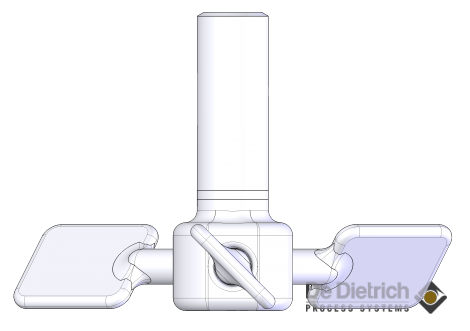

Blade angle at 90°

- 100% radial flow

- Very important shear

- Applications: all dispersion process

Blade angle at 60°

(the most common used position)

- 2/3 radial - 1/3 axial flow

- Important shear

- Applications: homogenisation, heat transfer, suspension

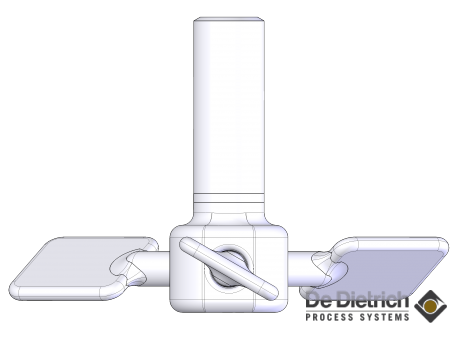

Blade angle at 45°

- 50% radial flow - 50% axial flow

- Medium shear

- Moderate agitation

- Pumping effect

- Applications: homogenisation, suspension

Blade angle at 30°

- 1/3 radial - 2/3 axial flow

- Low shear

- Moderate agitation

- Pumping effect

- Applications: crystallisation (fragile crystals)

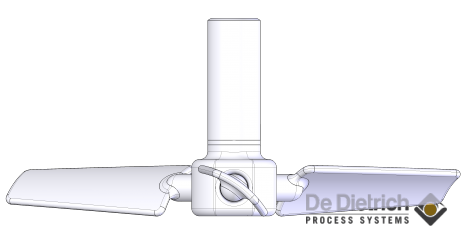

The Hydrofoil blades

Improvement of the pumping effect, low power consumption

- Major axial flow

- Medium shear

- Moderate agitation

- Applications: suspension of particles

- Dissolution, crystallisation (fragile crystals)

- Heat transfer

The Optifoil blades

- Run low volumes with high axial flow

- Facilitates the emptying of the reactor

- Do not damage fragile crystals

- Improved combination of Hydrofoil / Trapezoidal blades

- Improved suspension

- Strong flow close to the bottom

- Non agitated volume for 40m3 reactor: ±300 l

The Viscofoil blades

- Viscosity up to 120,000 cP

- Two kinds of blades Viscofoil (Bottom & Shell) designed to follow the profile of there actor angled at 45° to generate axial flow.