NOx-Waste Gas Treatment

- Capturing hazardous gas -

- Production of nitric acid -

Introduction

Nitrogen oxides also called nitrous gases or NOx-gases are generated by many processes as e.g. during the reaction and concentration of nitric acid or the combustion of fossile energy sources. NOx-gases are harmfull to health but also a valuable source for the production of nitric acid.

Gases with a low content of NOx as they are e.g. generated during a combustion process are mostly converted with ammonia via catalyzed processes into nitrogen and water.

In case of higher NOx concentrations the gases are mostly guided through aqueous absorption columns where the aim can be to remove or scrubb the NOx from the waste gases and/or to produce nitric acid. Scrubbers are designed and built by De Dietrich Process Systems in many dimensions and different versions as per your needs. If oxygen is not present and the scrubber is operated with an aqueous non-oxidzing media as water the NO of the NOx will pas the scrubber while other NOx are dissolved as nitrous and nitric acid or nitrites and nitrate under caustic conditions. When adding oxygen the NO will be oxidized in the gasphase to NO2 to become nitric acid and is dissolved in water which is the common way to produce nitric acid. When adding oxidizing agents to the liquid phase as hydrogenperoxid or potasium permanganate nitrites are oxidized to nitrates improving the scrubbing process. Such semi-batch wise operated absorption systems are commonly provided by us when periodically operated processes as the dissolving process of metals with nitric acid generate the NOx-waste stream.

Atmospheric NOx-Scrubber

With air resp. oxygen the conversion of NOx into nitric acid can be realised in a quantitive manner advantageously at a higher pressure, which is basically also the common method for the syntheses of nitric acid based on the ammonia oxidation. Such continoulsy operated NOx-Absorption towers are normally supplied by us along with nitric acid concentration plants to reduce NOx-emissions below regulated values and to improve the efficency of the over all nitric acid concentration process.

The solutions we provide are:

- Laboratory and pilot scale atmospheric NOx-Scrubbers mostely operated semi-batch wise to clean waste gases

- Pilot and production scale atmospheric NOx-Absorption units operated semi-batch wise or continuously to capture nitrous gases

- Production scale pressurized NOx-Absorption towers to produce continuously nitric acid

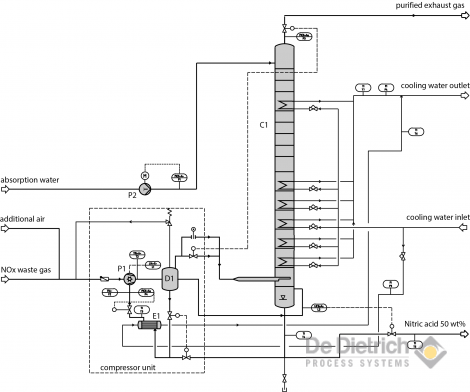

Process to convert NOx into nitric acid with air

Process Flow Chart of QVF® NOx-Pressure absorption to produce nitric acid

Heat removal in the column is a significant issue due to the exothermal reaction; DeDietrich Process Systems has therefore equipped them with specially designed cooled trays.

Case Study

One of the largest NOx pressure absorption columns that DeDietrich Process Systems has built weighs 41t, has a height of 35m and a diameter of 1.900mm.

DeDietrich Process Systems delivers pressure absorption plants in accordance with valid standards, such as:

- AD2000 / PED

- ASME

- US Stamp

- China Stamp

Reference plants can be found around the world.

Picture shows NOx-Column during shipment at night

Highlights

- NOx-Conversion into Nitric Acid with air -

- High concentration of produced nitric acid -

- NOx emissions lower than 100ppm -

- About 50 installations world wide -