High concentration of nitric acid

Challenges:

- The azeotrop at 68%wt -

- Clear nitric acid without NOx -

- Minimum NOx-emissions -

- Maximum yield -

- Minimum energy consumption -

Highlights

- Feed rates from 100kg/h up to 650t/d

- Concentration up to 99,8wt%

- QVF® N.A.C. Process with sulphuric acid

- Minimum energy consumption due own patented process steps

- Corrosion resistant equipment from own production of De Dietrich Process Systems

- Equipment and process liability from one single partner

- More than 100 N.A.C. installations world wide

Process

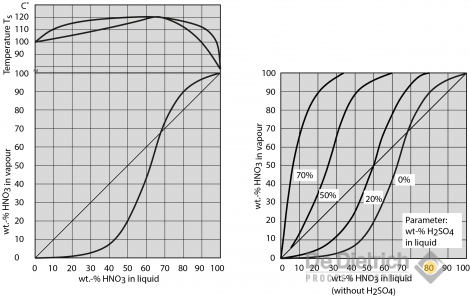

Nitric acid forms an azeotrop with water at about 68wt% of nitric acid and a boiling point at atmospheric pressure of 122°C. In order to overcome an aqueuos azeotop concentrated highly hydroscopic sulfuric acid is an ideal option as extractive agent. It can be easily separated from nitric acid as well as from water and is liquid over the complete operating temperature range which eases operation, start-up and shut down of a plant. In the below diagram it can be seen that the azeotrope disappears beyond a sulfuric acid concentration of 50wt%. In order to minimize the efforts to recycle the diluted sulfuric acid the nitric acid should be pre-concentrated.

- The system nitric acid / water (HNO3/H2O) has a maximum azeotrope at about 68 wt% and a boiling temperature of 122°C at ambient pressure.

-

When adding sulfuric acid this azeotrop disappears

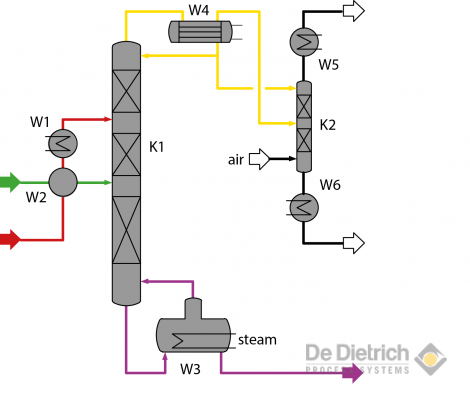

Flow chart for the extractive rectification of nitric acid in column K1 and the bleaching process step in column K2

It is therefore advantageous to pre-concentrate the weak nitric acid by simple rectification up to a value close to 68wt%. This rectification can be done at ambient pressure with the pre-concentrated nitric acid leaving the column at the bottom and the water at the top of the column. The pre-concentrated nitric acid is then concentred by a extractive rectification with sulfuric acid in column K1 providing high concentrated nitric acid, NOx and diluted sulfuric acid. The diluted sulphuric acid is reconcentrated in a sulfuric acid concentration system being part of the nitric acid concentration plant.The concentrated nitric acid containing NOx is stripped with air in a so called bleaching column K2 giving a clear nitric acid of up to 99,8wt%. The stripped NOx gases are sent to an aqueous absorption column and there converted with air under pressure to 50 - 65wt% nitric acid. The content of NOx in the vent gas can be reduced down to less than 100ppm.

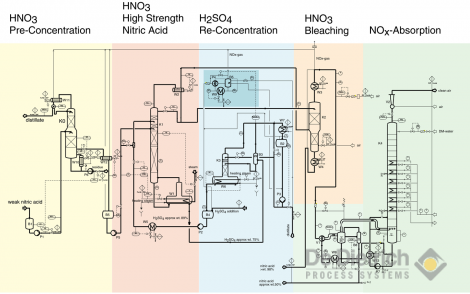

The flow chart shows the complex integration of the process steps:

- Pre-Concentration

- High Concentration

- Bleaching

- NOx-Absorption

- Sulfuric Acid Recovery

Each step has an impact on the others and hence on the overall efficiency of the process. De Dietrich Process Systems has optimized each step and their combination for decades and has patents reducing the energy consumption.

Nitric Acid Concentration Column

QVF® N.A.C. Process

Equipment Description

Hot nitric acid with a concentration above the azeotropic point is corrosive towards most kind of stainless steel. Furthermore, the advantageous use of sulfuric acid as extractive agent requires highly corrosion resistant materials. Therefore borosilicate glass 3.3 and glass-lined steel are the ideal material for the construction and reliable operation of such plants. The design and construction of components made of these materials require deep knowledge about their application in the process and the charcteristics of these materials. Heat exchangers, QVF® Horizontal Boilers, piping, column incl. packing and other internals are from our own production. De Dietrich Process Systems is therefor your unique partner taking the liability for the process as well as for the components which is extremely advantageous when realizing such corrosive processes.

Bleaching Process

Nitric acid bleaching column with clear nitric acid in lower column part

Empty line to generate FULL WIDTH

Highlights

- Feed rates from 100kg/h up to 650t/d

- Concentration up to 99,8wt%

- QVF® N.A.C. Process with sulphuric acid

- Minimum energy consumption due patented process steps

- Corrosion resistant equipment from own production of De Dietrich Process Systems

- Equipment and process liability from one single partner

- More than 100 N.A.C. installations world wide