Vacuum drying brings new efficiency to brake pad manufacturing

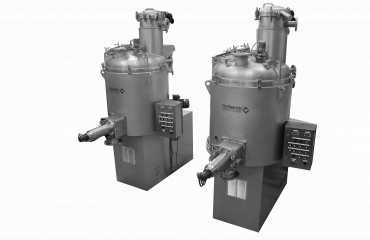

Following the identification of the drying step as the process bottleneck, early drying process trials in the De Dietrich Process Systems lab demonstrated the suitability of the Guedu pan dryer technology.

It is the only technology that was proven to successfully dry the product in the required time.

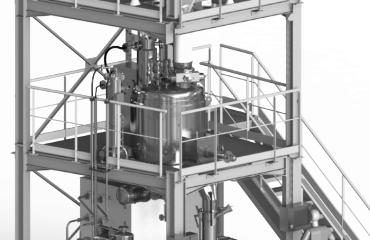

Based on the results of the trials, De Dietrich process systems sized the dryer and its utilities package (Vacuum pump, Condensers, Temperature control unit, Dust filters), and provided the integration of IBC offloading and loading.

The project was delivered in a period of 9 months, and the installation and start up on site was part of the scope of supply, leaving the customer with a real turnkey solution, and only a few recipe parameters to look after