Materials recovery for the production of Bovaer®

Our costumer dsm-firmenich is a global purpose-led science-based company active in Health, Nutrition and Bioscience. dsm-firmenich realize a new plant for its feed additive for ruminants, Bovaer® at its existing site in Dalry, Scotland.1

Bovaer® serves to reduce the amount of greenhouse gases in particular methane caused by the farming of livestock. Just a quarter teaspoon of Bovaer® per cow per day reduces methane2 emissions from dairy cattle by 30% and up to 45% for beef cattle, on average.3 This means a reduction in greenhouse gas emissions of 10-15% per kilo of milk.4 Bovaer® has been researched and developed for nearly 15 years by DSM.

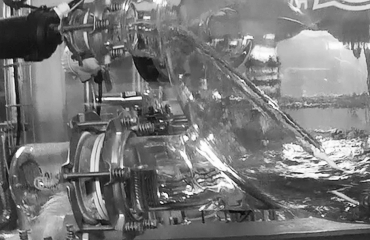

The production of Bovaer® requires, among other things, materials recovery in a closed-loop process. De Dietrich Process Systems in Mainz has deep knowledge and proven QVF® processes for MINERAL ACID TREATMENT, realised with reliable equipment from the whole De Dietrich Process Systems Group.

Since 2019, DSM and our Process Units team in Mainz has been working together to adapt the proven QVF® processes for MINERAL ACID TREATMENT to the requirements of the production of Bovaer® in Dalry. We started with trials on pilot scale, the engineering study and did the concept engineering and extended basic engineering.

All technical requirements were met. A system was engineered that is characterised by a high degree

of complexity, automation, flexibility, and reliability. The ecological footprint of the Bovaer® production was minimised from the start, for example through internal heat recovery etc. We are proud to have been awarded the contract for the detailed planning and supply of the processrelated equipment. A team from different parts of the De Dietrich world is now in place. Expertise’s and resources from Mainz, Zinswiller, Wuxi and Stafford will be used to manufacture essential parts of the plant and to provide service for the project. We will make major efforts to meet the high requirements in project execution.

Bovaer’s® Dalry plant is expected to enable the reduction of 4 million tons CO2 equivalent per year through the reduction of methane emissions from cows. In order to realise the potential of Bovaer®, the production capacity must be expanded. De Dietrich has the possibility to be a relevant part of the solution to significantly reduce the carbon footprint of livestock farming.

Mainz Germany, Mai 2024

1 https://www.dsm.com/corporate/news/news-archive/2021/34-21-dsm-plans-new...

2 https://www.globalmethanepledge.org/

3 https://www.dsm.com/anh/products-and-services/products/methane-inhibitor...

4 Canada approves Bovaer® as first feed ingredient to reduce methane emissions from cattle (dsm.com)