Cleaning Studies

The cleaning solution for your equipment

WHY INVEST IN CIP: Cleaning In Place?

- To save TIME by optimizing your reactor operation

- To reduce SOLVENT consumption for cleaning

- To define a repetitive cleaning cycle for CONSTANT efficiency

NUMEROUS SOLUTIONS HAVE BEEN DEVELOPED TO MEET YOUR NEEDS:

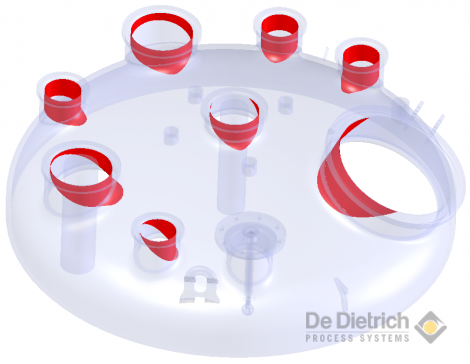

- Specific reactors

- In place or removable CIP solutions

- Many CIP systems in stock

- Testing tools

- Various materials available (Enamel, Stainless Steel, PTFE, ...)

A solution adapted to your specifications

Our approach in 3 steps:

- Step 1: Cleaning specification sheet to understand your requirements

- Step 2: Optimized reactor design using results of cleaning study

- Step 3: Validation testing in our workshops or at your site

The cleaning of your reactor is optimal

De Dietrich Process Systems designs the whole CIP system for your specific application.