Contained drum unloading increases safety in work environment

OVERVIEW

De Dietrich Process Systems’ powder handling technology is most commonly used to provide a safer work environment for operators and plant personnel.

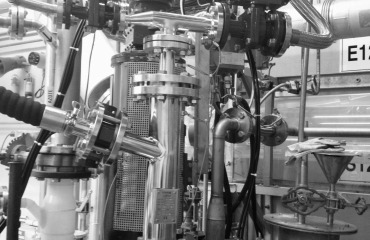

So, when we were approached by an existing customer and asked to assist them with improving containment of a highly toxic and reactive powder while charging it from drums into their reactor, we immediately set to work designing a system that would meet this primary goal, as well as several other secondary considerations.

Following factory testing, installation and start-up, the completed system met all the customer’s requirements for operator safety, process control and material containment.

ABOUT

For almost 50 years, this customer has provided innovative solutions to diffi cult applications involving the production of Hydrotopes, Acid Catalysts and Naphthalene Sulfonates. As with many existing chemical production facilities, they relied heavily on PPE, and “homemade” equipment to provide operator safety and material containment.

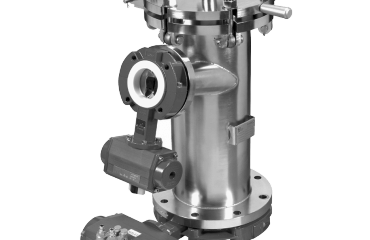

However, when a new building expansion was proposed, they recognized the opportunity to improve on those areas by installing a pneumatic transfer system to reduce physical handling of, and exposure to this material during reactor charging.