Structured packing DURAPACK®

- highly corrosion resistant -

- high separation efficiency -

- low pressure drop -

Concept

Thermal separation processes are often used in treating and cleaning chemicals. Very common are processes that involve two liquids or a liquid and a gas. The processes used mainly involve extraction, absorption, desorption or stripping, distillation or rectification. These separation processes require mass transfer between two phases; in the above rectification example, the mass transfer between the liquid and gas phase. Keeping the equipment used in this process as compact as possible requires creating as much mass transfer surface in as small a volume as possible. DURAPACK® ensures high flow rates with low pressure drop and at the same time huge mass transfer areas for an efficient separation.

In order to intensify the mass transfer in absorption, desorption, distillation and extraction columns structured packing DURAPACK® from borosilicate glass 3.3 is the best choice for corrosive media. Applications are among other are therefore corrosive chemicals such as sulfuric acid, nitric acid, other mineral acids such as HCl but also halides such as chlorine, bromine and iodine: short wherever metal material but also plastic fail.

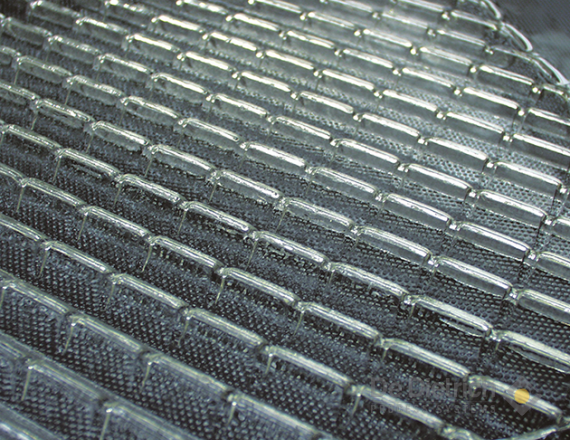

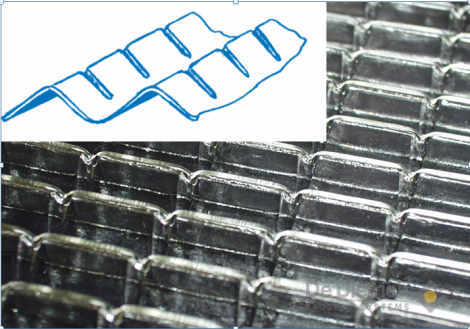

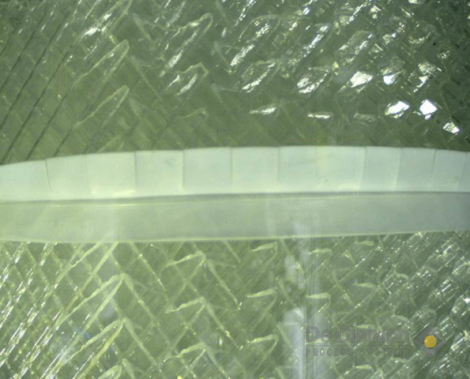

DURAPACK® patented structured packing consists of alternately allocated corrugated plates made of borosilicate glass 3.3 with channels at an angle of 45°. In order to increase the turbulence the corrugations are notched. The packing is only made from borosilicate glass 3.3, i.e. the plates are sintered together without any gluing material so that only borosilicate glass 3.3 is in contact with the media to be processed.

The easy-to-clean smooth and inert surface is extremely convenient.

DURAPACK® - Corrugated glass plates with notches

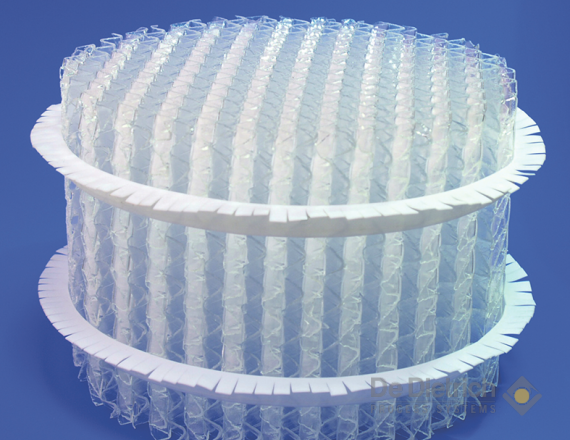

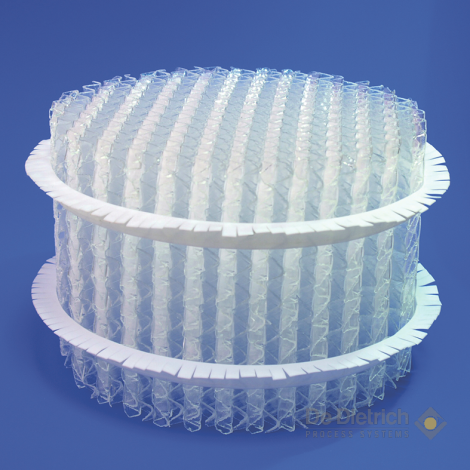

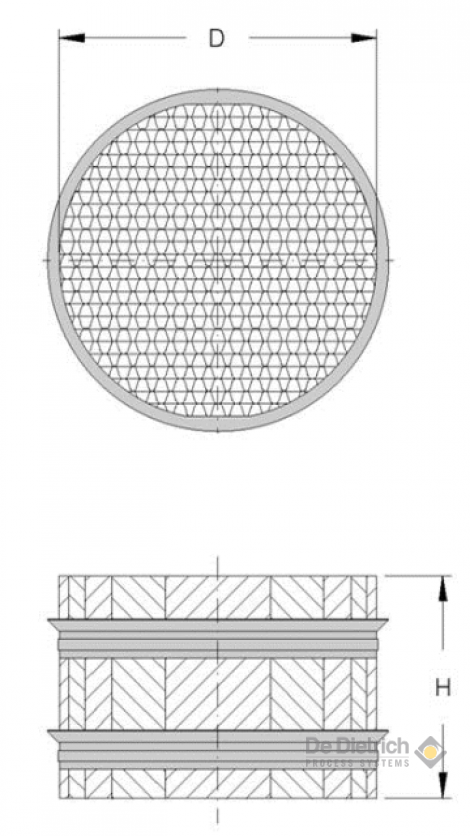

DURAPACK® Element DN300

Wall wipers

PTFE strips to boost efficiency

Liquids tend to collect and flow down on the inner walls of columns fitted with packing, an effect that prevents the liquid from wetting the packing surface and keeps most of it out of the mass transfer process. This reduces the efficiency of the column. This means that the liquid should be returned into the packing from the wall at regular intervals to restore the system’s efficiency. We have developed PTFE wall wipers and guiding funnels that either integrate into the column sections or surround the structured packings in bands.

DURAPACK® structured packing can be used either in glass columns or in columns made of other material such as glass-lined steel, PTFE-lined or Tantalum cladded materials. In QVF® glass columns up to a nominal width of DN1000 the gap between the packing and the inner column wall is closed by the standard wall wipers. Special precision bore glass pipes are not required. Using other columns material the inner diameter must be well defined to cope with the gap by the standard wall wipers.

All packaging elements have a height of 200mm. Smaller heights are available upon request. Up to a nominal width of DN300 the packaging elements have two wall wipers, for DN450 and above one wall wiper per layer is sufficient. DURAPACK® segments with flexible wall wipers can be installed in standard glass column.

Patented wall wipers

.

Technical data

- For columns diameter: DN100 up to DN2400 and more

- Max. packing height per support tray: 5m = 25 layers each 200mm

- Material: borosilicate glass 3.3, PTFE/FEP/tantalum

- Specific surface: 300 m²/m³

- Density: 400 kg/m³

- Free area: 80%

- Slope: 45°

- Surface: fire polished, nonporous, non- adhesive, smooth

- Max. shock temperature: 120°K

- Thermal coefficient of linear expansion: ca. 3,25 x 10-6/K

Single DURAPACK® element

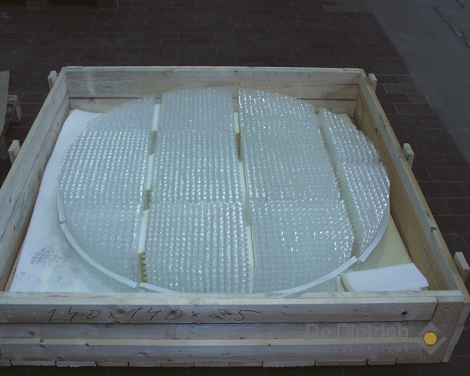

Packing beds

The height of the packing elements for all diameters is 200mm. The DURAPACK® with the nominal diameter DN100 to DN450 is one single element and can therefore be placed on a support ring. Packings with a nominal diameter of DN600 or more are divided into individual segments, and therefore require a tray or grid as support for the packing bed.

Due to the segmentation there are no limits to larger diameters. QVF® glass columns are availabe up to DN1000, DeDietrich® glass-lined columns are manufactured to the nominal diameter of up to DN2400. The maximum packing height per support tray is 5m.

Segmented DURAPACK® DN1300

Glass column DN600 with DURAPACK® packing bed

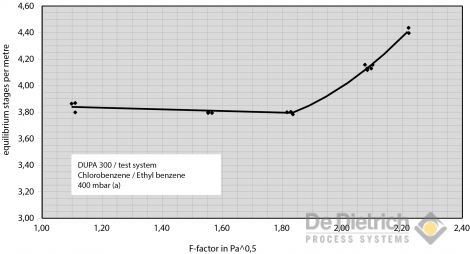

Performance for distillation

Separation efficiency

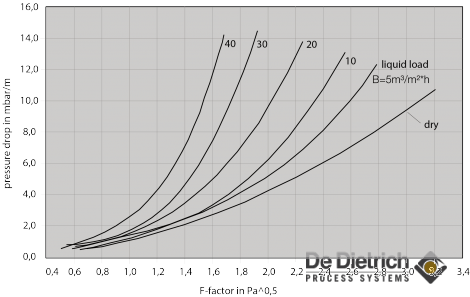

Pressure drop

Performance for extraction

To generate the largest possible mass transfer area for the liquid/liquid mass transfer of an extraction process the packing should be wetted by the continuous phase. As mostly the aqueuos phase is the continuous phase the hydrophilic and very smooth firepolished surface of borosilicate glass 3.3 is rather suitable.

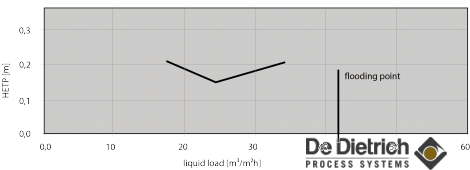

Separation efficiency

The extraction experiments have been carried out in a pulsed column with the test mixture toluene/acetone/water.

During these experiments the flooding point has been determined by an amplitude of 8mm and a frequency of 100min-1.

The number of stages is measured with a load of 80%, 60% and 40%.

Scale-up factors for larger column diameters should be considered according to relevant methods.