Pharma Reaction System

- 16 to 63l compact version -

- Maximum heat transfer -

- Perfect oberservation of the process -

- Fulfilling GMP requirements -

- Self-draining -

Characteristics

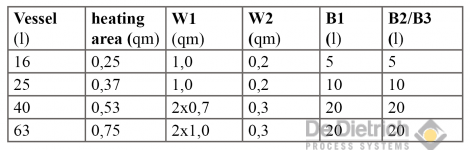

The Pharma Reaction System is designed in a compact layout for standardized capacities from 16 to 63l. Systems combining a glass-lined vessel with a glass dome for perfect observation of the process can be realized up to 630l.

Function

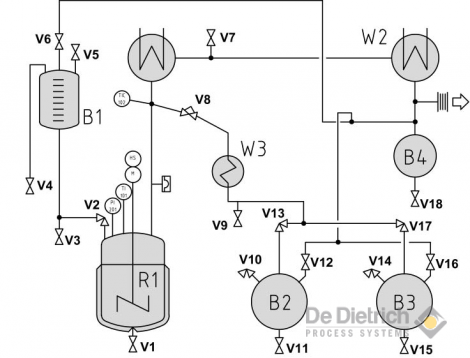

The Pharma Reaction System is specially designed for two process stages: reaction and distillation. The reaction stage operates under total reflux (V8 closed) whereupon the solvent can be distilled off (V8 open) in the concentration phase. Both processes can be operated at slightly overpressure (+0.6barg) or vacuum.The materials of construction used are borosilicate glass 3.3, glass-lined steel and PTFE.

Distillation Overhead

The distillation overhead complies with the Pressure Equipment Directive. All glass components from DN25 are labelled with the CE mark.

The assembly provides not only a GMP-compliant flange coupling but also a wide variety of well thought through individual solutions. To ensure that the equipment drains completely the horizontal product filled piping is largely installed at an angle of 5°. The inclined condenser is equipped with a cleaning nozzle and the receiver vessel can be emptied and rinsed during the process by means of valve V3.

The integrated sampling valve V9 is used for taking samples out of the current distillate flow even under vacuum, valve V8 adjusts the reflux.

The basic version of the Pharma Reaction System provides instrumentation covering all basic functions: the temperature of the vessel content and the distillate are indicated as well as the operating pressure by a tantalum membrane manometer. A bursting disk provides protection against overpressure. The rotation speed of the glass-lined impeller stirrer can be adjusted by means of the hand wheel on the drive.

All instruments can be easily assigned to the correlating vessels. This enables a direct and accurate operation.

Innovative Reactor

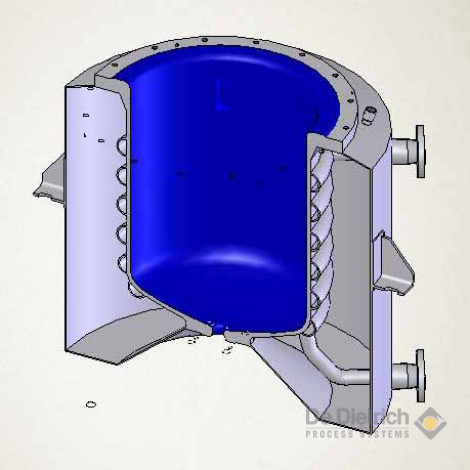

The glass-lined reaction vessel developed by De Dietrich Process Systems combines the following special features:

- Upper block flange for the connection to the glass cover by means of a GMP gasket

- Heating jacket up to the flange

- Support brackets without thermal bridge

- Block flange with minimal dead space bottom outlet valve

- Polished insulating jacket with foam glass, stainless steel, tightly welded

- White enamel to improve visual control

Buttress End with GMP Gasket

In addition to its basic benefits two special features predestine the flat QVF® SUPRA-flanges for the design of GMP-compliant apparatuses and plants. All nominal diameters up to DN300 have a fire-polished sealing surface as well as a groove.

The groove is positioning and stabilizing the PTFE gasket to the extremely smooth sealing surface.

Combining the flat QVF SUPRA-flange with the standard GMP gasket results in a flange connection with a minimal dead space. Pipelines at an angle of approximately 5°can therefore be completely drained.

Modular Construction

The basic version of the Pharma Reaction System can be modulary expanded. The following options are available:

- Hydraulic lifting device for the reaction vessel

- Phase separator

- Electronic speed indicator

- High pressure version

- Coated glass components

- Weighting cells for reaction, feed and distillate vessels

- Double-acting mechanical seal

- Anchor, turbine and propeller type stirrers

- Process control engineering