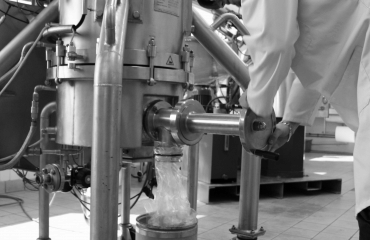

Pilot scale filter-dryer: RoLab

It is a manual solution for both laboratory and production environments that provides all the process functionality of filter-dryers

RoLab is a standardised unit designed for pilot scale, multi-product environments. Rolab is mobile, easy to install and operate, and available with filtration areas between 0.03 and 0.4 m². The standardised design allows significant cost saving compared to custom built units.

RoLab allows users to carry out all steps of a professional modern filtration and drying procedure under cGMP and FDA guidelines. The installation enables fast and frequent product changes and can be flexible due to its mobility. These features result in a high cost-effectiveness of the testing and manufacturing processes as well as the used capital goods.

RoLab impresses with its simplicity and focus on the essential. The machine has no hydraulic system and the extent of electronic function support is reduced to a minimum. The installation of RoLab is straightforward and fast. The filter/dryer only needs to be connected by the user with the supply lines:

• Compressed air

• Electricity

• Heating/Cooling

Subsequently, the process connections (suspension, nitrogen,

etc.) have to be attached and the RoLab is ready for operation.

Standard options

Heated agitator

Heated vessel cover

Side discharge valve for protected discharge of the product

Gas Knife system for complete discharge of the product

Dust filter for the improvement of the drying process

Mounting screws of the filter media placed outside of the product space

Attachment for sampling

WIP-device for efficient cleaning of the inner vessel

Tachometer of the agitator

Different control options

Containment systems

Applications