Back to Plant-based Chemistry

Contact us

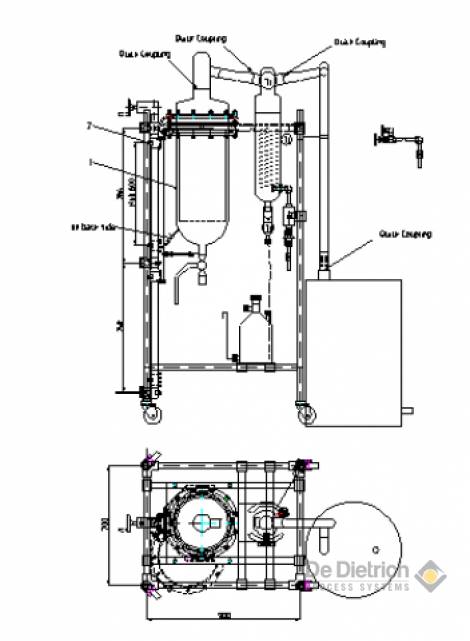

Hydro Distillation

Hydro distillation is an ancestral yet fundamental and still widely used method to extract essential oils from aromatic plants.

Several techniques of extraction can be applied, depending on the type of raw material to be processed. Direct steam injection is usually preferred, although in some cases water bath distillation is required.

If the raw material does not suffer from it, a distillation under pressure will usually save energy while increasing yield.

DE DIETRICH PROCESS SYSTEMS BENEFITS

- The raw essentiel oils produced in our hydro distillation units can be processed further in our distillation columns, to produce pure isolates or to remove undesirable components.

MAIN FEATURES

- From simple economic stills for direct steam injection at atmospheric pressure, to multipurpose unit working up to 2,5 barg

- Water bath distillation stills are featured with anchor type stirrer for efficient mixing of the biomass in water

- Loading systems include simple perforated grid with chains, multiple superimposed grids, baskets… Automatic loading /unloading systems can be fitted to units

- The heat exchangers design allows a tight control of the distillate temperature, to help the separation of oils and distillate water

- Complete oil separation and recovery is ensured by a range of decanters for light oils, heavy oils, or a combination of both. Addition of coalescers and internal heating/cooling systems can ease the separation

- Cohobation skid allows to cohobate the distillate water even when working with distillation under pressure

TIPS

- Our small scale miniplant, all glass-made, is the perfect tool to identify and test the best process parameters to extract unaltered pure essential oils

Which kind of industry can use this product?

Questions? We are here to help.

If you'd like to talk with a sales representative about purchasing De Dietrich Process Systems's products and services, you can reach us here.

Contact us Documents