Big Bag Emptying Station

Seamless integration within your process.

From easy flowing to the most consolidated powders, De Dietrich Process Systems has the solution to safely discharge powder from Big Bags into the next step of your process. Typically used for raw or intermediate products, the units can be dedicated to a single product or be adaptative and multi-purpose for maximum flexibility.

Units can be customised for difficult environment and be adapted to the less usual situation in plants (in case of retrofits in existing environments).

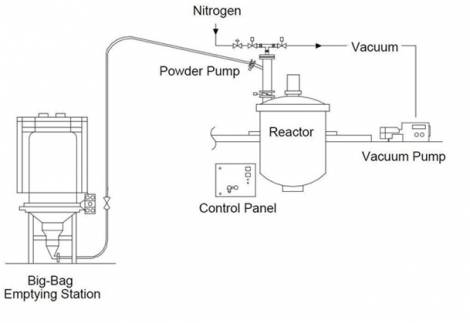

The range of options available allows the versatile Big Bag Station to work seamlessly with the De Dietrich Process Systems Powder Pump or to gravity feed directly into a glass lined reactor other process equipment. Control is typically done with a PLC and HMI, suitable for hazardous area. Weighing can be performed to measure the amount of powder offloaded.

Benefits

- Seamless integration with other process equipment

- Adaptable to many bag sizes and designs

- High containment options available

- Cleanable in place (CIP)

- Loss-in-weight measurement available

Characteristics (depending on options)

- Integrated runway beam and pneumatic or electric hoist/trolley

- Material flow promotion massaging arms

- Fluidising hopper to address material flow issues such as bridging and ratholing

- Automatic bag tensioning to assist discharge

- Dust free bag outlet spout sealing clamp and containment housing

- Load cells for batch weight monitoring and control

- In-Line de-lumping/milling available

- Integrated hydraulic bag crusher for extremely compacted product

- High containment cabinet available for potent products