QVF® Dosing Pump

- Constant flow rates -

- Reproducible flow rates -

- 2,1 to 1140l/h -

- For Ex-rated areas -

- Visible flow -

- safe dry running -

- easy maintenance -

General Introduction

The QVF® Bellows pumps are hyghly corrosion resistant dosing pumps with robust and long term reliable industrial drives, which can be installed in Ex-rated ares. As metering pumps they are characterized by an high efficiency, a relative unsensitivity towards cavitation and a reproducible adjustment of the flow rates. When switched off they inhibit the fluid flow backwards and are hermetically tight towards the outside. Therefore they are perfecty suited for the dosage of highly corrosive liquids as e.g. strong mineral acids at the following operating conditions:

- Flow rates: 2,1 to 1140l/h

- Pressure: max. 3,5barg

- Temperature of the liquid: -10 to 100°C

- Viscosity of the fluid: max. 200mPas

- Required NPSH-Value: 4,7m

- EX-Area: Zone 1 IIB

| Size / Type | Flow Rate | Stroke Length | Frequency | Rotating Speed | Capacity | Pressure | Temperature | NPSH |

| l/h | mm | 1/min | 1/min | kW | barg | °C | m | |

| DN20AT-SL | 2,1 - 21 | 0 - 20 | 53 | 1500 | 0,18 | +3,5 | -10 - +100 | 4,7 |

| DN40AT-SL | 4,2 - 42 | 0 - 20 | 106 | 3000 | 0,25 | +3,5 | -10 - +100 | 4,7 |

| DN55AT-SL | 5,8 - 58 | 0 - 20 | 53 | 1500 | 0,18 | +3,5 | -10 - +100 | 4,7 |

| DN110AT-SL | 11,3 - 113 | 0 - 20 | 106 | 3000 | 0,25 | +3,5 | -10 - +100 | 4,7 |

| DN300AT-SL | 30,0 - 300 | 0 - 20 | 106 | 3000 | 0,25 | +3,5 | -10 - +100 | 4,7 |

| DN500AT-SL | 52,0 - 520 | 0 - 20 | 106 | 3000 | 0,25 | +3,0 | -10 - +100 | 4,7 |

| DN750AT-SL | 77,0 - 770 | 0 - 30 | 106 | 3000 | 0,37 | +3,0 | -10 - +100 | 4,7 |

| DN1100AT-SL | 114,0 - 1140 | 0 - 30 | 155 | 3000 | 0,37 | +3,0 | -10 - +100 | 4,7 |

Within the indicated flow range the correlation between the stroke lenght and the flow rate is linear

Technical Description

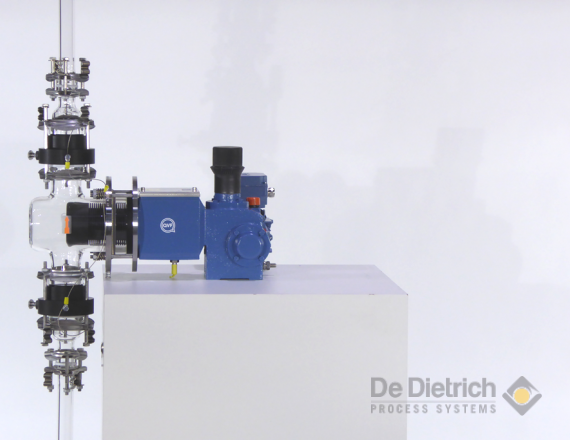

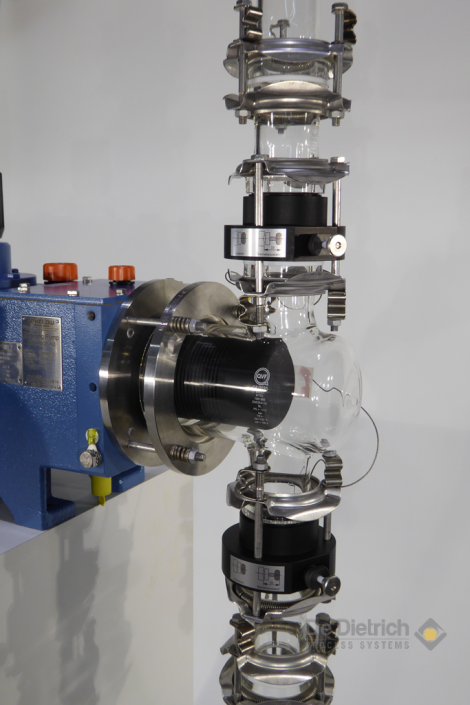

The QVF® Bellows dosing pump consists mainly of the pump head, transporting the liquid, and the corresponding pump drive. The proven highly corrosion resistant pump head developped by us throughout the last decades is combined with an extremely reliable Bran-Luebbe®-Drive made by SPX FLOW Technolgy so that you can benefit from reliable complete solution. These pumps can be easily integrated into glass and glass-lined systems.

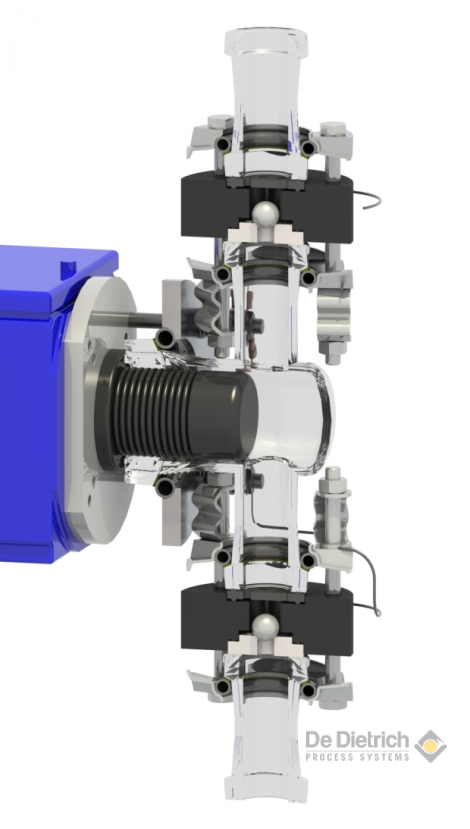

Pump Head

The QVF®-Pump type DN replaces with a metering piston bellows the liquid inside the single-item pump head and moves the liquid through the gravity operated ball valves. The bellows themselves serve as gasket at the bottom of the pump head and hences seals the pump head towards the drive as well as towards the piston. The housing of the pump head is made of borosilicate glass 3.3 enabling the visual observation of the pumping process.

Components of the QVF® bellows dosing pump in contact with the liquid consitit of:

- Housing of the pump head: Borosilicate glass 3.3

- Housing of the ball valve: dissipative black PTFE

- Valve seat: ceramic

- Ball of the valve: Borosilikate glass 3.3 or Tantalum if the density of the liquid is higher than 1200kg/m³

- Bellows: dissipative black PTFE

The housing of the pump head as well as the succion and pressure side of the pump are equipped with the robust glass flanges of the QVF® SUPRA-Line. This way the pump can not only be easily connected with standard components to glass components of the QVF® SUPRA-Line but also to all the former glass systems offered by QVF and SCHOTT. In an analogue manner these pumps can be connected to glass-lined and stainless steel flanges.

The still standing pump is drained backwards againts the pumping direction. To do this knurled screws in the PTFE housing of the ball valves are screwed towards the inside to lift the balls from the valve seat enabling a full drainage.

Empty line to generate FULL WIDTH

Pump Drive

The movement of the oscillating bellows piston is done by a proven Bran-Lübbe pulsator made by SPXFLOW. At a constant speed of the IP55 protected pump drive the flow rate is a function of the stroke length. Its adjustment is done by means of a very detailed scaled manual wheel which is operating a worm gear. Alternatively are an electrical or a pneumatic adjustment with an actuation controller and limit switches is available ( control pressure: +0,2barg to +1,0barg, operating pressure +2,5barg to +6barg). The drive is classified according to EEx 2IIG c IIB T4 and can operated reliably between 0 and +40°C with a electric 3-phase motor at 230/400V 50Hz - alternative power supplies are available upon request.

®®Empty line to generate FULL WIDTH

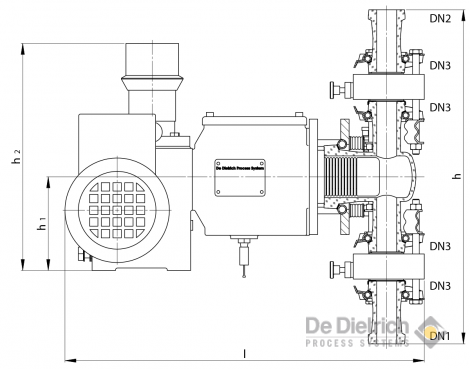

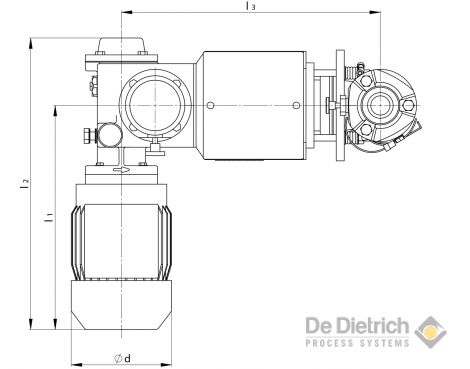

| Size / Type | DN1 / DN2 | DN3 | h | h1 | h2 | l | l1 | l2 | l3 | d |

| mm | mm | mm | mm | mm | mm | mm | mm | |||

| DN20AT-SL | 15 | 15 | 335 | 112 | 272 | 402 | 279 | 363 | 335 | 125 |

| DN40AT-SL | 15 | 15 | 335 | 112 | 272 | 402 | 279 | 363 | 335 | 125 |

| DN55AT-SL | 25 | 25 | 400 | 112 | 272 | 430 | 279 | 363 | 323 | 125 |

| DN110AT-SL | 25 | 25 | 400 | 112 | 272 | 430 | 279 | 363 | 323 | 125 |

| DN300AT-SL | 25 | 50 | 547 | 112 | 272 | 480 | 279 | 363 | 360 | 125 |

| DN500AT-SL | 25 | 50 | 580 | 112 | 272 | 514 | 279 | 363 | 377 | 125 |

| DN750AT-SL | 50 | 50 | 580 | 162 | 425 | 612 | 346 | 492 | 457 | 140 |

| DN1100AT-SL | 50 | 50 | 580 | 162 | 425 | 612 | 346 | 492 | 457 | 140 |

Line to generate FULL Width