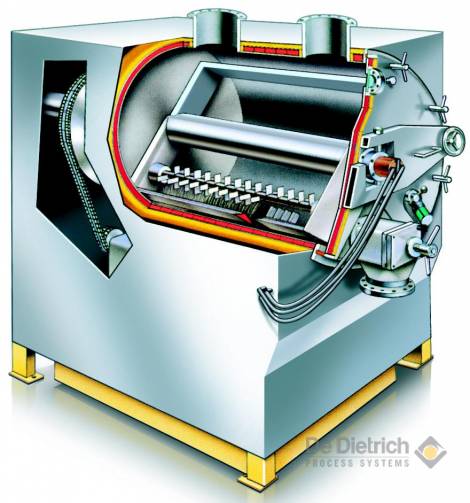

Universal Dryers

Maximum flexiblity and efficiency

Maximum heat transfer input to the product is achieved by heating the total vessel area and the agitator. A further advantage is the formation of an especially fine product powder in the dryer, which accelerates the heat transfer and thus the drying. The particle size of the product can be decrease further by the addition of a fixed stator to the agitator system.

Huge flexible degree of filling due to a high torque and a very good mixing effect of the agitator/chopper system.

Hydraulic drives for the agitator and chopper ensure a consistently high torque, even with low rotational speeds. Therefore the dryer can be filled between 20-90% of total capacity whilst retaining optimal agitation, mixing and drying performance. This huge degree of flexibility makes it possible to dry batch sizes that have greatly varying volumes and products that have greatly varying physical characteristics. Regardless of whether you have suspensions, solutions or filter-moist products – lumpy transition phases in which the agitator and chopper require more power can be easily overcome.

Wet or dry chopping.

Wet or dry chopping with the chopper/stator combination can make further milling or sieving steps unnecessary. The wet milling reduces the thermal strain on the product. In addition, a good milling effect is often achieved with an appropriate grain size distribution. For products that are sensitive to high-shear agitation, the chopper can be removed quickly and easily.

Advantages

Controlled product temperature and no crust formation

Agitator to wall clearance prevents crust formation and product overheating

The special construction of the agitator (results in a typical wall clearance of 2-5 mm) therefore the entire interior surface of the dryer is evenly coated. Crust formation is therefore absolutely minimised and heat is applied evenly to the product during the entire drying process. Since the agitator is supported at both ends of the shaft, it results smaller wall clearances than those in spherical and pan dryers can be achieved whilst maintaining the very high agitator torque!