Contained Drum Unloading System

Our client is a Nuclear fuel rod assembly facility.

The client needed to replace existing Screw & Cable disc conveyer. As a matter of fact, the client has to cope with frequent mechanical failures due to residual material. He also adressed some containment issues. On top of that, he wanted to control Transfer Rate & Batch Weight and to establish communication with plant DCS System.

De Dietrich Process Systems analysed the demand and proposed the following solution:

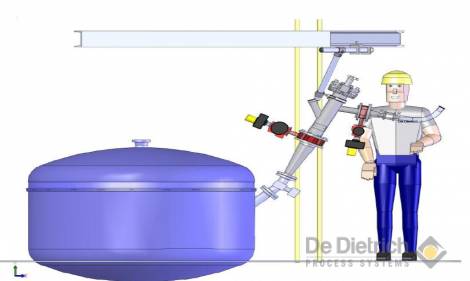

- PP-4 System with Powder Outlet Dispersion Device

- MTS Drum Unloader Unit

–1,200 lbs. Lifting Capacity

–Safety Caging & Light Curtains

- PLC Based Control System

–PLC & HMI with Integrated Motor Starters

–Ethernet Communication to DCS

- Full Factory Acceptance Testing

–Drum Weight Lift Test

–Surrogate Powder Transfer Test

- Keys:

–Willingness (Hungry)

–Resources in Place

–Good Supply Partner