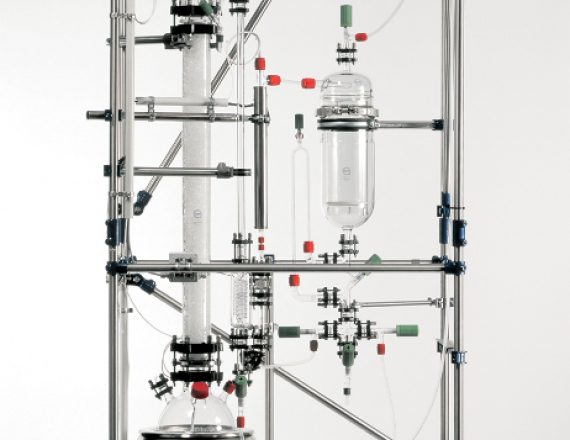

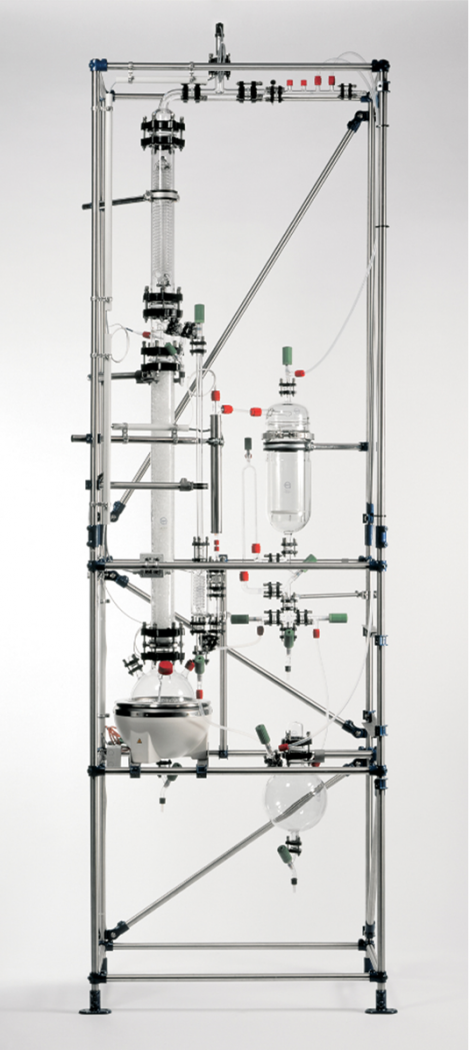

1,5l Solid/Liquid Extractor

• Various extraction modes for multiple applications

• Solvent preparation

• Preconcentration of the extract

• Compact Miniplant solution

• Comprehensive assessment of the process parameters

• Fully corrosion resistant

Concept

- Compact and versatile extraction system for quantities of solids above laboratory scale ~ ~1,5l of solids.

- Measurement and control equipment for the comprehensive assessment of the process data.

-

3 different extraction modes:

- Trickle bed extraction

- Underflow extraction

- Soxhlet extraction

- Solvent preparation with a 6l spherical evaporator with an electrical heating jacket.

- The temperature of the solvent for the extraction can be freely adjusted between the temperature of the cooling fluid and the boiling point of the solvent

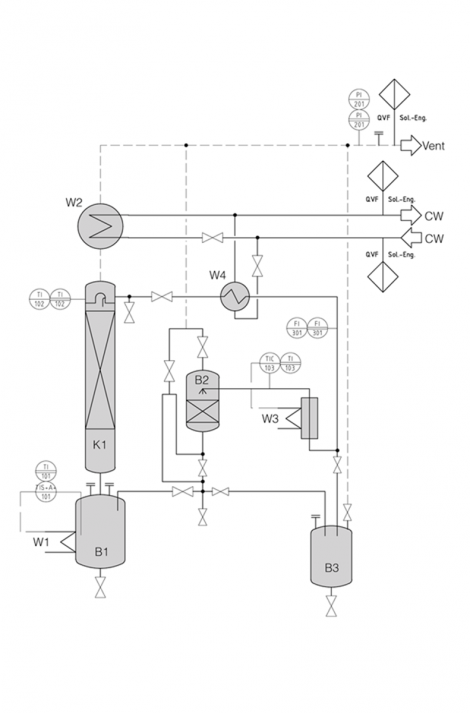

Function

A basket which can be filled with solids outside the system is accommodated in the extraction receiver. A valve after the bottom outlet of the extraction receiver permits to select the extraction mode. If open, the trickle bed mode is selected and if closed a vent valve on top of a loop pipe permits to select between Soxhlet and underflow extraction mode. The solvent containing the extract is then guided either in a final receiver or to the evaporator. The solvent vapors from the evaporator are condensed in an uprising condenser and hence withdrawn at boiling temperature of the solvent and can then be cooled down. If required, it can then be heated to the required well defined extraction temperature. The prepared solvent is then fed into the upper part of the extraction receiver dripping on top of the solids in the basket. After the extraction the basket can be taken out of the extraction receiver and discharged, cleaned and reloaded outside of the system.

Technical description

The 1,5l basket containing the solids is a cylindrical receiver with a porous sintered glass plate at the bottom. The basket can be placed easily into the 4l extraction receiver (B2) due to a quick release coupling DN150. Compact valves control ventilation, product and cooling fluid flows. The 6l spherical evaporator (B1) is electrically heated. The column DN80 (K1) is fill with Raschig-rings. The vapors are condensed in a vertical coil type glass condenser (W2). The reflux is manually adjusted. The coil type distillate cooler (W4) can also be disconnected from the cooling fluid circuit not to cool down the solvent. An temperature controlled electrical heater (W3) can be used precisely control the temperature of the solvent entering the extraction receiver.

Technical Data

- Basket for solids in B2: 1,5l

- Filter/support of solids: Sintered glass plate

- Extraction receiver B2: 4l

- Evaporator B1: 6l, 1700W

- Distillate Receiver B3: 6l

- Column K1: DN80 with Raschig-rings

- Condenser W2: 0,3m2

- Heater W3: 300W

- Cooler W4: 0,03m²

- Dimensions: 1000 x 600 x 3300mm

- Ex-Zone in-/outside: non

- Extraction Temperature: 20 up to 150°C

- Extraction pressure: -1 up to atmospheric pressure

- Material in contact with product: Borosilicate glass 3.3, PTFE, PFA