Glove boxes

A glove box adapted to each process

Meeting the high safety and containment requirements necessary when handling sensitive or hazardous substances such as HPAPIs - Highly Potent Active Pharmaceutical Ingredient - can be extremely challenging.

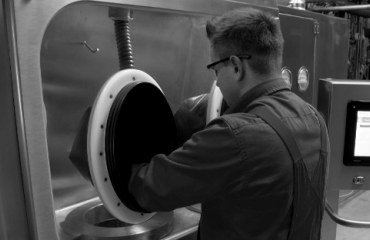

With the right glove box design, handling these powders becomes safer and more efficient. Glove boxes reduce the need for PPE (Personal Protective Equipment) and simplify the operator’s job. The workstation is not only easy to use, it is also easy to clean thanks to CIP (cleaning-in-place) systems.

To achieve the best results in terms of containment and simplicity, our team works closely with yours to the design of the glove boxspecific to your process requirements.. Each model is adapted to the installation constraints and to the toxicity of the product, even CMR or cytotoxic. De Dietrich Process Systems covers the installation of glove boxes for most of the needs ranging from reactor loading to filter / dryer discharging and powder pack-off.

Benefits:

- Customized solutions up to OEB 6

- Containment of all stages: loading, production, discharging, maintenance, washing

- Protection of the most sensitive products with nitrogen inerting

- cGMP and/or ATEX compliant glove boxes

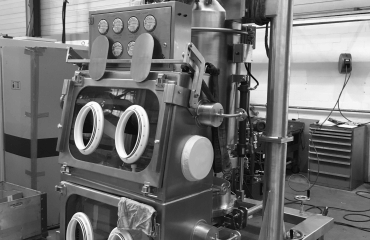

Improve the containment of your existing installations

To improve the safety of your existing installations, it is not necessary to redesign all the equipment. Glove boxes are easily implemented on existing equipment like filter / dryers. De Dietrich Process Systems takes care of all the operations to integrate interfaces, automation systems, safety interlocks and other peripheral components.

The revamping of glove boxes on existing equipment is useful to reinforce the level of protection of your products and your operators, and install a new HPAPI production onto an existing line.

. Additionally, powder containment in filter / dryers can be further enhanced with the connection to pack-off systems, featuring continuous liners for contained dosing and filling. As with the installation of new equipment, the designs are custom-made according to the existing space constraints and safety requirements.

Benefits :

- Turnkey solutions adapted to existing equipment

- User-friendly

- Reduced need for PPE

- Reduced risk of product contamination

Applications