Extraction

- Experience enables the solution -

General Information

The dissolving process of a chemical component with a liquid out of a second non-gaseous phase is called extraction. The dissolving process of a chemical component with a liquid out of a second non-gaseous phase is called extraction. Depending on the kind of the second phase this process is named either solid/liquid extraction or liquid/liquid extraction.

Liquid/Liquid Extraction Solutions:

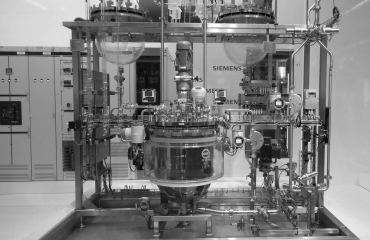

- Batch operated Mixing/Settling Units

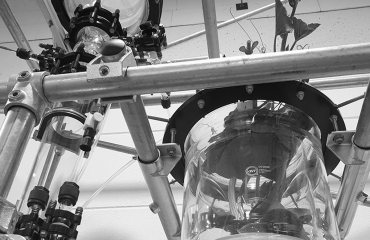

- Continuously operated Mixer-Settlers

- Continuously operated Extraction columns

Solid/Liquid Extraction Solutions:

- Soxhlet Extraction Units

- Trickle Bed Extraction Unit

- Over Flow Extraction Units

Empty line to generate a FULL WIDTH

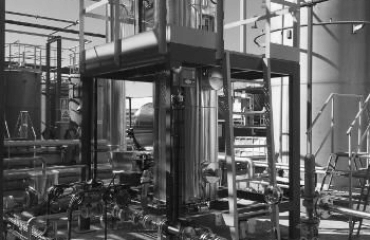

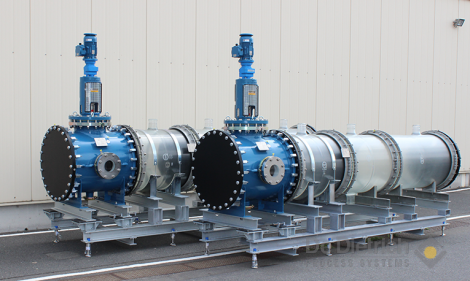

De Dietrich Process Systems not only provides the equipment for the extraction but also the process and complete process plants for the recovery of high boiling organic components out of industrial effluent water incl. the solvent regeneration as e.g. for these

Industrial Applications

Your Benefit

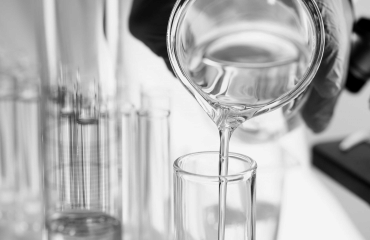

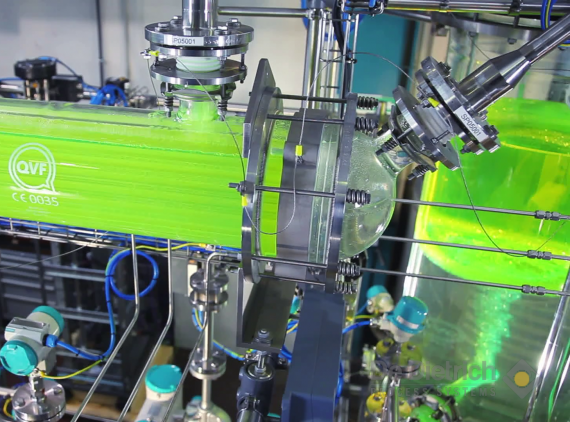

De Dietrich Process Systems has gathered through decades experience to design these extraction processes providing the most suitable equipment. These extraction plants are built by De Dietrich Process Systems from the most appropriate materials with respect to investment and maintenance costs. De Dietrich® glass-lined and QVF® borosilicate glass components provide an unbeaten corrosion resistance where necessary otherwise stainless steel is used. The transparency of QVF® borosilicate glass 3.3 eases the optimization of these extraction processes which very often have to be adapted to a specific task.

Beside theoretical calculations and extraction expertise gathered along the past De Dietrich Process Systems will be pleased to carry out trials in our experimental hall to develop the optimum process and to select the most suitable extraction equipment for your application.

Applications