8l Jacketed Solid/Liquid-Extractor

• Gentle motion/smoothening of the solids by a manual stirrer

• Lowering device for easy removal of the extraction basket

• Automated solvent flow through the extractor

• Solvent preparation

• Cycling the solvent

• Ex-protected version

• Pilot Plant Solution

• Fully corrosion resistant

Concept

- Manual extraction system for kg-quantities of solids.

-

Extraction modes:

- Trickle bed extraction

- Underflow extraction

- Solvent preparation with a 25l stirred evaporator with a jacket for heat transfer fluid.

- The temperature of solvent for the extraction is close to its boiling point and can be regulated by the applied vacuum.

- The temperature of the extraction receiver can be adjusted.

- The flow rate of the solvent is automatically controlled.

Function

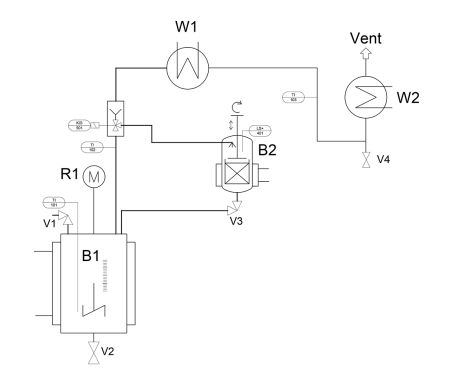

A basket which can be filled with solids outside the system is accommodated in the extraction receiver. The hot solvent is fed into the upper part of the extraction receiver dripping on top of the solids in the basket and trickling though the solid material. A bottom outlet valve of the extraction receiver permits manual control of the extraction mode – trickling, flooding and draining. The solvent containing the extract is then guided back to the jacketed stirred evaporator. The solvent vapors from the evaporator are condensed in an uprising condenser and withdrawn by an automated reflux divider. The set points of the evaporation rate and reflux ratio control the flow rate of the solvent. The distillate take-off at boiling temperature is then guided directly to the extraction vessel. The extraction vessel is equipped with a level switch to detect eventual overflow. After the extraction process the extraction vessel can be lowered to easily take out the extraction basket for discharging, cleaning and reloading with fresh solids outside of the system.

Technical description

The 8l basket containing the solids is a cylindrical receiver with a porous sintered glass plate at the bottom. The basket can be placed easily into the 10l extraction receiver (B2) due to a lowering device for the lower part of the jacketed extraction receiver. A manual stirrer in the basket which can be moved up- and downwards permits to gently move the solids in the extraction basket during the extraction process. Compact bellow valves control ventilation and product flows. The 25l stirred evaporator (B1) is jacketed to be heated with a heat transfer fluid. The vapor pipe DN50 connects the evaporator to the inclined coil type condenser (W1). The distillate take-off is adjusted by a magnetically actuated funnel.

Technical Data

- Basket for solids (in B2): 8l

- Extraction receiver (B2): 10l

- Evaporator (B1): 25l

- Vapor pipe (K1): DN50

- Condenser (W1): 0,7m2

- Vent condenser (W2): 0,6m²

- Dimensions: 2600 x 900 x 1800mm

- Ex-Zone in-/outside: 1/1 II B

- Extraction Temperature: -20 up to 150°C

- Extraction pressure: -1 up to atmospheric pressure

- Material in contact with product: Borosilicate glass 3.3, PTFE, PFA